Feeder channel for diluting fluid

A feeder and fluid technology, applied in the direction of textiles and papermaking, paper machine, paper machine wet end, etc., can solve the problem that the channel that cannot be accurately and reliably adjusted by the diluted fluid, cannot be adjusted accurately, and the channel cannot be blocked, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

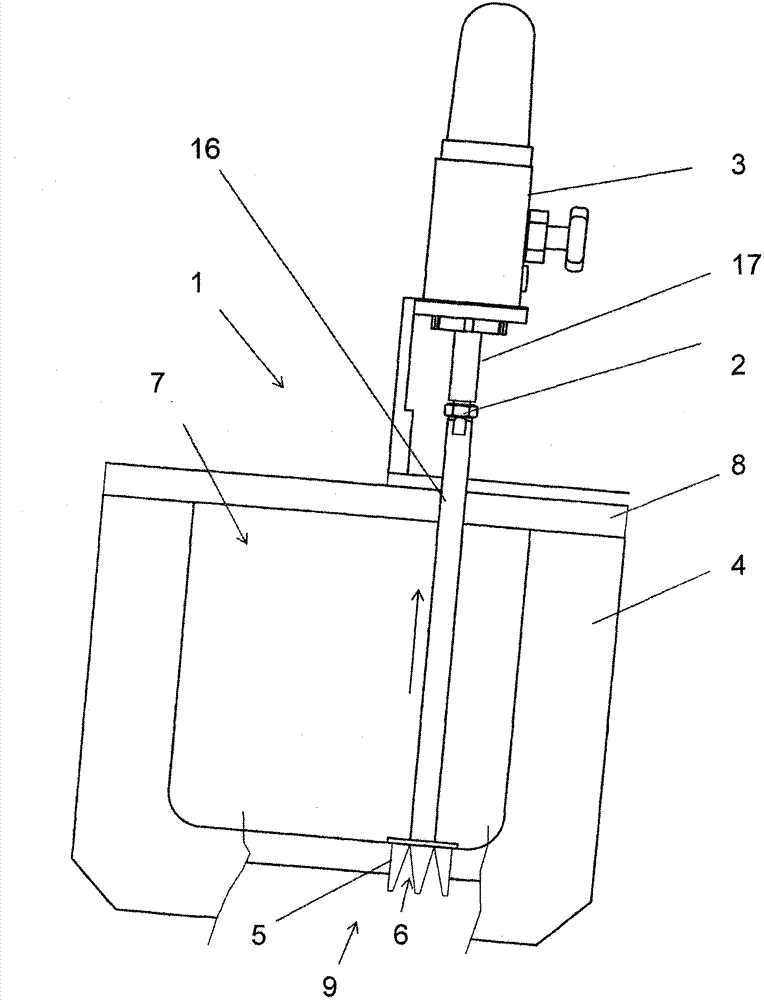

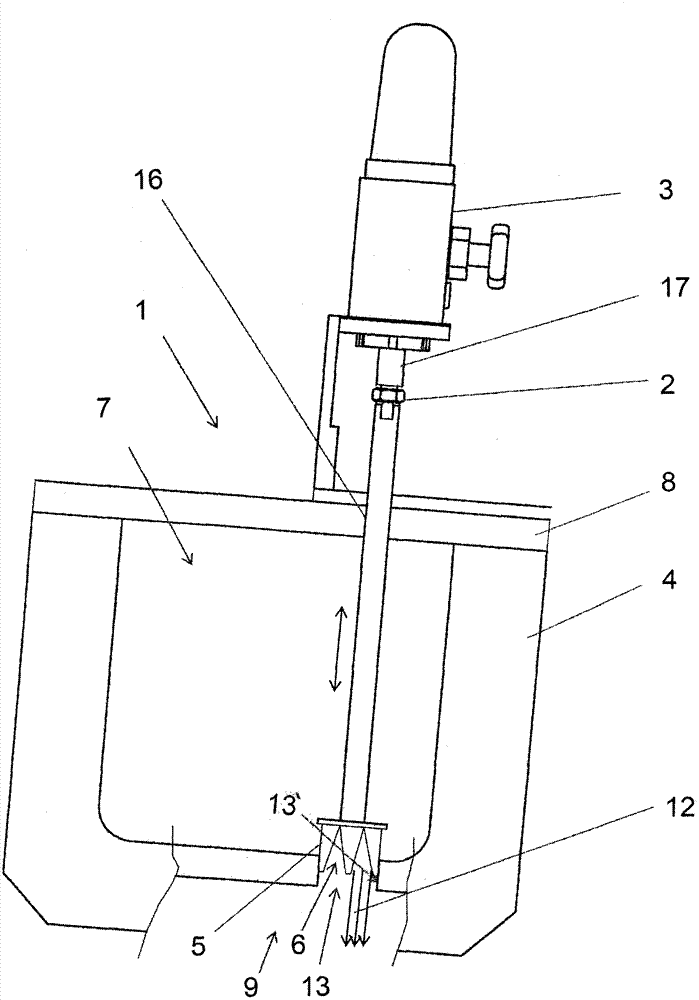

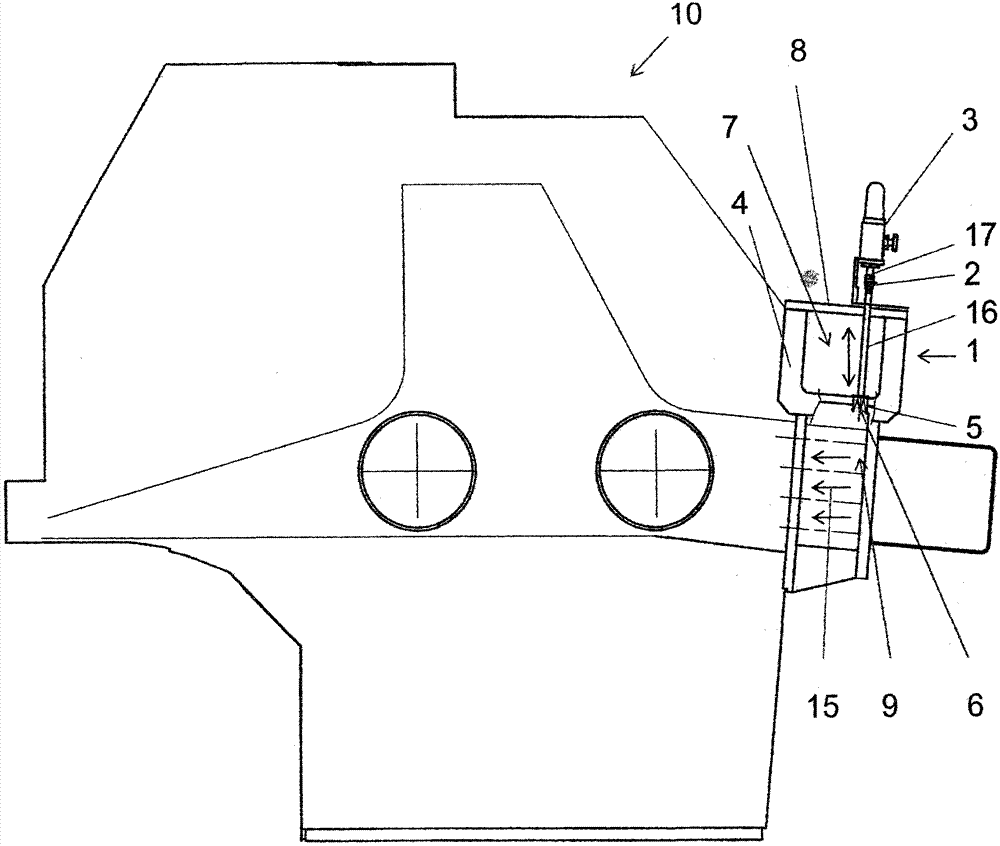

[0020] The feeder channel 1 according to the invention for a dilution fluid, for example for dilution water, consists of Figure 1a and Figure 1b Presentation, the feeder channel is connected with the head box 10 of the paper machine (the head box 10 is presented in Figure 1c and Figure 1d Middle), the feeder channel 1 comprises one or more reservoir-type spaces 7, eg chambers for receiving a dilution fluid such as water, and one or more walls 4, 8 form the spaces 7. A hole 13 is formed in the reservoir type space 7, through which hole dilution fluid can be led into the slurry flow space 9 of the headbox. The flow space 9 comprises a plurality of individual flow channels, such as pipes, i.e. the flow space 9 is usually not an open flow space, but flow space types comprising only one flow channel are also conceivable (the flow space 9 is not shown in the figure for more details).

[0021] One or more cut-off / regulating devices 5 are fitted in said feeder channel 1, presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com