Continuous mixing method and device for powdery materials

A powdery material and mixing device technology, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of serious material caking inside the conical shell, dead angles and dead spots when mixing materials, and achieve Significant energy saving effect, strong mixing adaptability, and the effect of occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The continuous mixing method of the powdery material in this embodiment is a combined mixing mode of two-stage mechanical agitation to break the agglomerate and one-stage pneumatic homogenization. Combined mixing method is that the materials that enter the mixing device at the same time in proportion are continuously passed through the first-stage mechanical agitation and broken-agglomeration mixing, the second-stage mechanical agitation and broken-agglomerate mixing, and the bottom pneumatic homogenization and mixing from top to bottom according to gravity. Complete the mixing process.

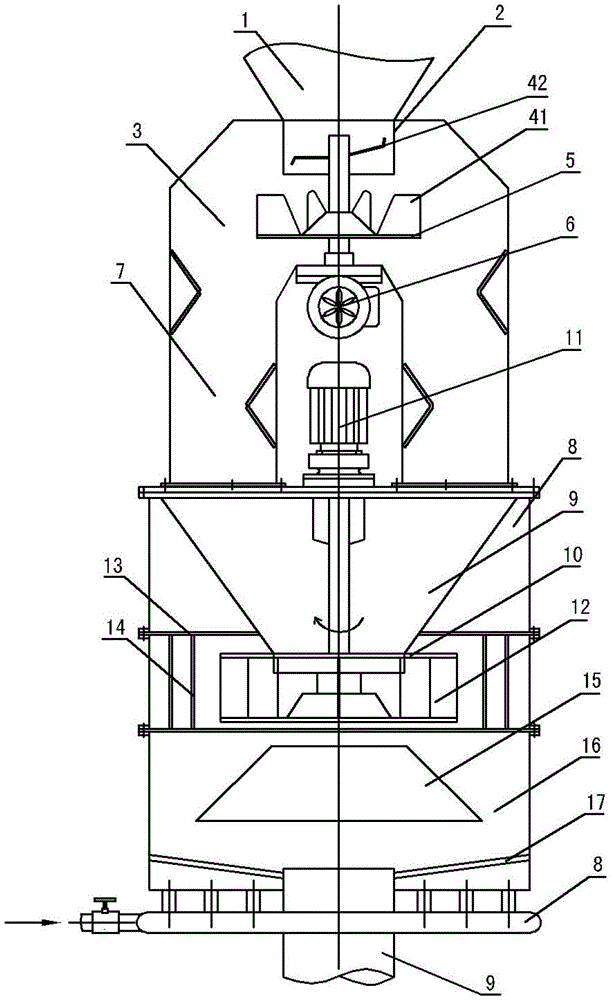

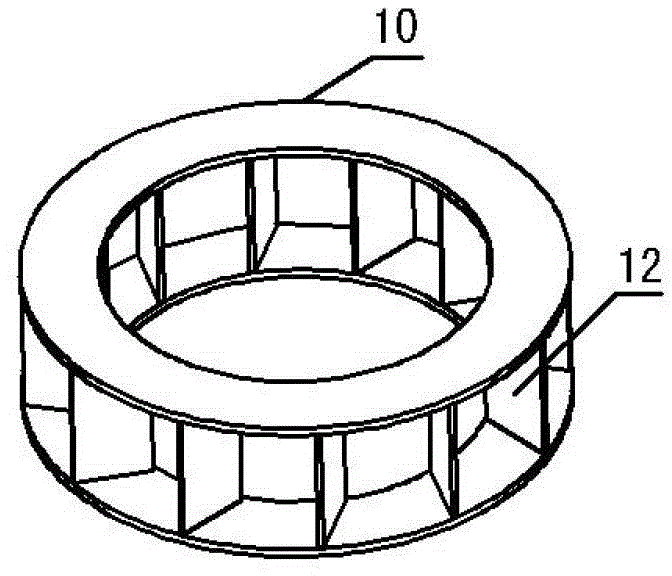

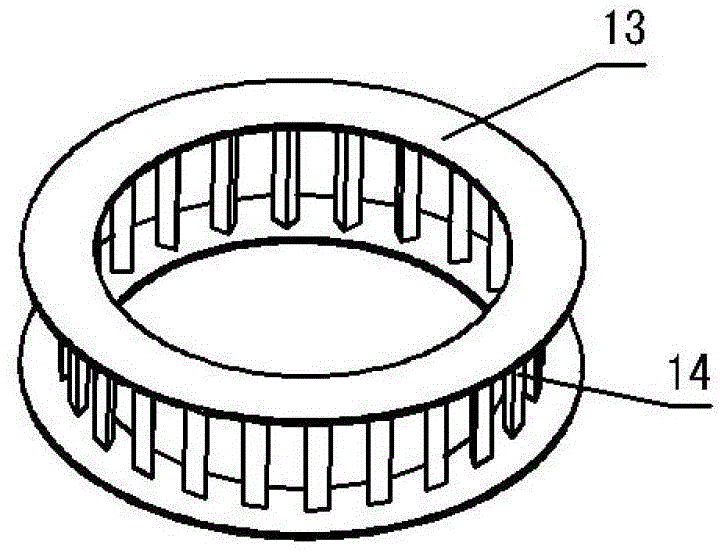

[0019] see figure 1 , figure 2 and image 3 , the structural form of the powdery material continuous mixing device in the present embodiment is:

[0020] The mixing device is set as a vertical structure, and the collecting hopper 1 for feeding two or more powdery materials is set on the top of the mixing device, located below the collecting hopper 1 and in the same center On the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com