Mixer

A technology of mixing and stirring motors, which is applied in mixers, mixers with rotating mixing devices, and dissolving directions, can solve the problems of simple structure of mixing blades, and it is not easy for fertilizers to be turned over and evenly mixed, and achieves low waste of resources and work efficiency. High efficiency and good quality of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

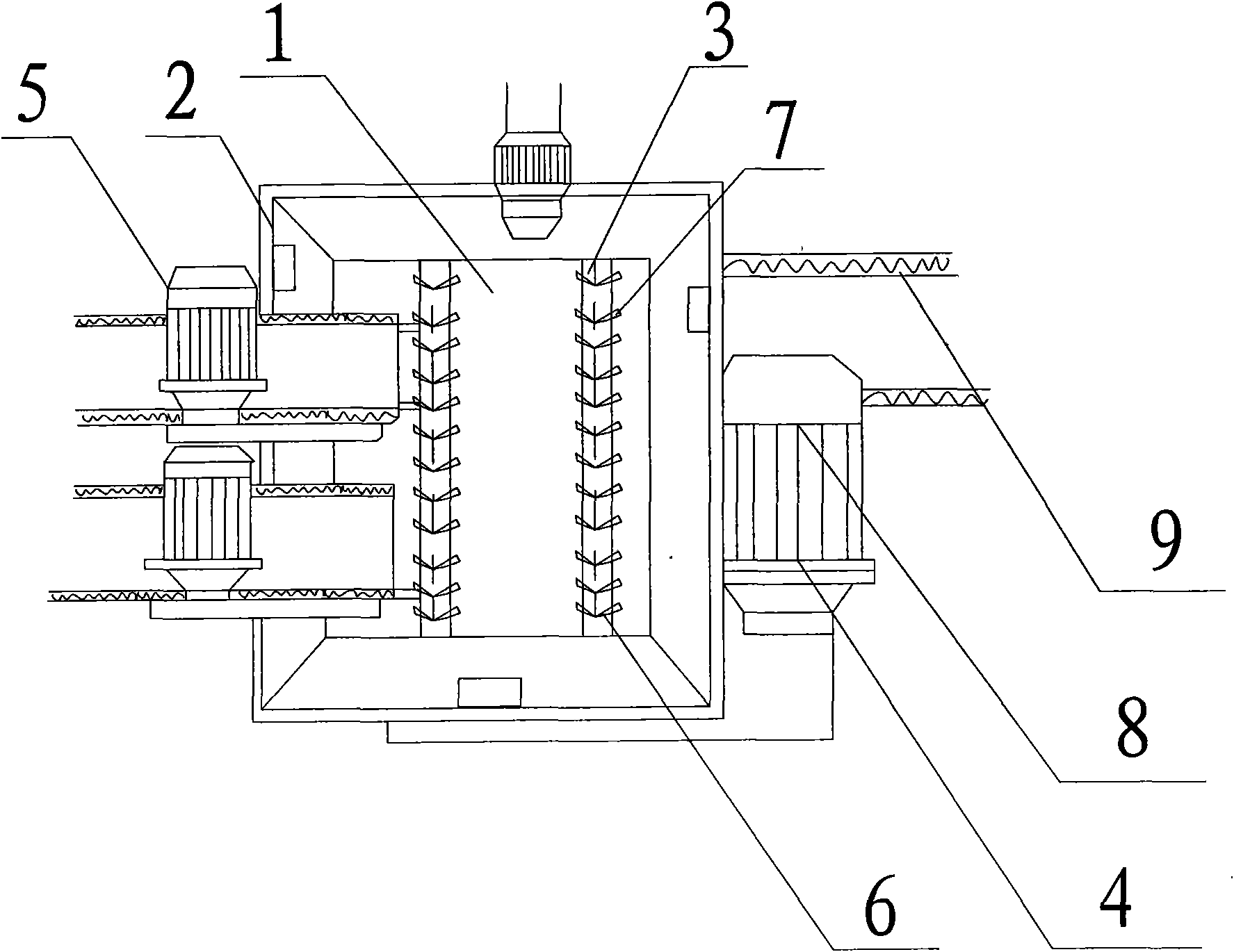

[0012] like figure 1 As shown, the mixing machine of the present invention includes a feed box 1, a stirring system 3 and a conveying system 4, a stirring system 3 is installed in the feed box 1, and the stirring system 3 includes a stirring motor 5 and two stirring shafts 6. A number of stirring blades 7 are evenly arranged on the two stirring shafts 6. The conveying system includes a conveying motor 8 and a conveyor belt 9. The shape of the stirring blades 7 is an "S" structure, which is different from the original stirring Compared with the blade 7, this structural design increases the contact area between the stirring blade 7 and the fertilizer, so that the fertilizer can be stirred more fully and evenly. The lines on the conveyor belt 9 are "S" type lines.

[0013] During the use of the present invention, due to its special structural features, the present invention has good transmission effect and obvious stirring effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com