Discharging device and stirring equipment

A technology of a discharging device and a vibrating device, which is applied in the field of mixing machinery, can solve the problems of blocking the discharge port and unsmooth feeding, and achieves the effects of increasing fluidity, smooth feeding, and good anti-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

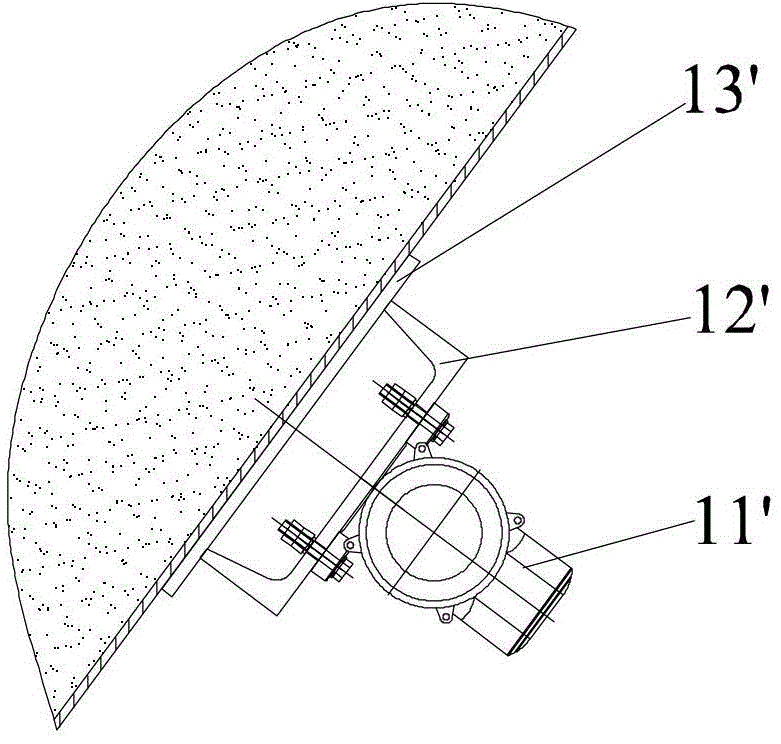

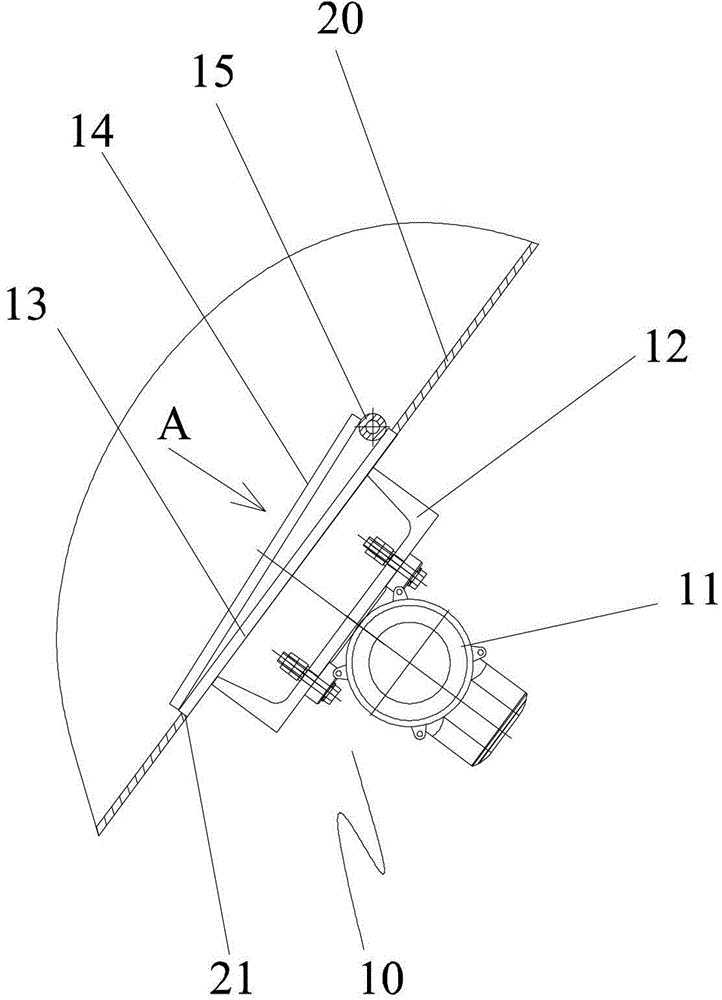

[0025] like Figures 2 to 4 As shown, according to the first embodiment of the present invention, a discharge device includes a discharge bin 20 and a vibration device 10 fixedly arranged on the side wall of the discharge bin 20 . An opening 21 is provided on the side wall of the discharging bin 20 , and the vibrating device 10 is arranged at the opening 21 of the discharging bin 20 .

