Automobile headlamp switch

A technology for automobile headlights and light switches, applied in electrical components, circuits, emergency protection devices, etc., can solve the problems of uncomfortable adjustment switch operation, structural influence on viewing, low integration, etc., to improve product quality. , shorten the processing cycle, the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

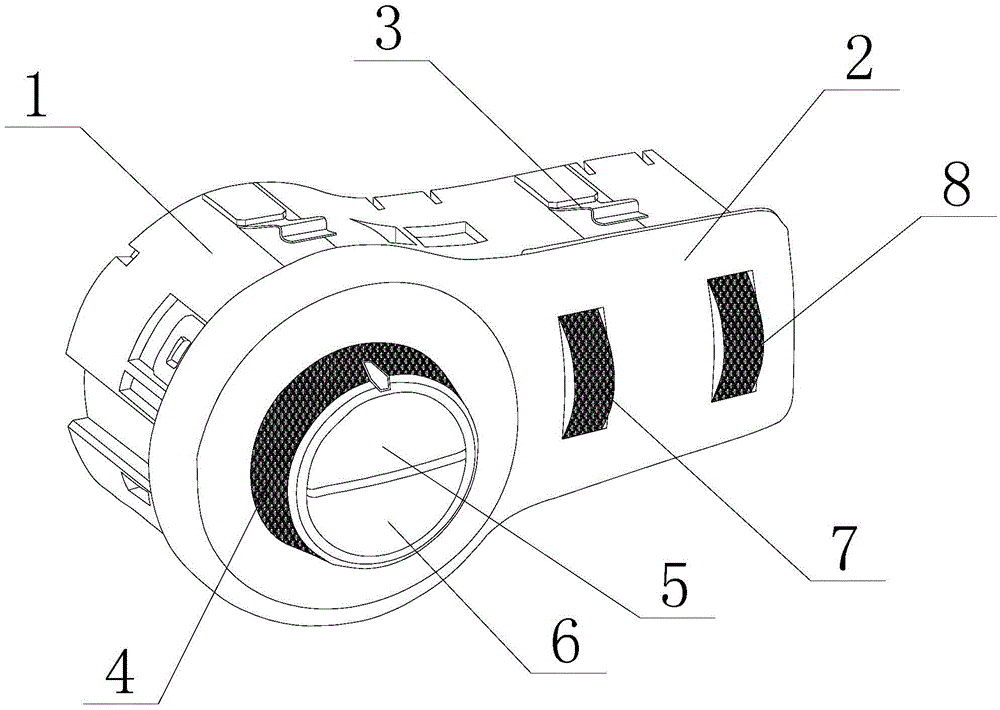

[0023] This embodiment provides an automobile headlight switch, comprising a box body 1, a panel 2 and a circuit control board arranged in the box body, and at least four elastic buckles 3 are arranged symmetrically on both sides of the box body for connecting with the car body. The components are fixedly connected to realize the fixing of the switch on the car body. There is also a light switch assembly and two light adjustment mechanisms in the box body. The light switch installation holes and two light adjustment mechanism installation holes are correspondingly arranged on the panel. The box body It is fixedly connected with the panel by buckle; the light switch assembly is composed of headlight switch 4, front fog light switch 5 and rear fog light switch 6. The headlight switch is a hollow cylindrical adjustment knob, which is in the hollow of the headlight switch The knob is equipped with a front fog light switch button and a rear fog light switch button. The headlight swi...

Embodiment 2

[0029] The structure of this embodiment is the same as that of Embodiment 1, the difference lies in the difference between the materials of the box body and the panel, the box body and the panel of this embodiment are made of high-strength flame-retardant materials, and the high-strength flame-retardant materials are composed of A, The two components of B are mixed and melted in a ratio of 5:3 by weight, and the A component includes: phenolic resin: 48 parts, phthalate plasticizer: 5 parts , phenylene diisooctyl phosphite: 7 parts, methyltriethoxysilane: 11 parts, dimethylolpropionic acid: 11 parts, isophorone diisocyanate: 6 parts, potassium hydroxide: 8 parts, Molybdenum trioxide: 5 parts, flame retardant: 6 parts, triphenyl phosphite: 2 parts, polyester fiber: 16 parts, silane coupling agent KH550: 6 parts, hydroxymethyl aliphatic amine: 4 parts, graphite powder : 9 copies;

[0030] Component B includes: PVDF: 85 parts, silicon carbide: 3 parts, silicon micropowder: 2 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com