Lifting rod-type ball valve

A technology for lifting rods and ball valves, which is applied to valve details, valve devices, valve housing structures, etc., can solve problems such as pipeline downtime maintenance economic losses, packing sealing material wear, and increased personnel maintenance processes, so as to save maintenance time and cost, Efficient sealing and reduced frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

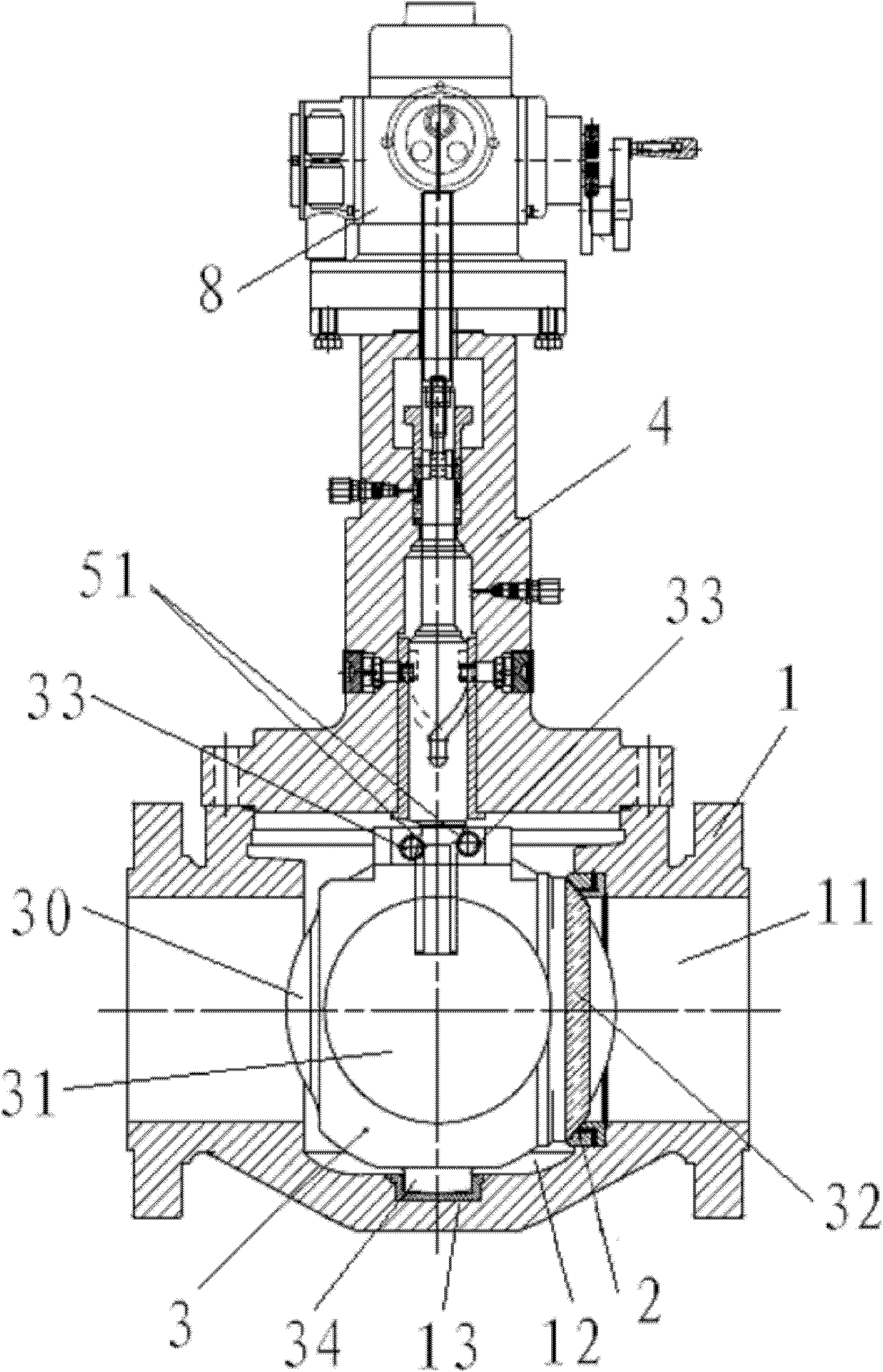

[0029] see Figure 1 to Figure 4 , The lifting rod ball valve of the present invention includes a valve body 1, a valve seat 2, a ball 3, a valve cover 4, a valve stem 5, two sets of sealing packing 6, a packing gland 7 and an actuator 8.

[0030] A coaxial fluid passage is provided at the center of the valve body 1 and the valve seat 2 .

[0031] The valve seat 2 is arranged in the inner cavity of the valve body 1 and divides the fluid channel of the valve body 1 into a fluid chamber 11 and a valve chamber 12 by means of a ball 3 .

