Discharging method for electroplated electronic components

A technology for electronic components and driving motors, which is applied in the field of discharging of electronic components after electroplating, can solve the problems of easily damaged drums, high labor intensity, time-consuming and other problems, and achieves the effects of high efficiency, convenient operation and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

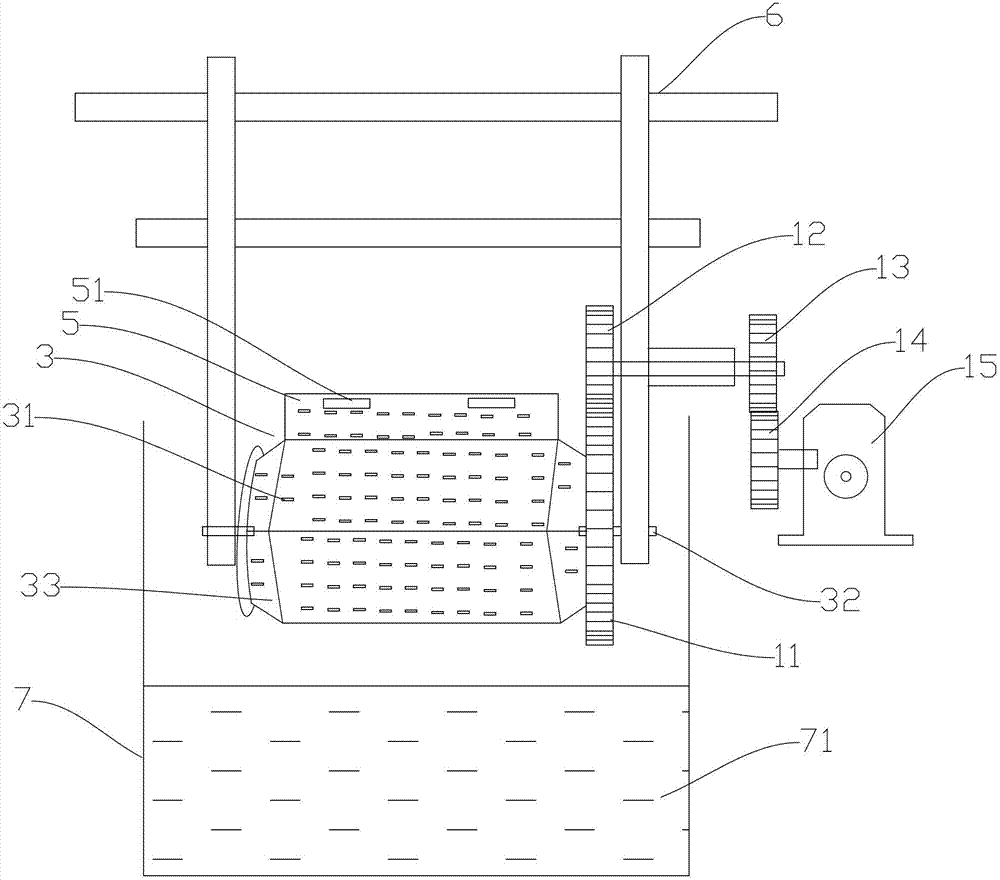

[0022] like figure 1 As shown, the drum device used in the present invention includes a drum 3 , and the drum 3 includes a drum body 33 . An opening (not shown in the figure) is provided on the body of the drum 33 . The drum body 33 is hinged with a top cover 34 that can close the opening. A through hole 31 is provided on the cylinder wall of the drum body 33 . The drum 3 is rotatably arranged on the bracket 6 through the shaft 32 . The drum 3 is provided with a top cover 5, the top cover 5 is provided with a knob 4, and the drum body is provided with a groove matching the knob 4 (not shown in the figure).

[0023] A knob 51 is provided on the top cover 5 . The drum body 33 is provided with a card slot (not shown) matching the knob 51 . The knob 51 cooperates with the slot to connect the top cover 5 with the drum body 33 . The way of cooperation between the knob 51 and the slot can be realized by using the existing technology, which will not be repeated here.

[0024] T...

