A rare earth ion-doped fluorotellurate optical temperature sensing fiber and its preparation method

A technology of rare earth ions and sensing optical fiber, which is applied in the field of optical fiber, can solve the problems of temperature sensitivity test accuracy drop, increase economic cost, and lower signal strength, and achieve the effects of low phonon energy, good physical properties, and high temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

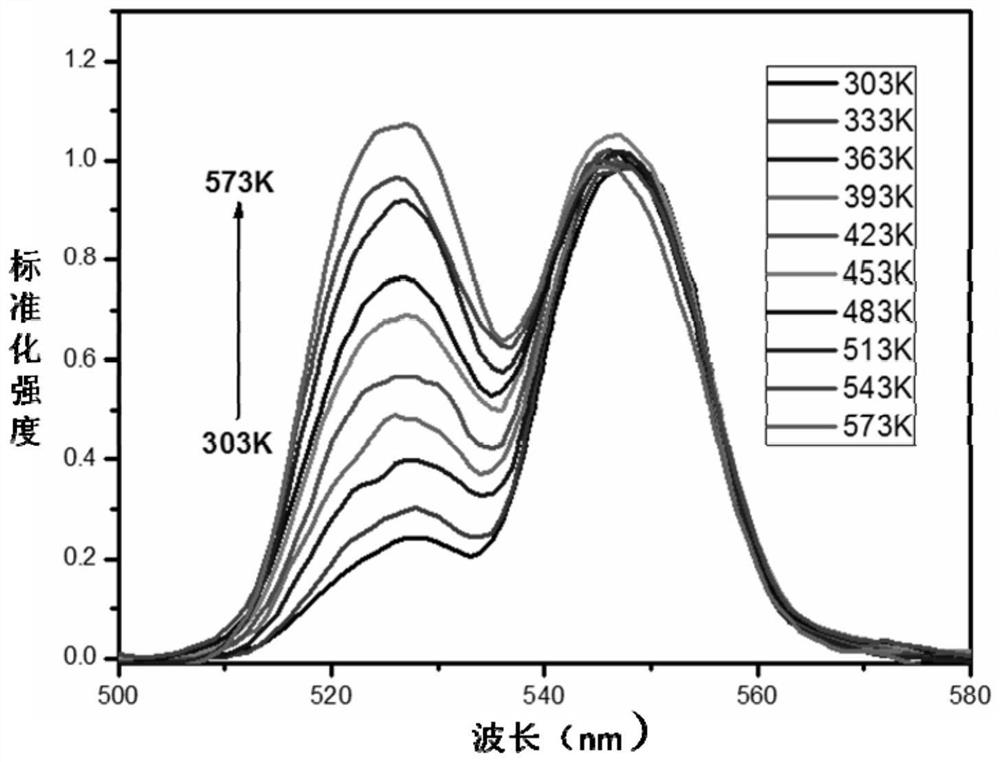

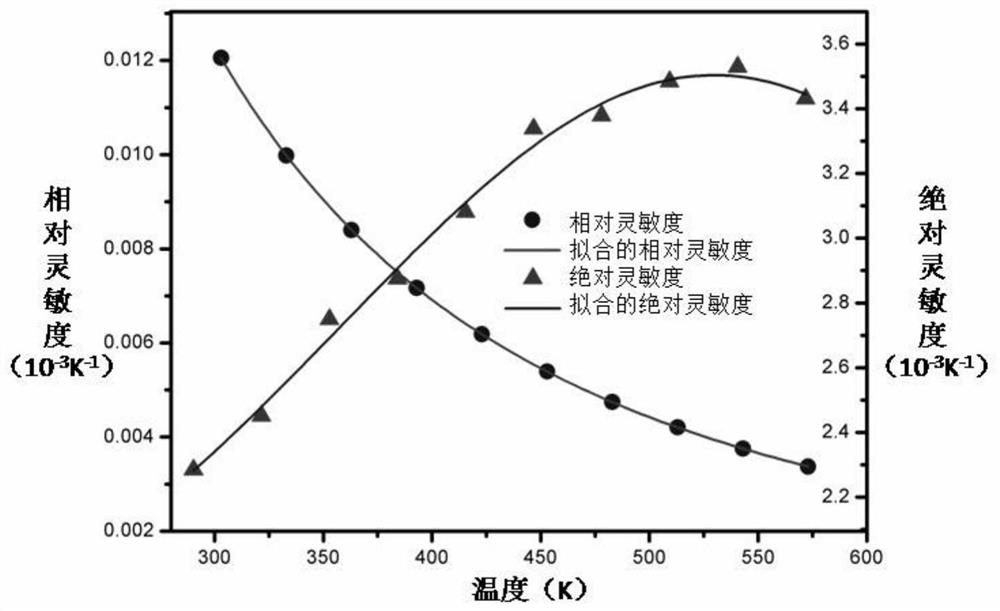

Examples

Embodiment 1

[0042] The preparation of the rare earth ion-doped fluorotellurate optical temperature sensing fiber in this embodiment, the specific steps are as follows:

[0043] 1. Preparation of fluorotellurite-clad glass tube

[0044] (a) The cladding glass adopts the following formula, calculated by component molar ratio:

[0045] TeO 2 : 76%

[0046] ZnF 2 : 12%

[0047] KF: 12%;

[0048] (b) Take high-purity powder raw material 300g by component formula, after fully mixing in agate mortar, pour in corundum crucible, cover lid;

[0049](c) Transfer it to a 950°C high-temperature electric furnace for melting for 30 minutes, and preheat the forming mold to 300°C in an annealing furnace in advance, and transfer it to the air to cool it for a while when the glass liquid is discharged, until the viscosity is high Pour it very slowly into the preheated forming mold, and then quickly transfer the mold to the annealing furnace for annealing;

[0050] (d) Set the annealing system, keep w...

Embodiment 2

[0069] The preparation of the rare earth ion-doped fluorotellurate optical temperature sensing fiber in this embodiment, the specific steps are as follows:

[0070] 1. Preparation of fluorotellurite-clad glass tube

