Battery inner box and battery temperature control box employing battery inner box

A battery temperature control box and battery internal technology, applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of high labor intensity for operators, poor heat dissipation effect, hidden dangers of battery safety, etc., and achieve the purpose of increasing the heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

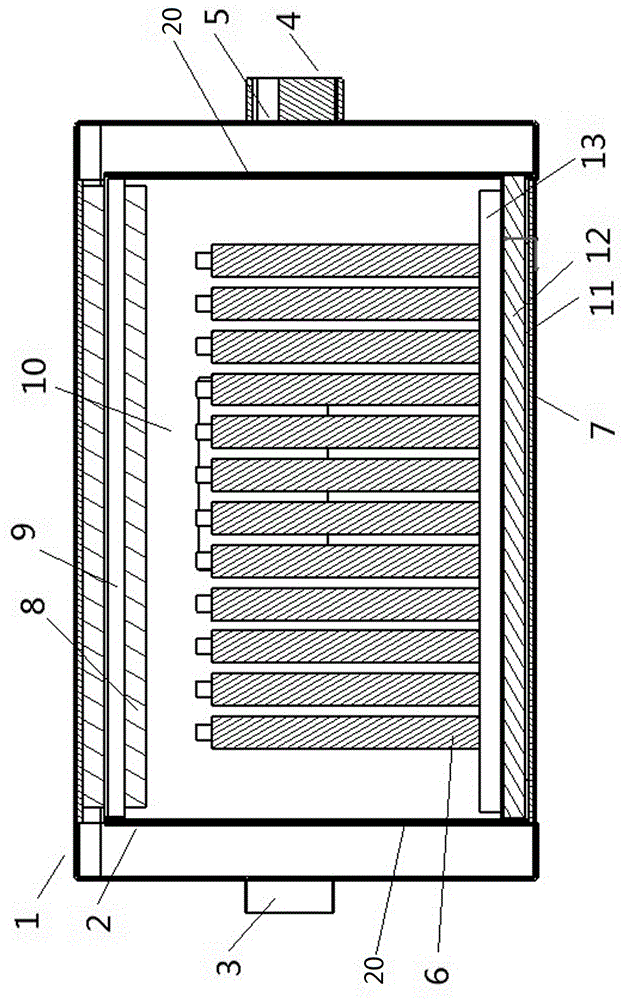

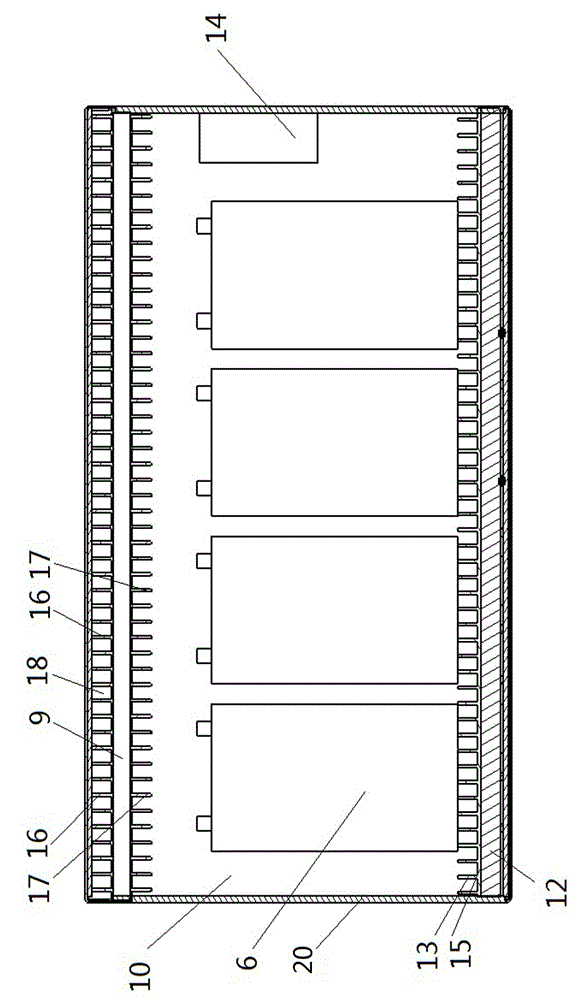

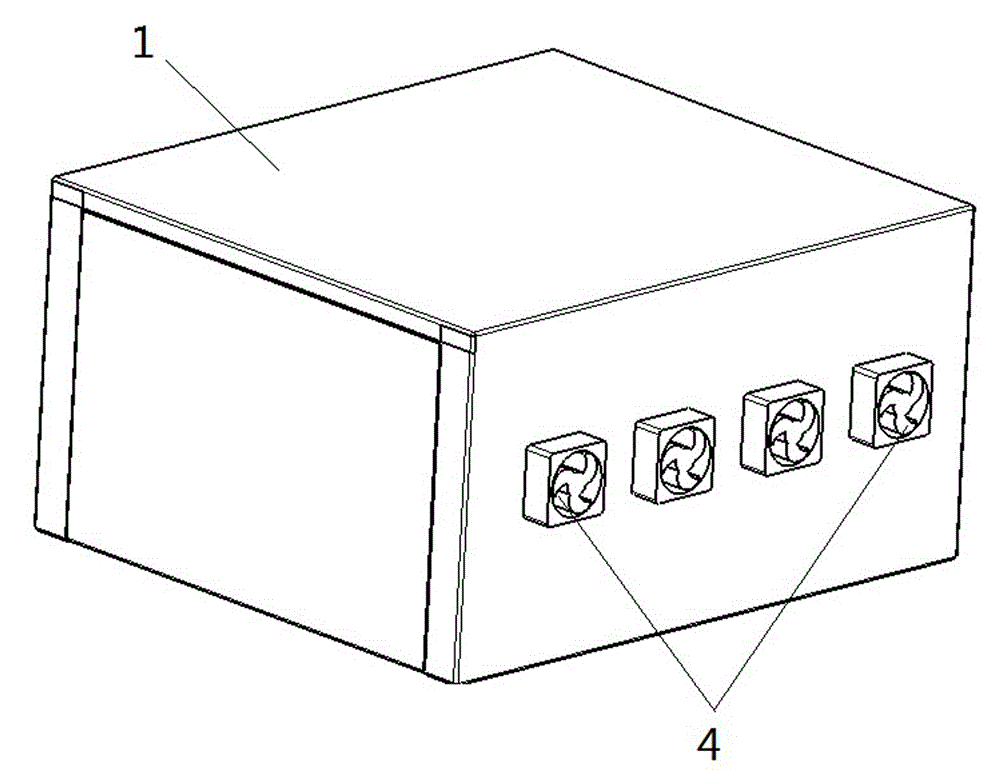

[0022] Examples of battery temperature control boxes are Figure 1~3 Shown: including the battery inner box 2 and the battery outer box 1 that is arranged on the periphery of the battery inner box 2, the battery inner box 2 includes an inner box cover plate 8 and an inner box bottom plate 7 and is arranged on the inner box cover plate 8 and the inner box Inner box side panels 20 between bottom panels 7 . The inner box cover plate 8 is made of heat-conducting material, and the inner box side plate 20 and the inner box bottom plate 7 are made of heat-insulating and flame-retardant material. Inner box cover plate 8, inner box bottom plate 7 and each inner box side plate 20 encircle the accumulator storage cavity 10 that is used to place corresponding accumulator 6 and seal, and the top and the bottom surface of inner box cover plate 8 are respectively provided with outward facing back. The heat conduction fins 16 and the inner heat conduction fins 17, the inner box cover plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com