Correcting device and application method

A technology of a deviation correction device and a support seat, which is applied in the field of deviation correction devices to achieve the effects of strong applicability, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

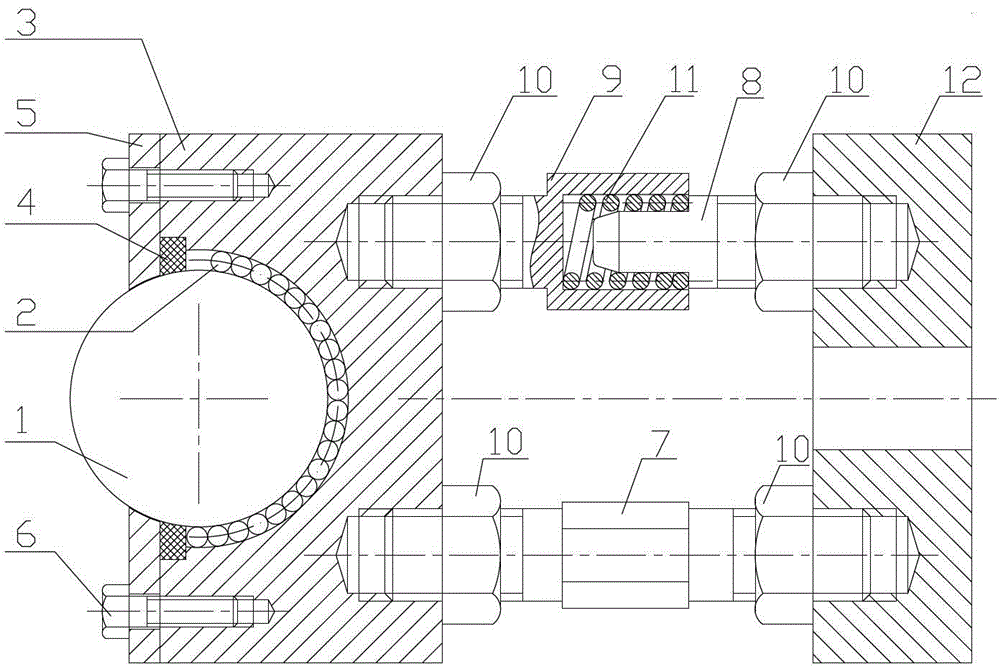

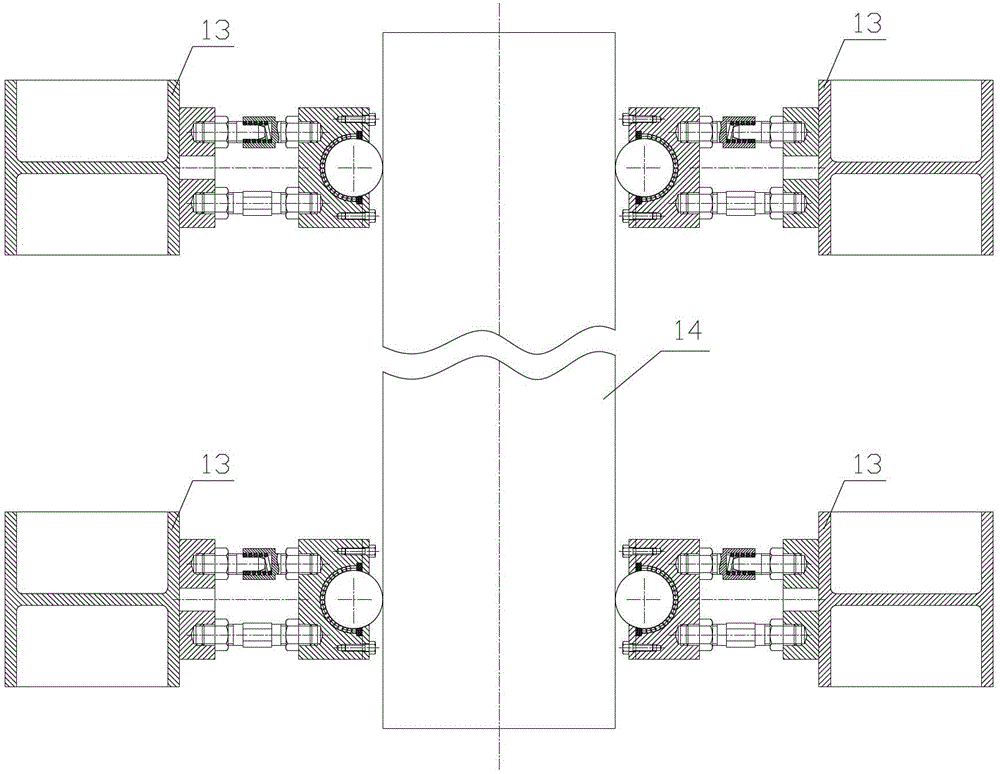

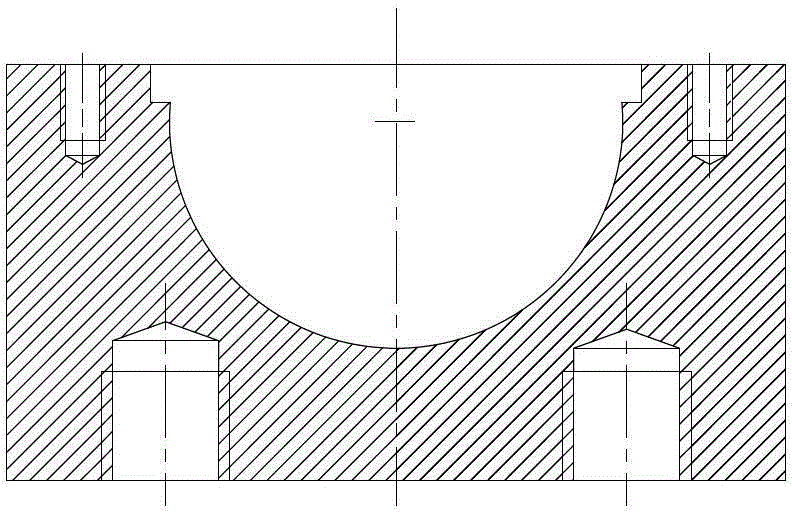

[0024] see figure 1 , a cross-sectional view of a deviation correction device provided by an embodiment of the present invention, including a universal ball guiding structure and a screw adjustment mechanism. The universal ball guiding structure includes a universal ball 1, a support seat 3, balls 2, a skeleton sealing ring 4 and The end cover 5, wherein the universal ball 1 is slidingly connected with the support seat 3 through the ball 2, there is a sealing groove on both sides inside the support seat 3, and a skeleton sealing ring 4 is respectively installed in the sealing groove, and the end cover 5 passes through the end cover The bolt 6 is fixedly connected with the support seat 3, and the skeleton sealing ring 4 is limited in the sealing groove; the ball 2 is used to support and guide the universal ball 1, and the interior of the support seat 3 is hemispherical (see image 3 ), the support seat 3 is used to install the ball 2 and the universal ball 1.

[0025] The scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com