[0071] (a) The cladding glass adopts the following formula, calculated by component molar ratio:

[0072] TeO 2 : 76%

[0073] ZnF 2 : 12%

[0074] KF: 12%;

[0075] (b) Take high-purity powder raw material 300g by component formula, after fully mixing in agate mortar, pour in corundum crucible, cover lid;

[0076] (c) Transfer it to a 950°C high-temperature electric furnace for melting for 30 minutes, and preheat the forming mold to 300°C in an annealing furnace in advance, and transfer it to the air to cool it for a while when the glass liquid is discharged, until the viscosity is high Pour it very slowly into the preheated forming mold, and then quickly transfer the mold to the annealing furnace for annealing;

[0077] (d) Set the annealing system, keep ...

Embodiment 3

[0095] The preparation of the rare earth ion-doped fluorotellurate optical temperature sensing fiber in this embodiment, the specific steps are as follows:

[0096] 1. Preparation of fluorotellurite-clad glass tube

[0097] (a) The cladding glass adopts the following formula, calculated by component molar ratio:

[0098] TeO 2 : 84%

[0099] ZnF 2 :8%

[0100] KF: 8%;

[0101] (b) take high-purity powder raw material 400g by component formula, after fully mixing in agate mortar, pour in corundum crucible, cover lid;

[0102] (c) Transfer it to a high-temperature electric furnace at 920°C for melting for 40 minutes. At the same time, preheat the forming mold to 300°C in the annealing furnace in advance. When the glass liquid is discharged, first transfer it to the air and cool it for a while. Pour it very slowly into the preheated forming mold, and then quickly transfer the mold to the annealing furnace for annealing;

[0103] (d) Set the annealing system, keep warm at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com