A system and method for laser-assisted preparation of bulk amorphous alloys

An amorphous alloy, laser-assisted technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of material performance degradation, and achieve the effects of high work efficiency, fast heating and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

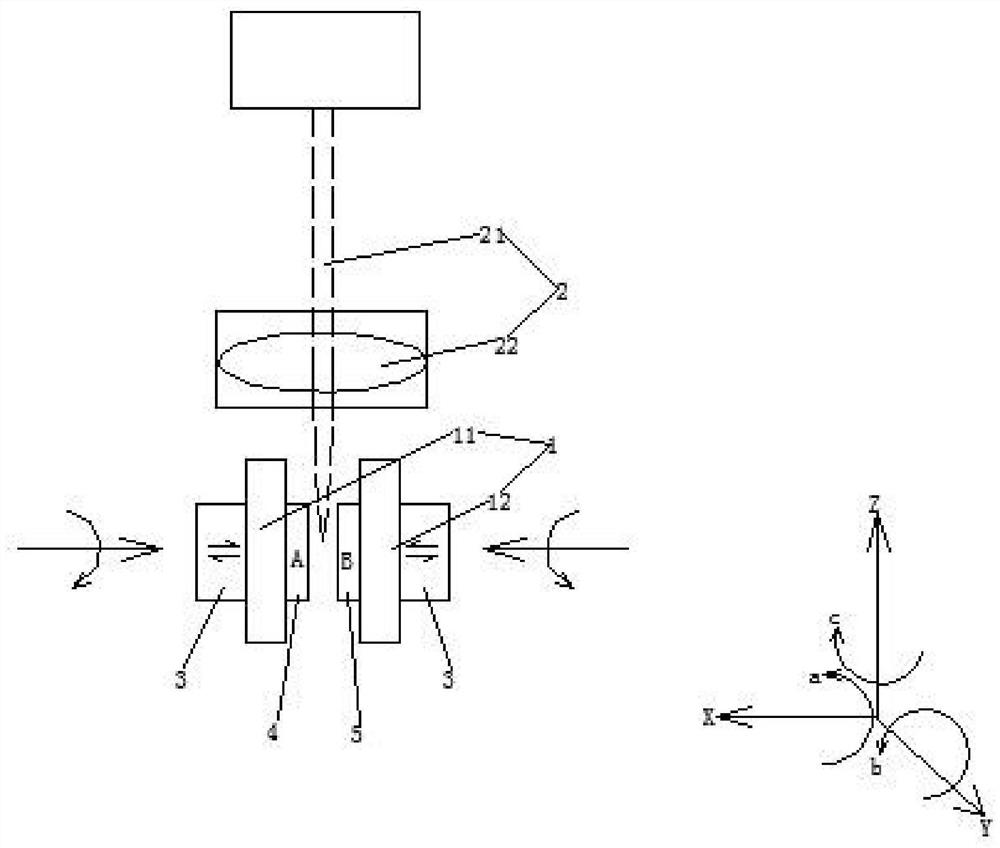

[0055] In Example 1, such as figure 1 , the amorphous alloy A4 and the amorphous alloy B5 are clamped on the first clamping turntable 11 and the second clamping turntable 12 of the clamping system 1, and the initial processing position of the workpiece is adjusted. The composition of the amorphous alloy A4 is Zr57Nb5Cu15.4Ni12.6Al10. Among them, Tg is 405°C, and Tx is 470°C. The composition of the amorphous alloy B5 is Zr58.5Nb2.8Cu15.6Ni12.8Al10.3. Among them, Tg is 400°C, and Tx is 480°C. According to the calculation of the cross supercooled liquid phase region of amorphous alloy A4 and amorphous alloy B5, the processing temperature is set to 450°C, and then the laser beam with a wavelength of 1030nm, a pulse width of 170fs, a power of 4W, and a frequency of 100kHz is calculated. Preheat the working contact interface between crystal alloy A4 and amorphous alloy B5, the clamping system 1 works, the first clamping turntable 11 rotates counterclockwise along the direction a,...

