HL type high-strain pile-trialing method hammering system

A pile test method and high-strain technology, which is applied in the testing of foundation structures, construction, infrastructure engineering, etc., can solve the problems of unreasonable guiding devices without guide devices, unreasonable decoupling devices, etc., and achieves good consistency and thickness. Adjustable and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

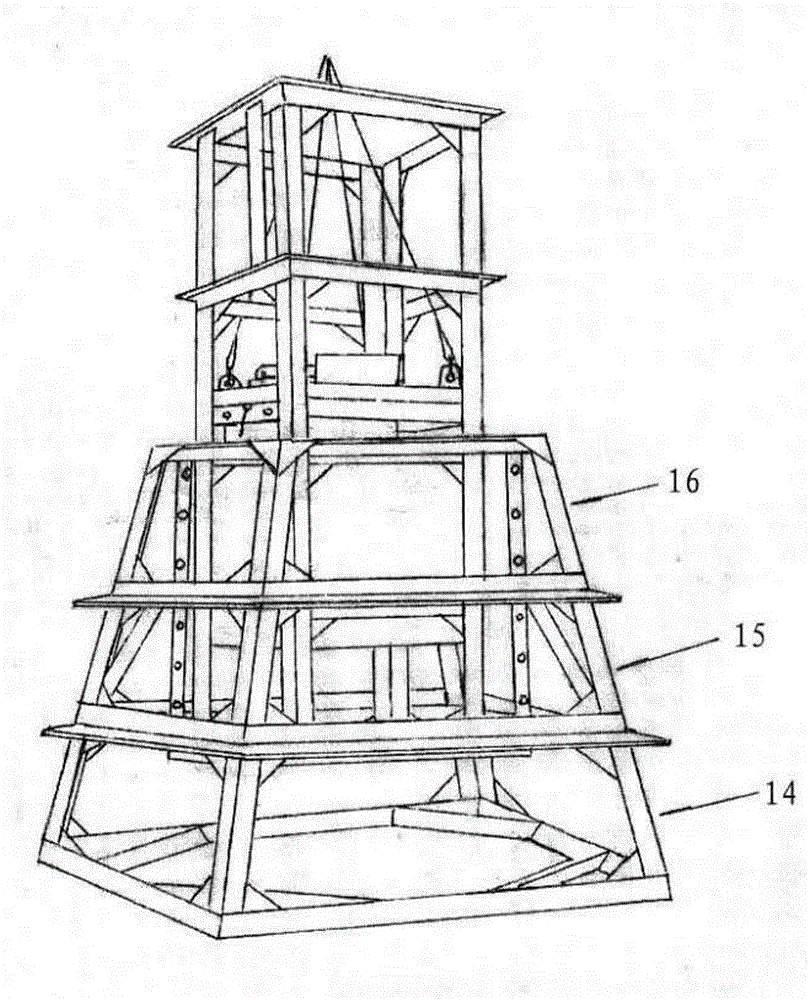

[0050] see Figure 1 to Figure 7 , the embodiment of the invention is described in detail as follows:

[0051] A HL-type high-strain test pile method hammering system is characterized in that it includes from top to bottom:

