Method for repairing damage of non-work surface of roller

A non-working surface and damage repair technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of high repair cost, high requirements, and technical difficulty, and achieve the effect of reducing dependence and reducing repair cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

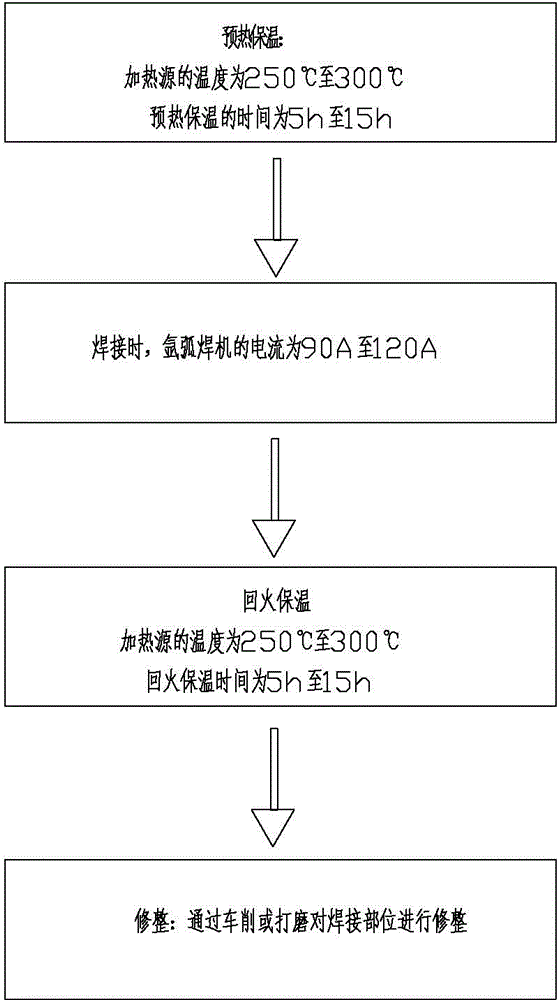

[0021] Below in conjunction with embodiment and attached figure 1 The present invention is further described:

[0022] as attached figure 1 As shown, the non-working surface damage repair method of the roll is carried out according to the following steps: the first step, preheating and heat preservation: after removing the fatigue layer or defect on the surface of the damaged part of the non-working surface of the roll, the damaged part is locally heated, during the heating process Insulate the heated part; the second step, welding: after stopping the preheating, weld the damaged part of the non-working surface of the roll at intervals of 5mm to 100mm, and quickly tap the damaged part to restore the damaged part to its original shape as much as possible before continuing Welding; the third step, tempering and heat preservation: after the welding is completed, locally heat the welded part, and heat the heated part during the heating process; the fourth step, trimming: after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com