Double-sealed sound and heat insulating floor maintenance cover

An inspection cover and double-sealing technology, which is applied to the upper structure, upper structure sub-assembly, transportation and packaging, etc., can solve the problem of heat insulation and noise reduction of the floor inspection opening, the deviation of the inspection opening and the inspection cover, and the manufacturing accuracy Low-level problems, to achieve the effect of improving sealing and sound insulation and heat insulation performance, fine workmanship, and standardized product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

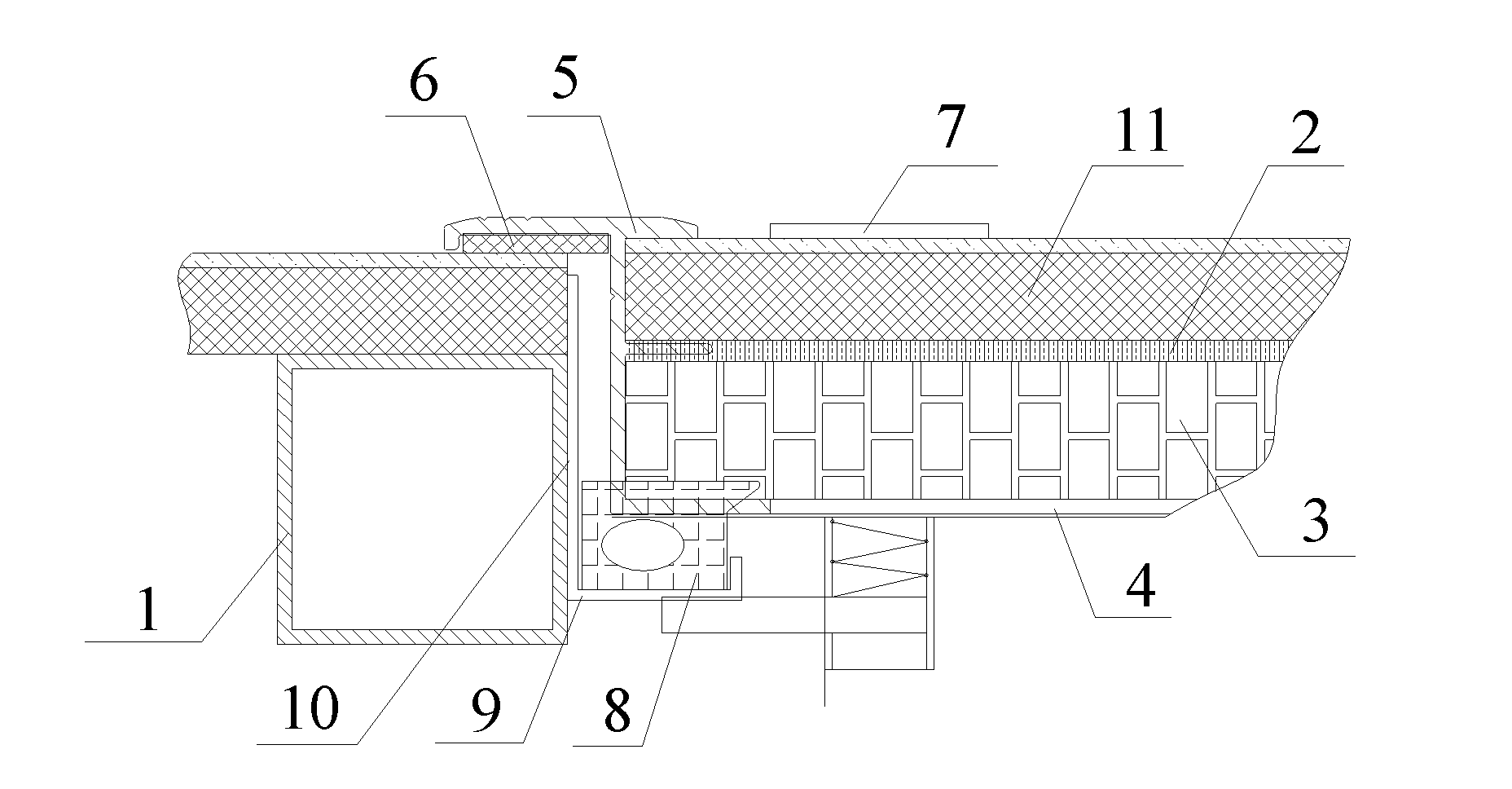

[0017] A double-seal sound-insulation and heat-insulation floor access cover, the structure of which is as follows figure 1 As shown, the inspection cover includes an inspection frame 1, a sound-insulating rubber layer 2, a noise-reducing sponge layer 3, and a perforated aluminum mesh 4. , The sound-insulating rubber layer 2 is arranged on the top, the noise-reducing sponge layer 3 is arranged on the bottom of the sound-insulating rubber layer 2, and the perforated aluminum mesh 4 is arranged on the bottom of the noise-reducing sponge layer 3. An aluminum profile 5 is arranged on the top of the inspection frame 1, and the aluminum profile 5 is affixed to the floor 11 through a single-sided rubber strip 6, and the inspection frame 1 is fixed on the floor 11 through a lock 7. The bottom of punching aluminum mesh 4 is provided with rubber sponge 8, and this rubber sponge 8 is arranged in L-shaped iron sheet frame 9, and this iron sheet frame 9 is connected with the inner frame of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com