Embodiment 2

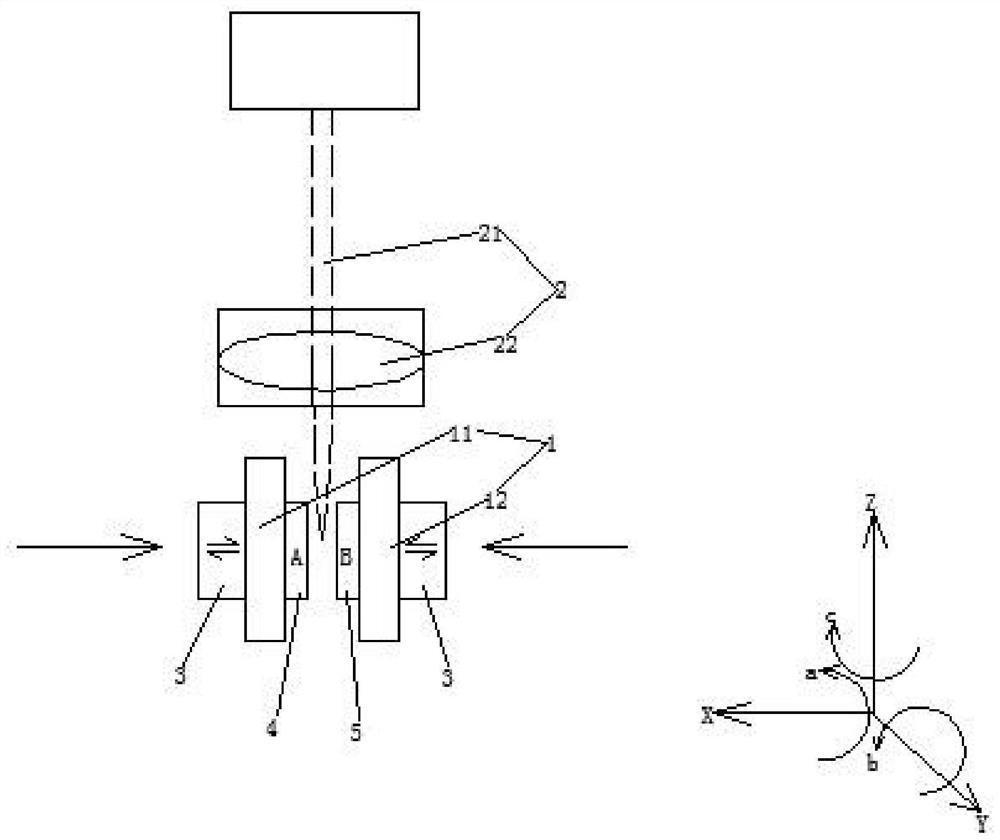

[0057] In Example 2, such as figure 2 , clamp the amorphous alloy A4 and the amorphous alloy B5 on the first clamping turntable 11 and the second clamping turntable 12 of the clamping system 1, adjust the initial processing position of the workpiece, the amorphous alloy A4 and the amorphous alloy The components of B5 are all Pd43Ni10Cu27P20. Among them, Tg is 305°C and Tx is 406°C. According to the calculation of the cross supercooled liquid phase region of amorphous alloy A4 and amorphous alloy B5, the processing temperature is set to 380°C, and then the output wavelength of the laser beam is 1064nm, the pulse width is 240ps, the power is 3W, and the frequency is 200kHz. The contact interface between crystal alloy A4 and amorphous alloy B5 is preheated, the clamping system 1 works, the first clamping turntable 11 moves in relative translation along the X direction and the second clamping turntable 12 is squeezed, and at the same time, the ultrasonic system 3 works , the po...

