Circuit breaker and assembling structure of three-phase linkage transmission mechanism thereof

A technology of transmission mechanism and circuit breaker, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of difficult assembly, large friction between the transmission shaft and the support plate, and increased radial force of the transmission shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

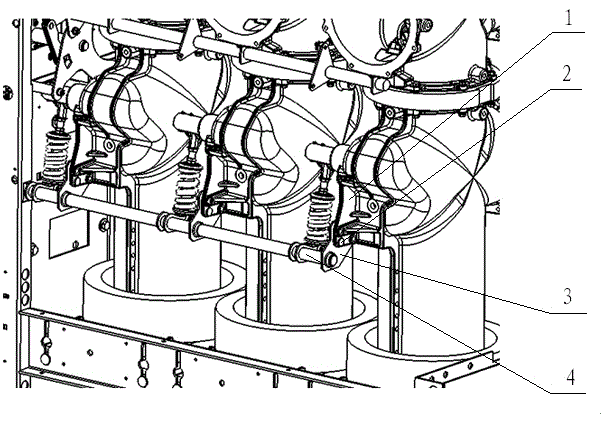

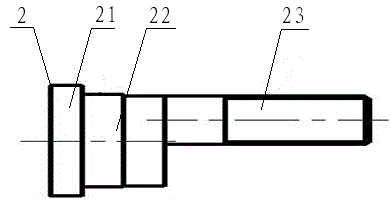

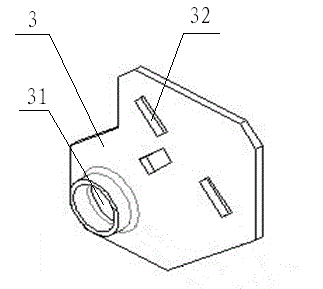

[0012] Embodiments of the circuit breaker of the present invention: as figure 1 , figure 2 , image 3 As shown, it includes a circuit breaker housing 1, on which three support plates 3 are fixed in sequence along the straight line direction through bolts 2, and the three support plates 3 are rotatably equipped with transmission shafts, and the circuit breaker housing The hole on the support plate 3 for the bolt 2 to pass through is the bolt hole, the hole on the support plate 3 for the drive shaft 4 to pass through is the assembly hole 31, and the hole for the bolt 2 to pass through is the connecting hole 32, and the above part is the prior art Or it can be realized through existing technology. The improvement of the present invention is that: the bolt 2 adopts an eccentric bolt, and a positioning column 22 coaxial with the nut 21 is integrally arranged between the nut 21 and the rod 23 of the bolt, and the positioning column 22 coincides with the bolt hole. and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com