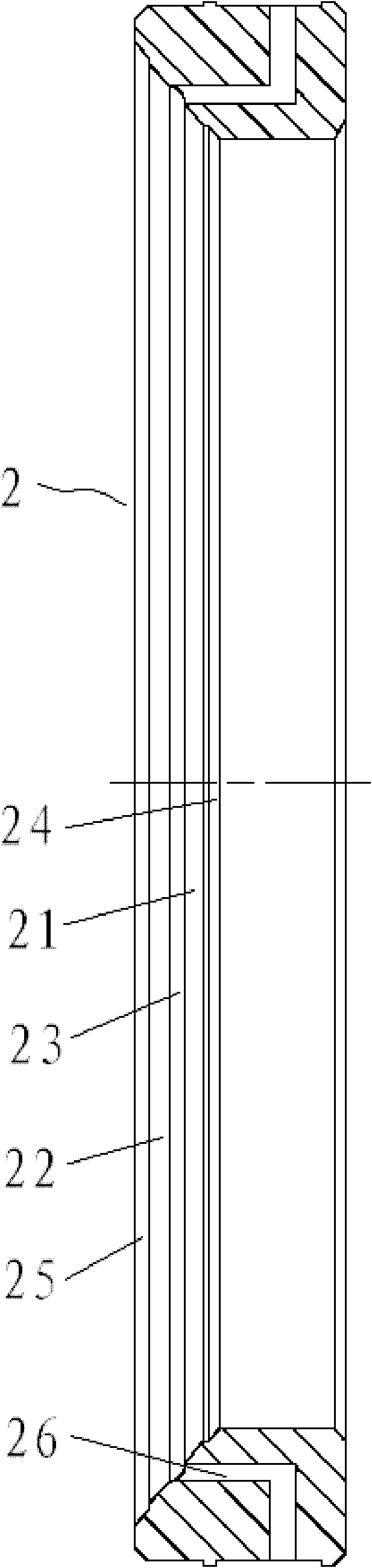

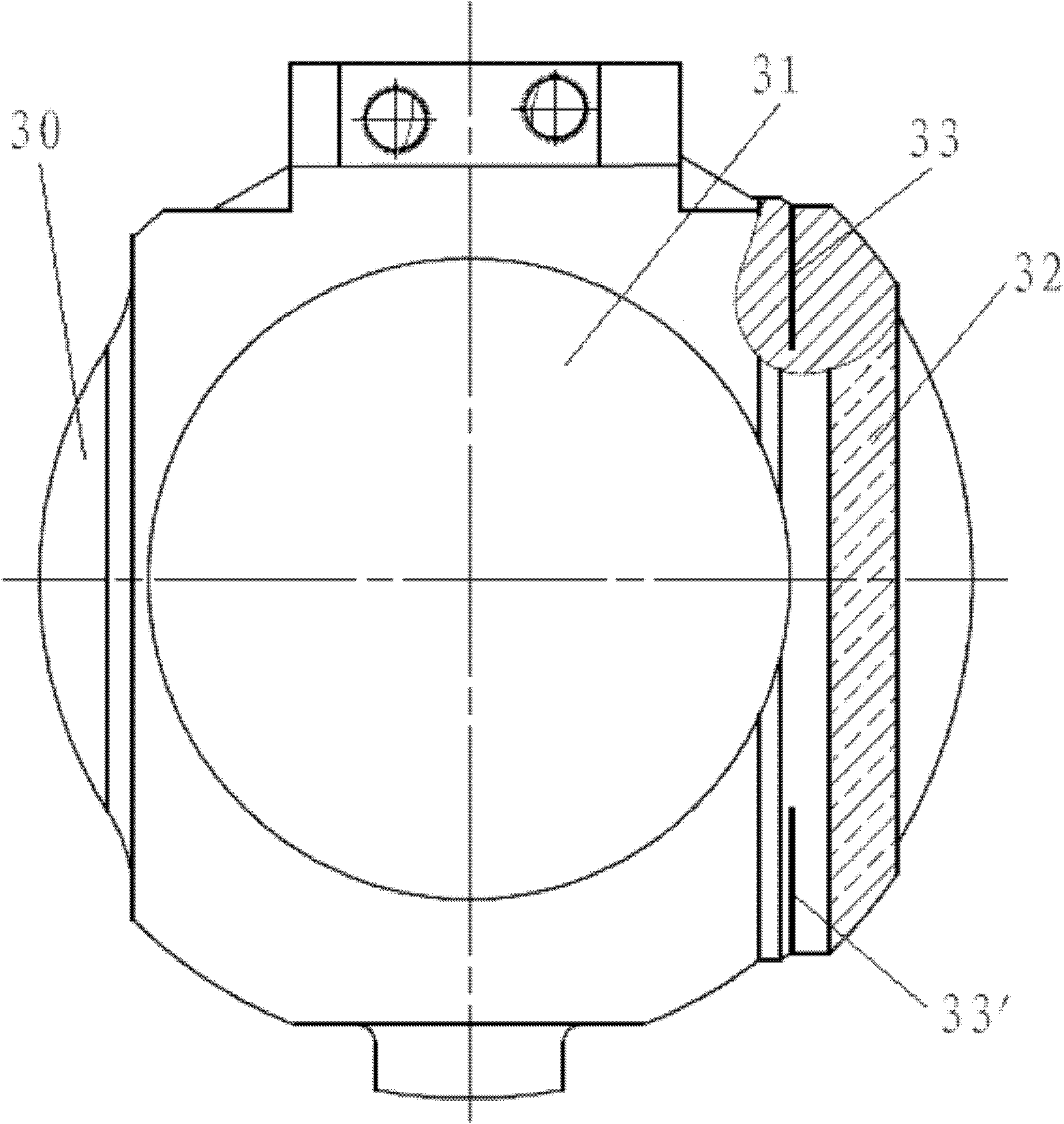

[0032] The ball 3 is movably arranged in the valve chamber 12. The ball 3 includes a ball body 30 provided with a central passage 31 and a spherical sealing ring 32. The spherical sealing ring 32 is concentrically fixed on the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com