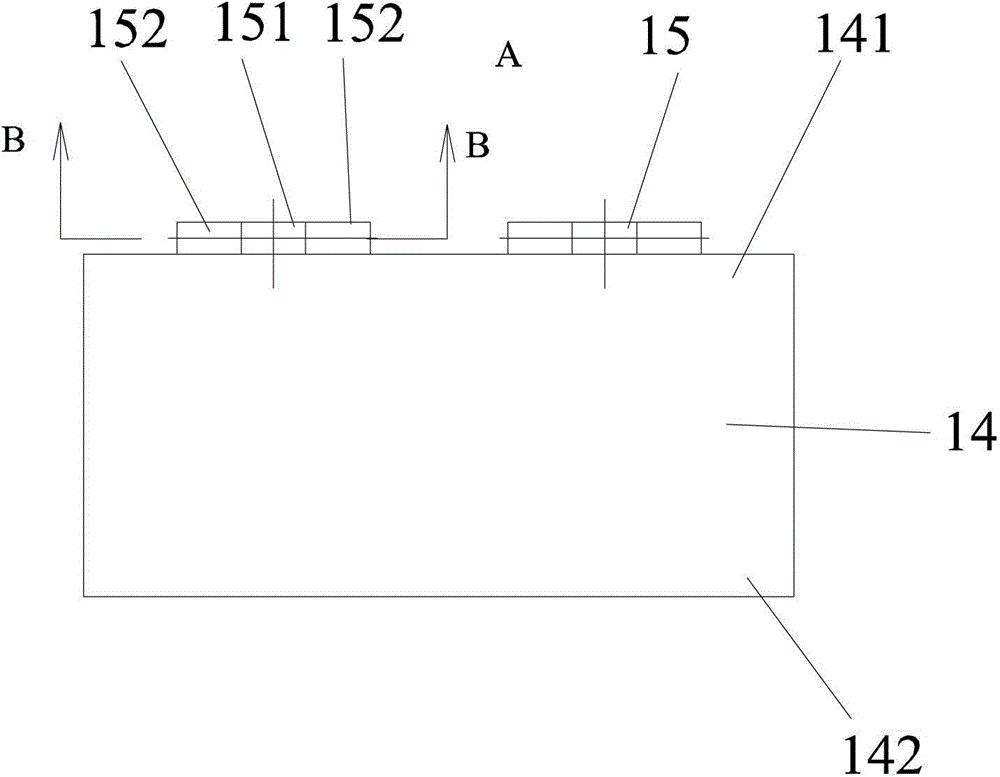

[0026] The vibration device 10 includes a vibrator 11 , a vibrator support and a movable plate 14 . Wherein the vibrator 11 and the movable plate 14 are respectively fixedly arranged on two opposite sides of the vibrator support, and the movable plate 14 is movably arranged in the discharge bin 20, when the material body enters from the entrance of the discharge bin 20 and passes through When the movable plate 14 is at the position, under the vibration of the vibrator 11, the movable plate 14 will be in an active state, thereby shaking off the material body on the movable plate 14, preventing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com