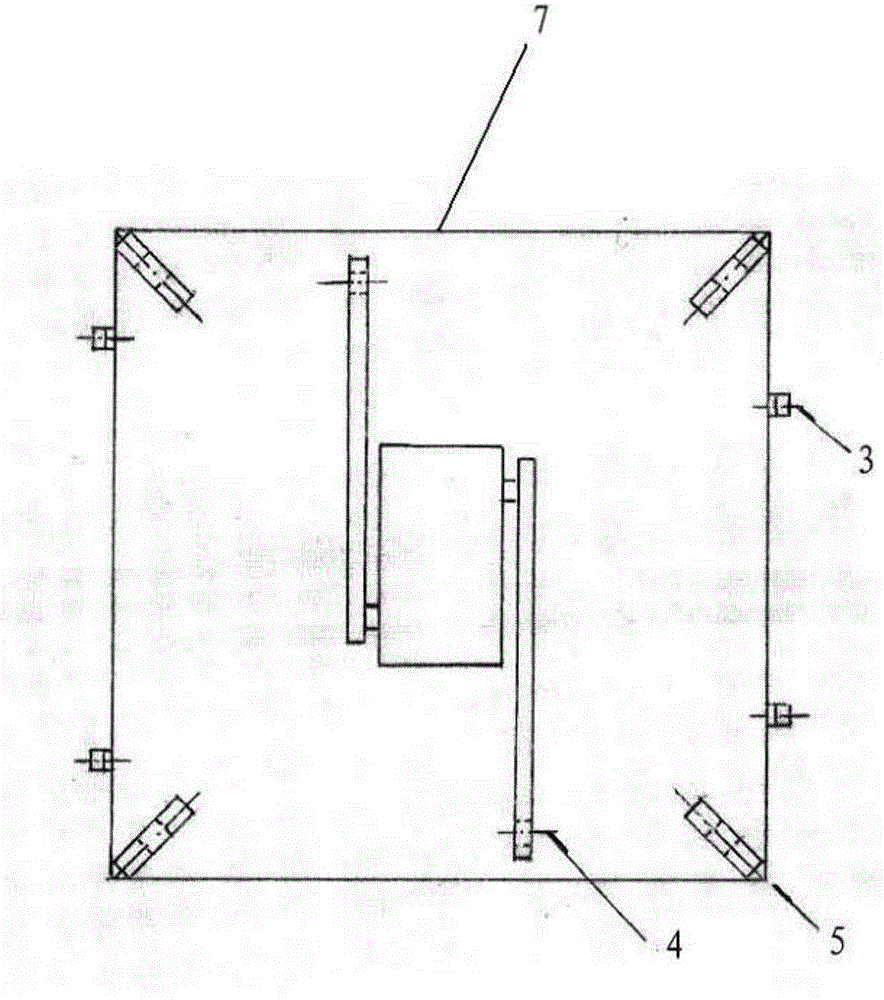

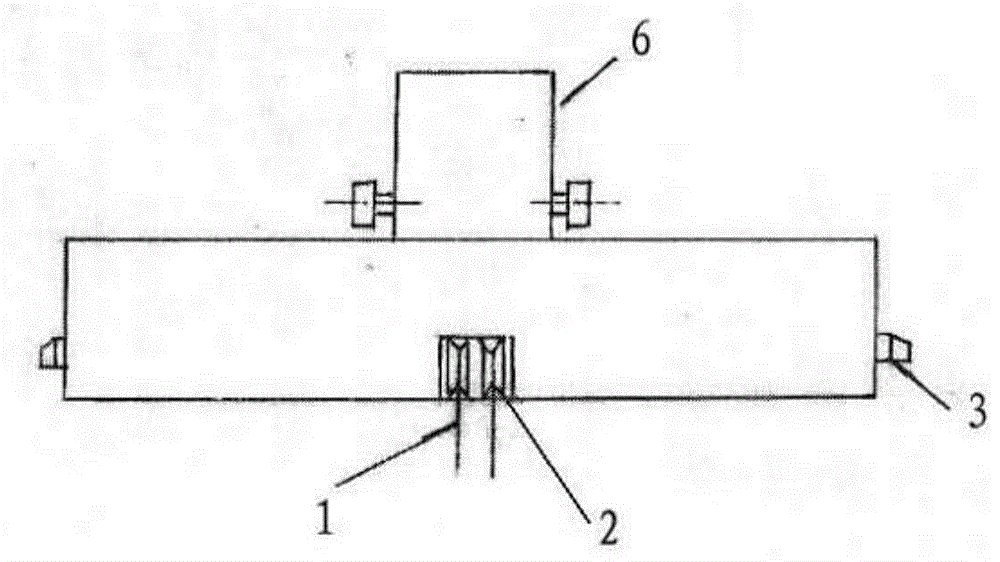

[0052]Lock disc type uncoupling device, weight and retractable guide frame, wherein the outside of the locking disc type decoupling device is a box body 7, and a lock disc 8 is arranged inside the box body 7, and the lock disc 8 is a flat square shell. The surface is provided with a hollow positioning hole lock catch 6, and the outer sides of the lock catch 6 are respectively provided with a parallel lock arm 4. Two telescopic rods 3 are respectively installed on the two long sides of the lock plate 8, and the lower part of one of the short sides of the two short sides A spring 10 is installed, and the spring 10 is connected to the telescopic rod control rope 1 and the telescopic rod lock 2, and the four corners on the upper surface of the lock plate 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com