Tunnel shotcrete non-dismantling formwork and construction method thereof

A technology of sprayed concrete and free formwork, which is applied in earthwork drilling, tunnels, tunnel linings, etc., can solve the problems of difficulty in fixing shotcrete formwork, long formwork period, and slow construction progress, and reduce construction personnel and equipment investment , high-quality and rapid construction, and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

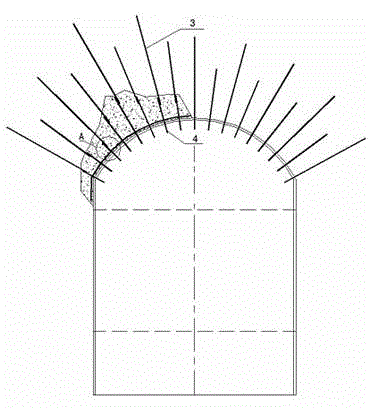

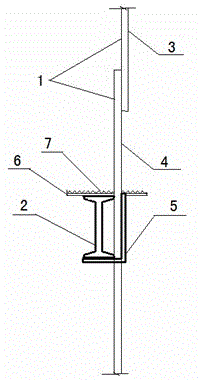

[0024] Such as figure 1 with 2 As shown, the tunnel shotcrete free formwork includes anchor 1 and section steel support 2. Anchor 1 is the system anchor 3 and an extension anchor 4 set according to requirements. The extension anchor 4 is fixedly connected with section steel support 2, and section steel support 2 An L-shaped reinforcing steel bar 5 is set at the connecting part with the extended anchor rod 4, the long arm of the reinforced steel bar 5 is attached to the extended anchor rod 4, the short arm is attached to the bottom surface of the profiled steel support 2, and the reinforcement mesh 6 is arranged on the profiled steel support 2 On the side by the rock face, the steel mesh 6 outside lays fast and easy closing net 7.

[0025] The construction method is:

[0026] ①Use part of the tunnel system anchor rods or directly set the locking foot anchor rods and install the steel support, and effectively weld the part of the system anchor rods and the steel support firmly...

Embodiment 2

[0032] The shotcrete free formwork for tunnels includes anchor 1 and section steel support 2, anchor 1 is system anchor 3, system anchor 3 is fixedly connected with section steel support 2, and the connection between section steel support 2 and system anchor 3 is L-shaped. Reinforcing steel bar 5, the long arm of reinforcing steel bar 5 is attached to the system anchor rod 3, the short arm is attached to the bottom surface of profiled steel support 2, the reinforcement mesh 6 is arranged on the side of profiled steel support 2 close to the rock face, and the outside of reinforcement mesh 6 Lay quick and easy closing net 7.

[0033] The construction method is:

[0034] ①Use part of the tunnel system anchor rods or directly set the locking foot anchor rods and install the steel support, and effectively weld the part of the system anchor rods and the steel support firmly (single-side welding shall not be less than 10d);

[0035] ②Weld φ6.530×30cm steel mesh on the rock face side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com