Embodiment 2

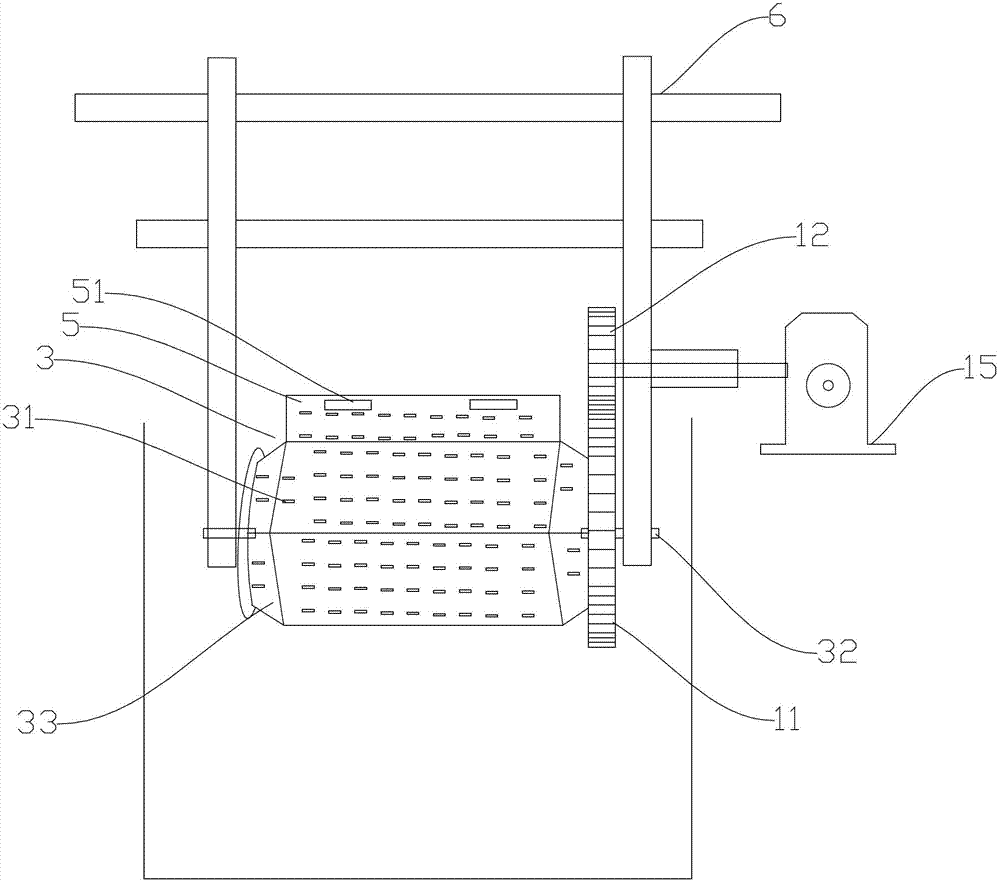

[0027] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the second gear 12 and the third gear 13 in Embodiment 1 are not provided in this embodiment. The first gear 11 meshes with the fourth gear 14 .

Embodiment 3

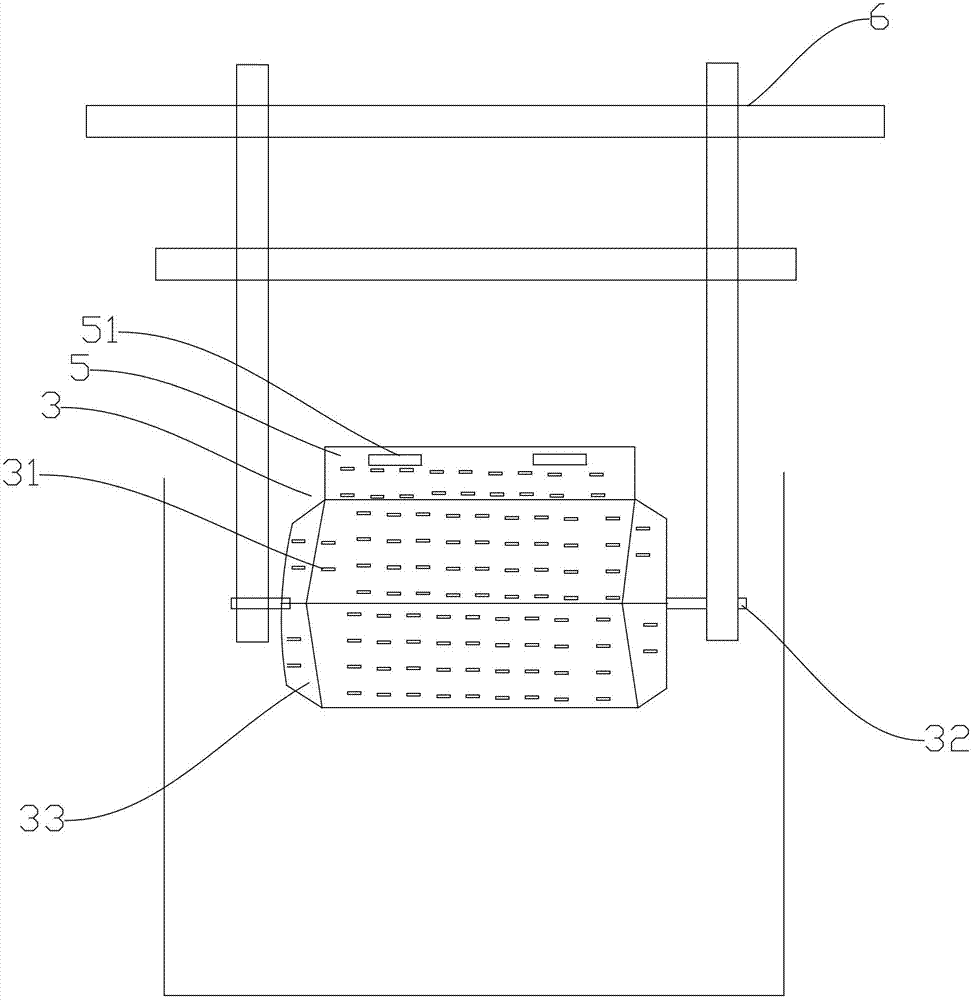

[0029] like image 3 As shown, the difference from Embodiment 1 is that the driving motor 15 and the transmission device are not provided in this embodiment. In this embodiment, the drum 3 is manually rotated by the operator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com