Multi-stage switchable pilot-controlled valve arrangement

A technology of pilot control and valve device, which is applied in the direction of valve device, control valve and air release valve, valve operation/release device, etc. It can solve the problems of large volume and high cost of pipeline installation, and achieve the purpose of improving device safety and improving The effect of safety, high efficiency and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

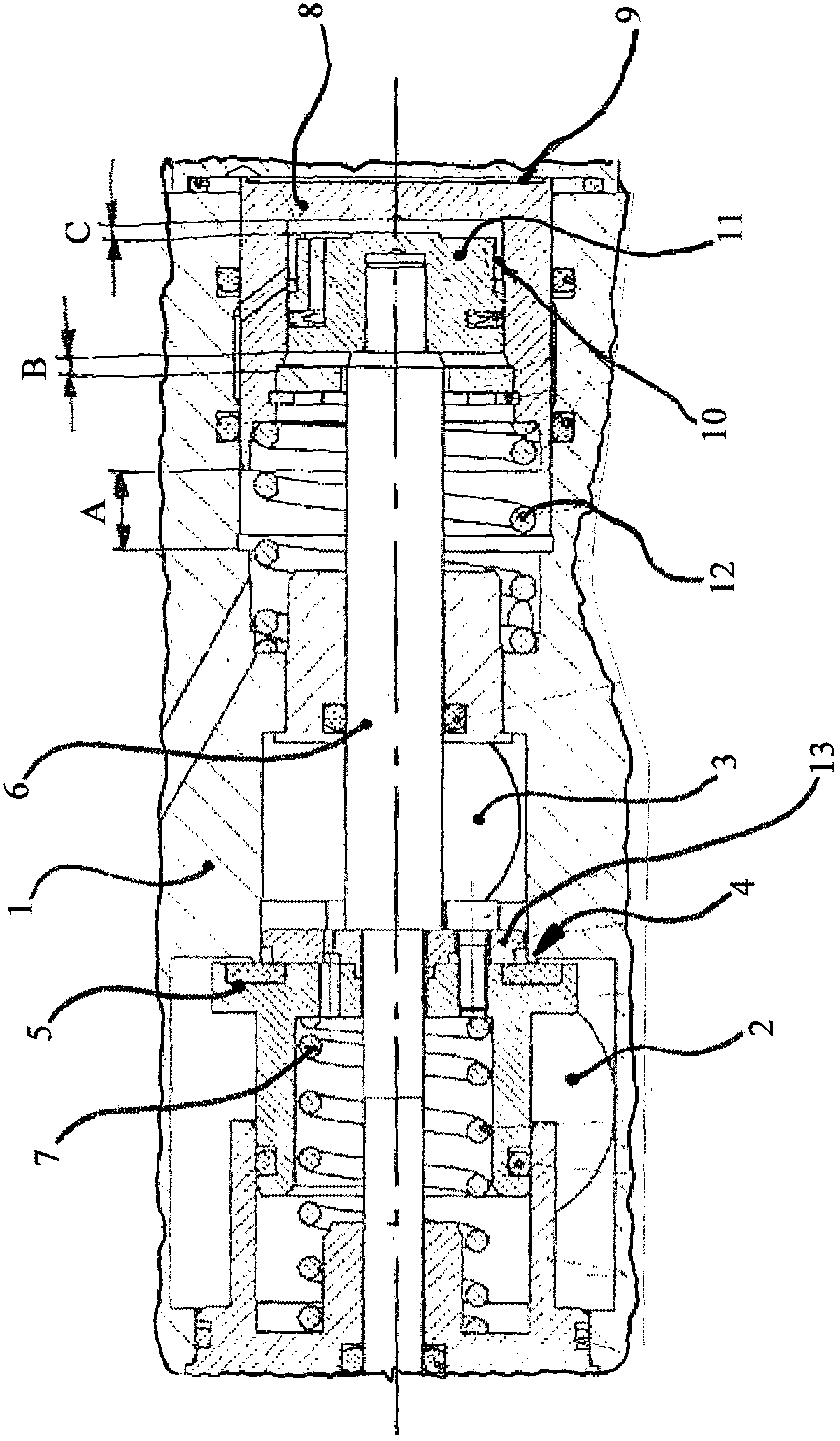

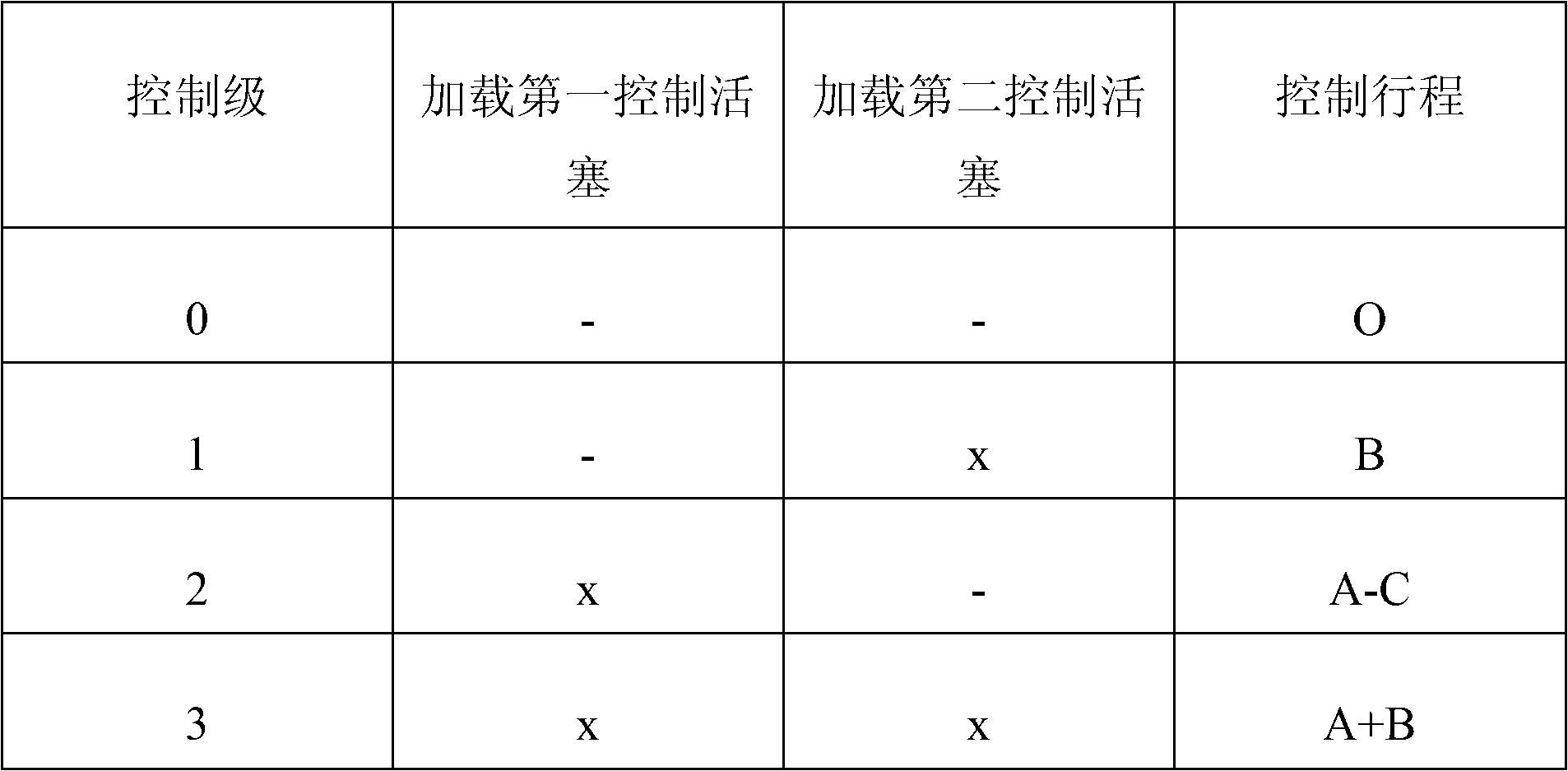

[0019] According to the illustration, the valve housing 1 (the region of the valve mechanism is only partially shown here) has a pressure supply connection 2 and a working line connection 3 . The valve mechanism has a normally closed 2 / 2 valve function, which is generated by the seat valve. The seat valve comprises a valve seat 4 fastened to the housing, which can be moved from the fully closed valve shown here by means of a coaxially extending and axially displaceable tappet 6 with its associated shut-off element 5 according to the pneumatic pilot control. The valve position passes over the throttled intermediate valve position into the open valve position. The valve return spring 7 , which is likewise integrated in the valve housing 1 , holds the shut-off element 5 of the seat valve in the closed control position during pressure-free pilot control.

[0020] The pneumatic pilot control consists of a first control piston 8 located in a first control chamber 9 formed in the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com