Efficient upright ball mill

A ball mill and vertical technology, which is applied in the field of high-efficiency vertical ball mills, can solve the problems of inconvenient work, reduce the working efficiency of the vertical mill, and be difficult to start the next time, and achieve the effect of ensuring the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, describe the best implementation mode of the present invention through preferred embodiment, the specific implementation mode here is to illustrate the present invention in detail, and should not be interpreted as the limitation of the present invention, without departing from the spirit and essence of the present invention Various changes and modifications can be made within the scope of the present invention, and these should be included in the protection scope of the present invention.

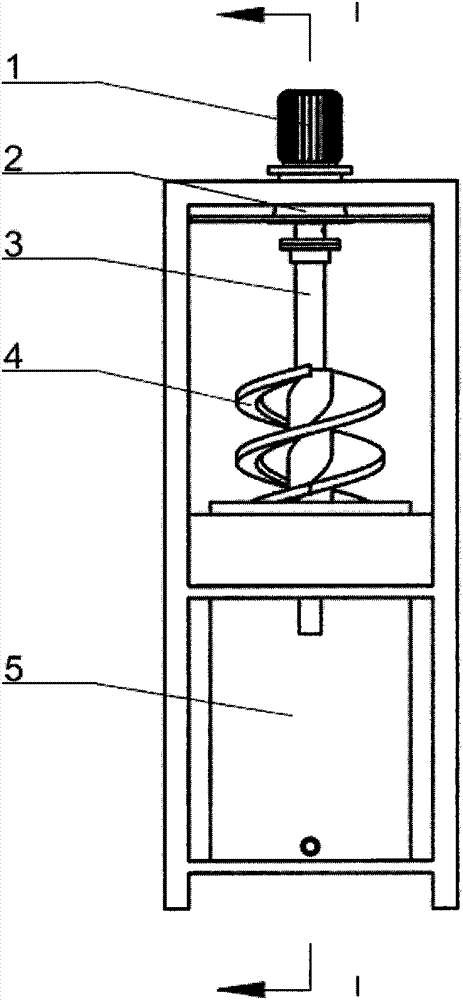

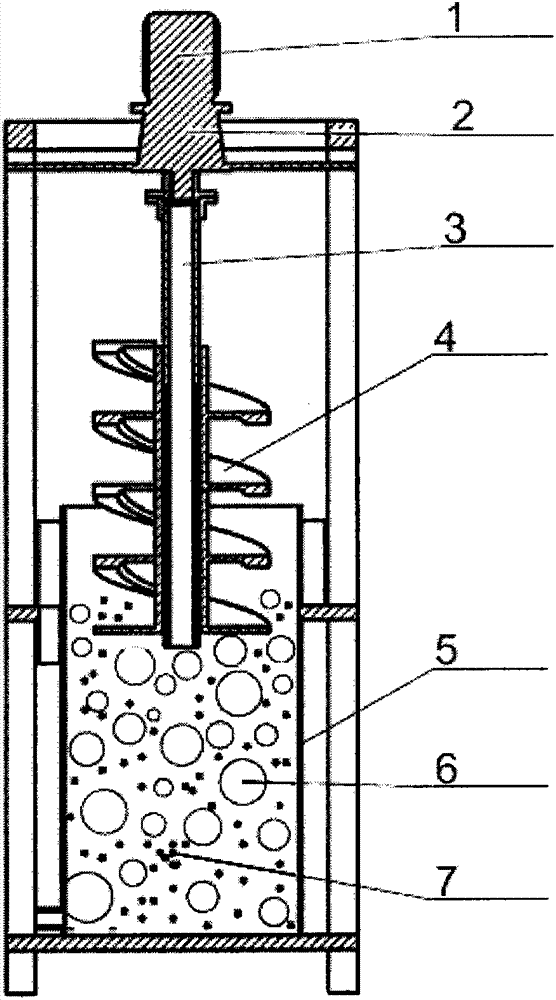

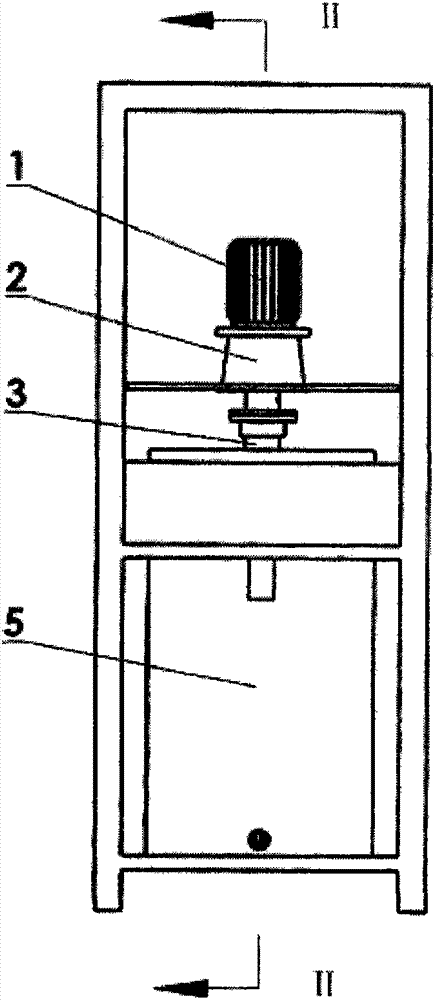

[0025] see figure 1 , which shows a high-efficiency vertical ball mill according to a preferred embodiment of the present invention. The high-efficiency vertical ball mill includes: a shell; a grinding barrel 5, which is fixedly arranged in the shell and located at the middle and lower part of the shell, and the grinding barrel 5 is used to place the grinding balls 6 and abrasive materials 7 to be processed; The ball milling unit of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com