Universal test machine

A universal testing machine and workbench technology, applied in the field of universal testing machines, can solve the problems such as easy deformation of the wedge-shaped mouth of the jaw seat, poor neutrality between the jaw and the jaw plate, affecting the accuracy of the test results, etc., so as to improve the test results. Accuracy, the base of the host is enlarged, the effect of increasing the safety and beauty of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

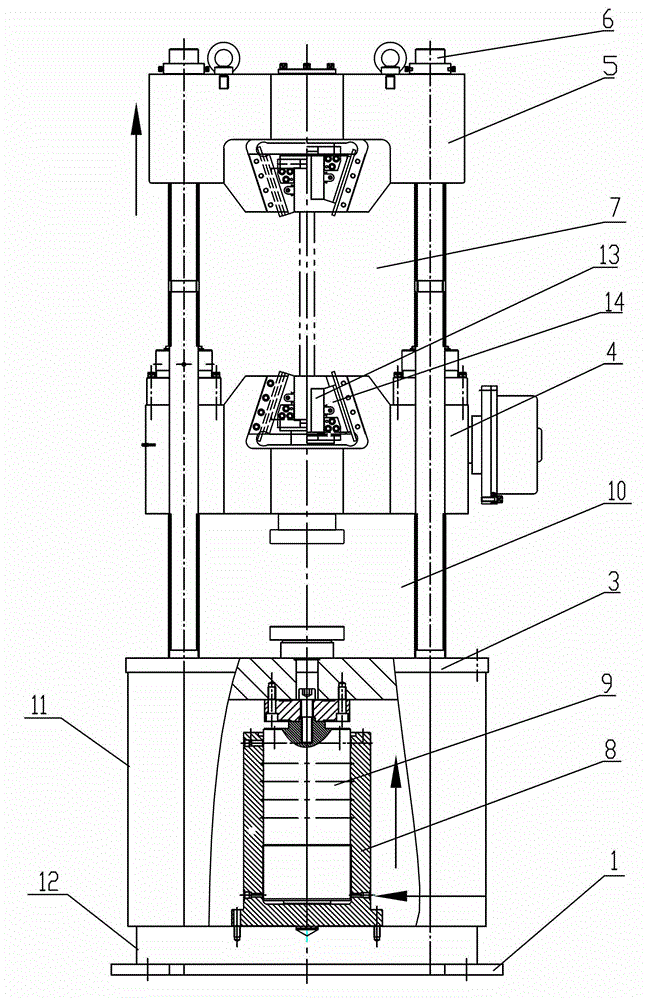

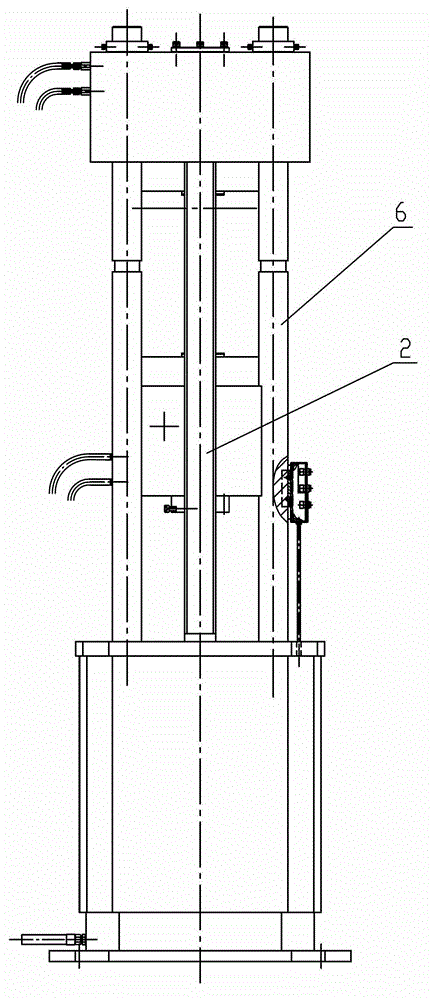

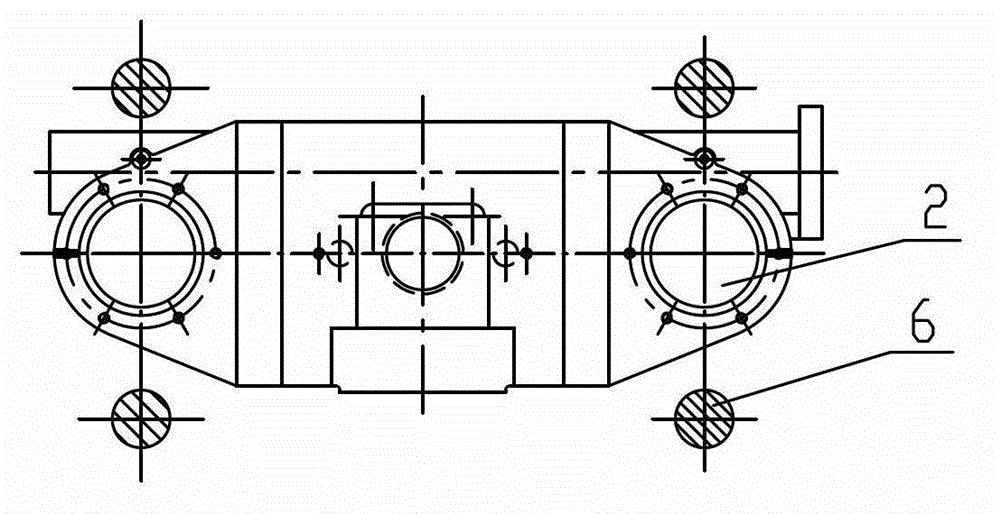

[0020] Refer to the instructions attached figure 1 Attached Picture 11 The universal testing machine of the present invention will be described in detail below.

[0021] The universal testing machine of the present invention has a structure including a workbench 3, a base 1, a column 6, a lead screw 2, an upper beam 5, and a lower beam 4. The lead screw 2 includes two left and right lead screws, and two left and right lead screws. 2 The lower end is fixed on the base 1 by a nut, and the upper end passes through the worktable 3 and is connected to the lower beam 4 through a trapezoidal thread pair to form a rigid fixed frame. The upper part of the base 1 is provided with an oil cylinder 8, and the oil cylinder 8 is equipped with a piston 9. The upper end of the piston 9 is connected to the worktable 3. The upper beam 5 and the lower beam 4 are respectively provided with a hydraulic clamping system. The hydraulic clamping system includes a jaw plate 14 and a jaw 13, and the column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com