Red and blue light photosynthetic light-conversion glass capable of being activated by blue-violet light and microwave founding method

A glass and melting technology, used in glass manufacturing equipment, glass production, glass furnace equipment, etc., can solve the problems of easy deterioration, difficult recycling, and spectral mismatch of luminescent materials and plastic films, and it is easy to achieve melting process parameters. Control, stable luminous performance, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

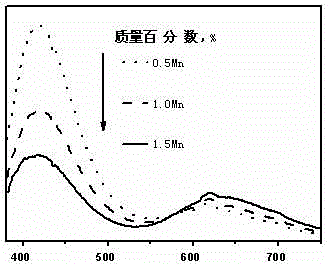

Embodiment 1

[0016] The raw material selected for the raw material mixture is SiO 2 , Mass percentage purity 99.5-99.99%, particle size D 50 Value is 50 nanometers; H 3 BO 3 , The mass percentage purity is 99.5%, the particle size is D 50 Value is 0.5 microns; BaCO 3 The mass percentage purity is 99.5%, particle size D 50 Value is 0.5 microns; MnCO 3 The mass percentage purity is 99.9%, particle size D 50 Value is 0.5 microns; Eu 2 O 3 The mass percentage purity of 99.9%, particle size D 50 Value is 20 nm 。 The raw materials were weighed according to the glass composition of Example 1 in Table 1, and ball milled in a ball mill for 6 hours to obtain a mixture. Put the mixture into a crucible and melt it by microwave in a high temperature furnace at a temperature of 1200 degrees Celsius for 4 hours to obtain a glass melt. Pour the glass melt melted by microwave at high temperature into a preheated mold, and put it into a heating furnace for annealing. The annealing temperature is 500 degrees Ce...

Embodiment 2

[0018] The raw material selected for the raw material mixture is SiO 2 , Mass percentage purity 99.9%, particle size D 50 The value is 2 microns; H 3 BO 3 The mass percentage purity of 99.8%, particle size D 50 Value is 1.5 microns; BaCO 3 The mass percentage purity is 99.9%, particle size D 50 Value is 1.5 microns; MnCO 3 The mass percentage purity is 99.95%, particle size D 50 The value is 1.5 microns; Eu 2 O 3 The mass percentage purity of 99.99%, particle size D 50 Value is 120 nm 。 The raw materials were weighed according to the glass composition of Example 2 in Table 1, and ball milled in a ball mill for 12 hours to obtain a mixture. Put the mixture into a crucible and melt it in a high-temperature furnace by microwave at a temperature of 1300 degrees Celsius for 6 hours to obtain a glass melt. Pour the glass melt melted by microwave at high temperature into a preheated mold, and put it into a heating furnace for annealing. The annealing temperature is 700 degrees Celsius f...

Embodiment 3

[0020] The raw material selected for the raw material mixture is SiO 2 , Mass percentage purity 99.95%, particle size D 50 Value is 1 micron; H 3 BO 3 The mass percentage purity is 99.85%, particle size D 50 Value is 2 microns; BaCO 3 The mass percentage purity is 99.9%, particle size D 50 Value is 2 microns; MnCO 3 The mass percentage purity is 99.9%, particle size D 50 Value is 1 micron; Eu 2 O 3 The mass percentage purity of 99.95%, particle size D 50 Value is 150 nm 。 The raw materials were weighed according to the glass composition of Example 3 in Table 1, and ball milled in a ball mill for 24 hours to obtain a mixture. Put the mixture into a crucible and melt it by microwave in a high temperature furnace at a temperature of 1250 degrees Celsius for 8 hours to obtain a glass melt. Pour the glass melt melted by microwave at high temperature into a preheated mold, and put it into a heating furnace for annealing. The annealing temperature is 750 degrees Celsius for 6 hours. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com