Steering gear box support

A technology of steering machine and support plate, which is applied in the direction of steering control installed on the car, can solve product quality problems, hidden dangers, stress concentration and other problems, and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

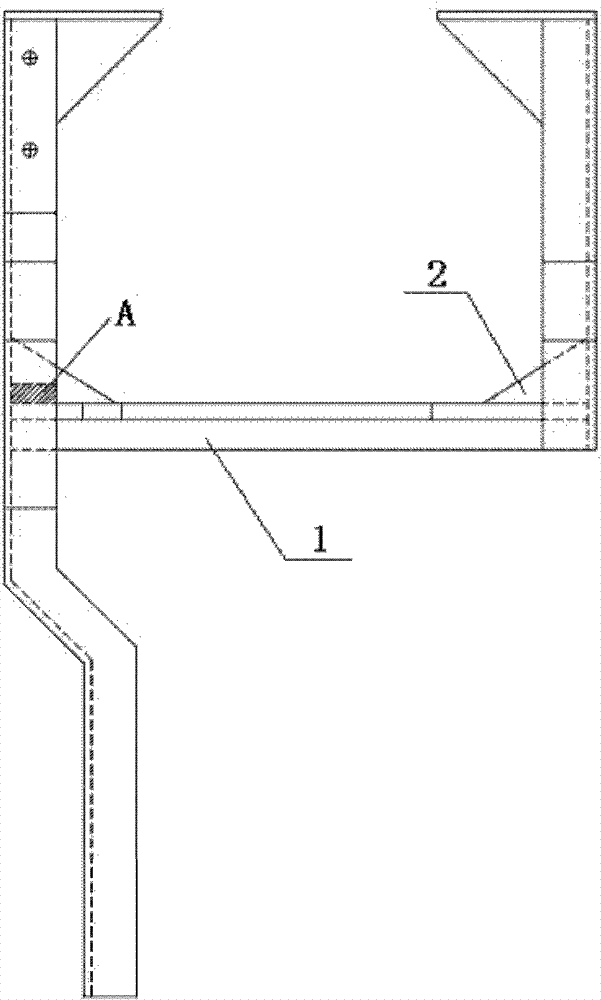

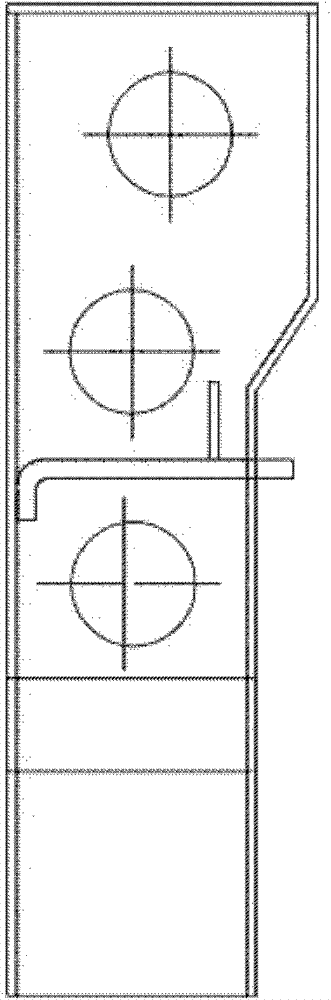

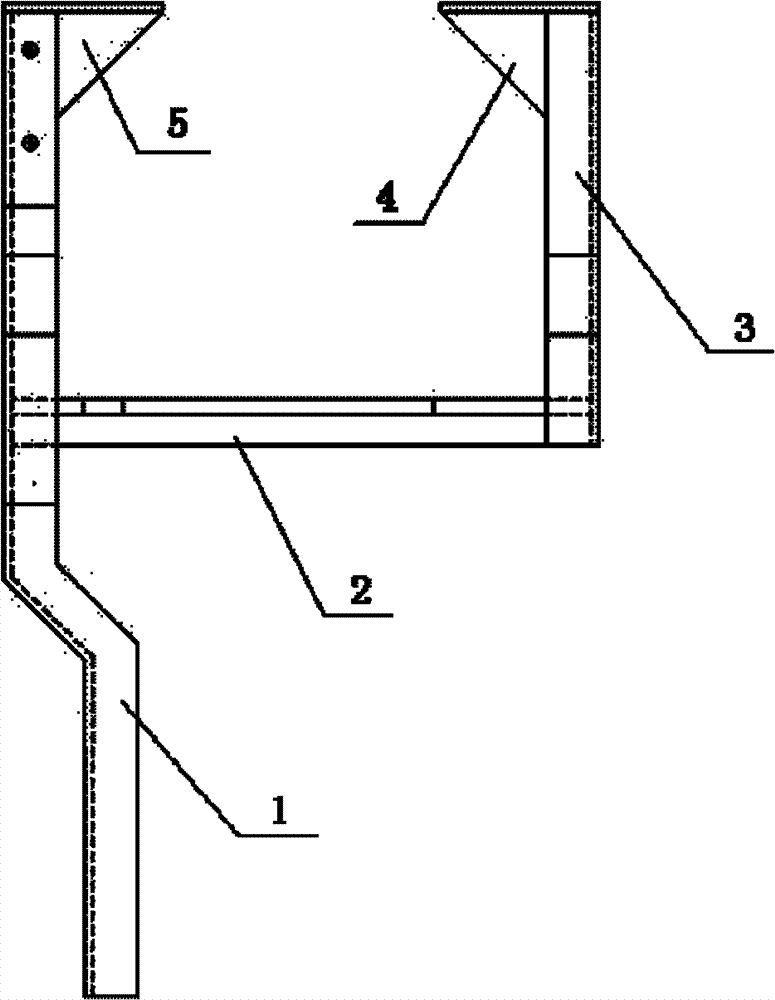

[0014] Such as image 3 , Figure 4 As shown, a steering machine bracket is improved on the traditional bracket, and the reinforcing rib is canceled. After testing, the strength of the steering machine bracket is not affected in any way after the rib is canceled, and the bracket no longer cracks. The phenomenon, and save the material of the rib. The present invention only includes support plate 1, horizontal plate 2, vertical plate 3. One end of the horizontal plate 2 is connected with the middle part of the support plate 1 , and the other end of the horizontal plate 2 is connected with the vertical plate 3 . Three through holes 6 are provided on the support plate 1 . The top of the support plate 1 is provided with a first positioning plate 5 , and the top of the vertical plate 3 is provided with a second positioning plate 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com