Floor drain

A floor drain and rotor sleeve technology, which is applied in the field of drainage floor drains, can solve the problems of unfavorable service life of blade generators, poor power generation efficiency and effect, and large vibration of blades, etc., and achieve the effects of reduced impact, high utilization rate, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

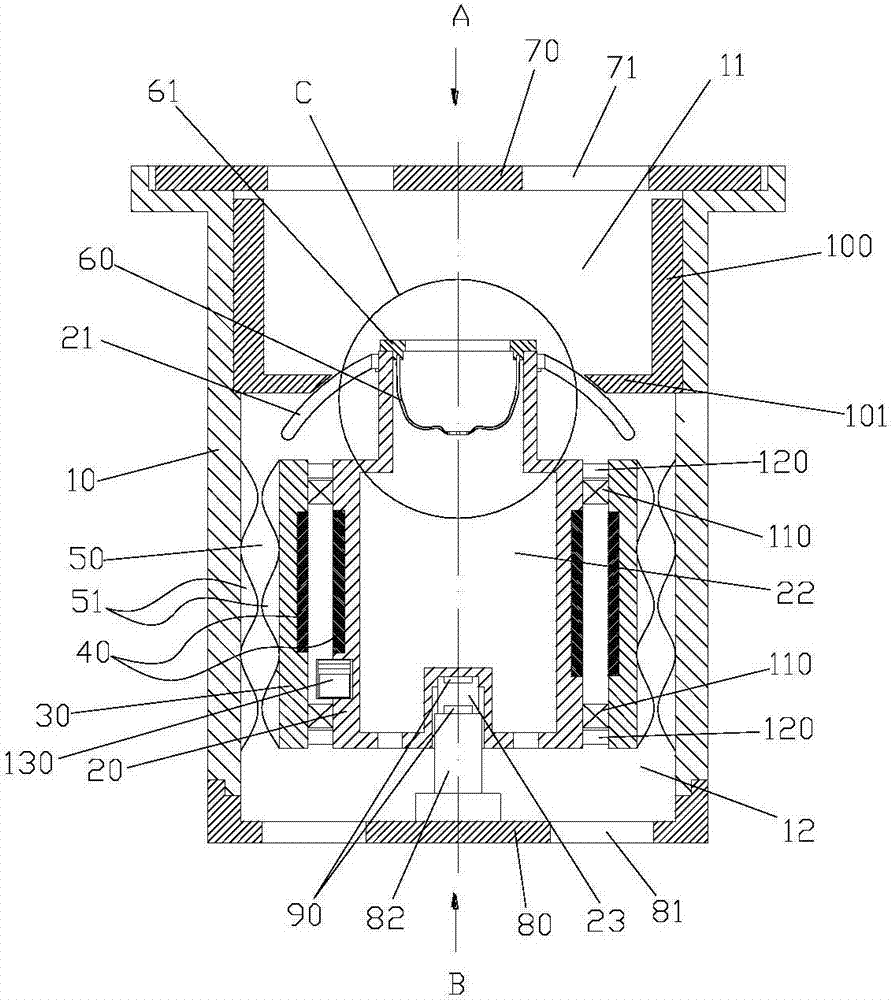

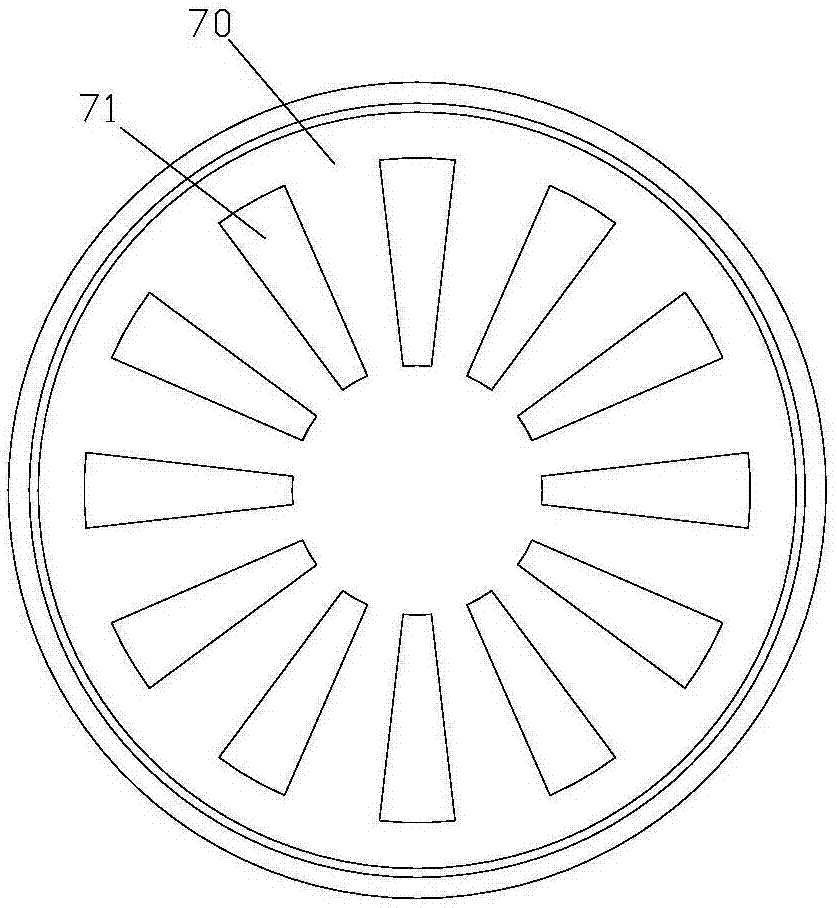

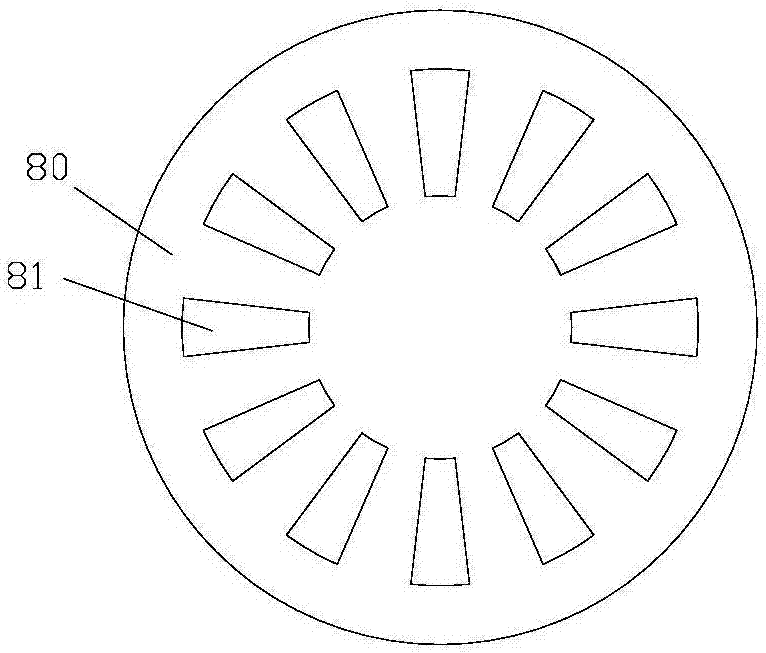

[0038] Such as figure 1 As shown, the embodiment of the present invention discloses a floor drain, which can be installed on the ground that needs drainage, such as bathrooms. The floor drain includes a main body 10 , a stator core 20 , a rotor sleeve 30 and a battery 130 . The main body 10 is formed with a cavity with an open upper end and a drainpipe at the lower end. Water enters the cavity from the upper end of the main body 10 and is discharged from the lower end of the main body 10, and then enters the drainpipe; the stator core 20 is set in such a way that its rotation is restricted In the cavity; the rotor sleeve 30 is set on the stator core 20, and the bearing 110 and the sealing ring 120 are installed between the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com