Embodiment 3

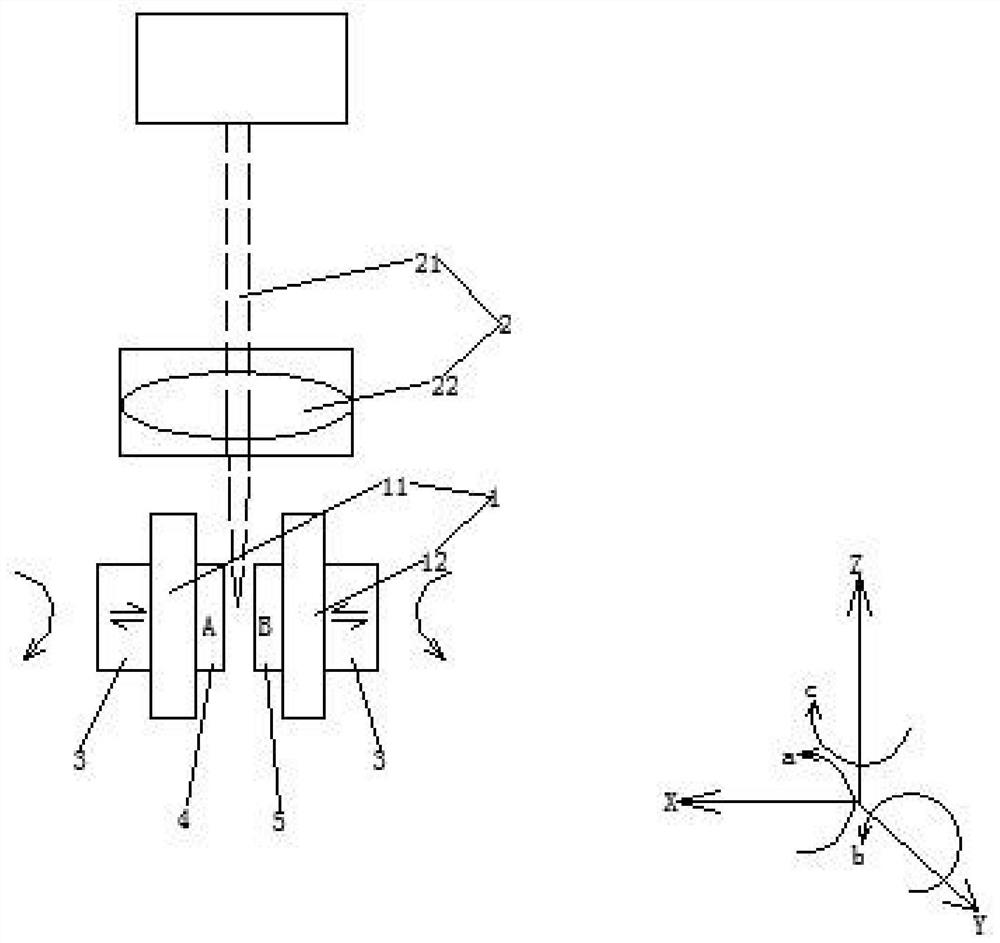

[0059] In Example 3, such as image 3 , clamp the amorphous alloy A4 and the amorphous alloy B5 on the first clamping turntable 11 and the second clamping turntable 12 of the clamping system 1, adjust the initial processing position of the workpiece, the amorphous alloy A4 and the amorphous alloy The components of B5 are all Ca65Li14.54Mg12.46Zn8. Among them, Tg is 35°C and Tx is 105°C. According to the calculation of the cross supercooled liquid phase region of amorphous alloy A4 and amorphous alloy B5, the processing temperature is set to 50°C. Due to the low temperature, the laser beam output is 0W at this time, the clamping system 1 works, and the first clamping The turntable 11 rotates counterclockwise along the direction a at a rotation speed of 200rpm, and the second clamping turntable 12 rotates clockwise along the direction a at a rotation speed of 200rpm, and heat is generated by friction. At the same time, the ultrasonic system 34 is working with a power of 1000W, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com