External circulation vacuum distillation column

A technology of vacuum rectification and external circulation, applied in the direction of fractionation, etc., can solve the problems of poor condensation effect, low collection and distribution gas velocity, poor structural firmness, etc., and achieve the effect of complete condensation and high collection and distribution gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

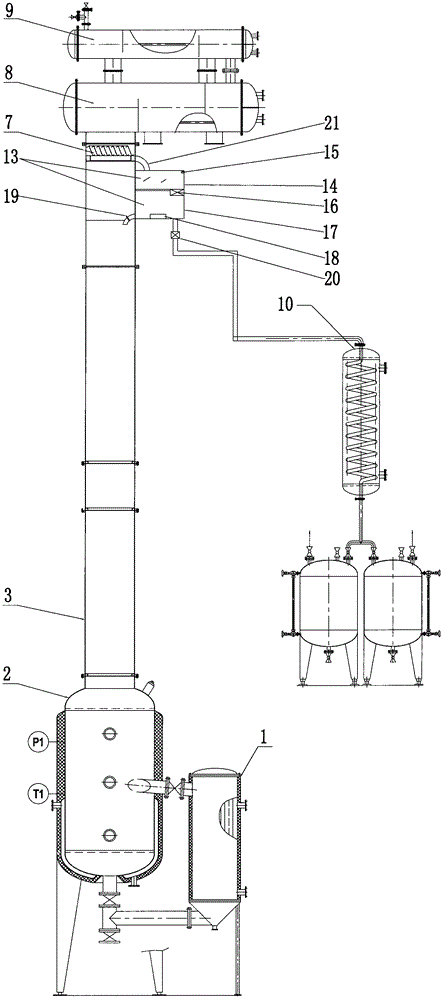

[0009] Such as figure 1 As shown, the external circulation vacuum rectification column provided by the present invention includes a heater 1, a distillation pot 2, a distillation tower 3, a liquid collector 7, a condenser, a coil cooler 10 and a collection tank 12 that are sequentially conducted, and the distillation The tower 3 is directly connected to the condenser, where the heater is a tube-and-tube cycle heating, with fast heating speed and high efficiency. The condenser includes a first condenser 8 and a second condenser 9 .

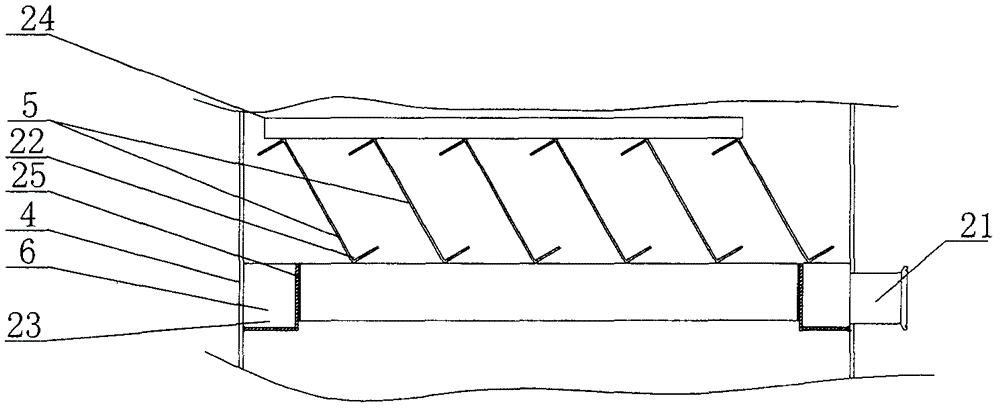

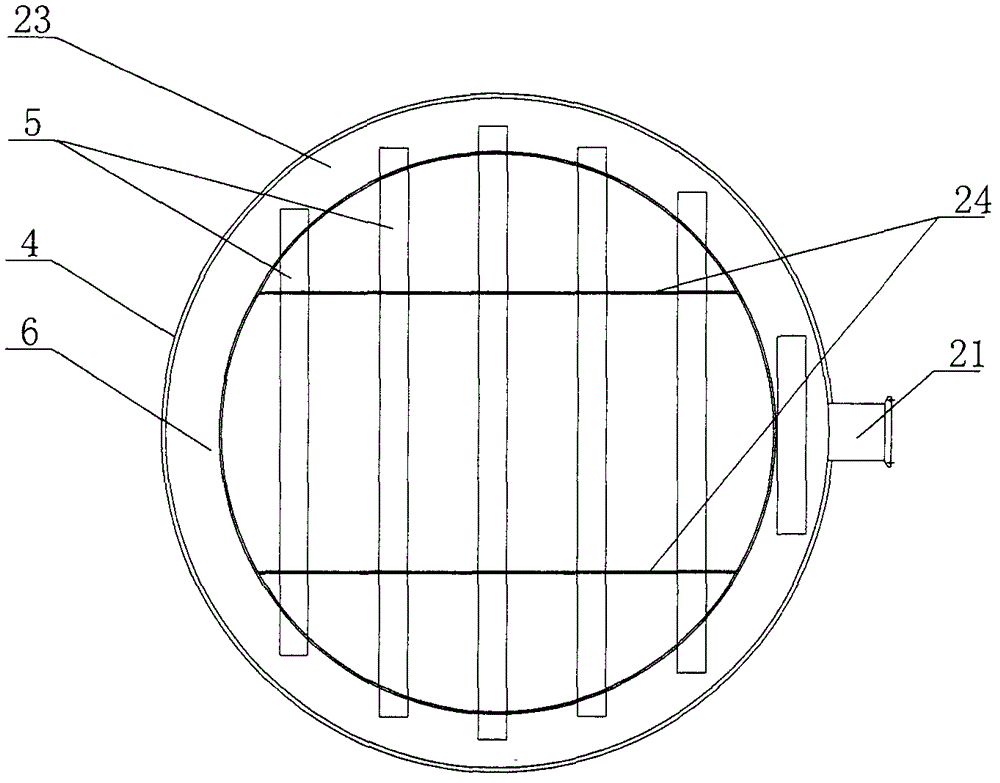

[0010] Such as figure 1 , figure 2 , image 3 As shown, in the above-mentioned embodiment, the liquid collector 7 includes a housing 4, and the housing 4 is provided with a collecting plate 5 and a circular feed liquid pan 6. The collecting plate 5 is L-shaped and distributed obliquely, and the collecting plate 5 is evenly distributed. Spaced and distributed in parallel, the upper part of the collection plate 5 is also L-shaped, the bottom of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap