Method for manufacturing flexible display substrate

A flexible display and manufacturing method technology, applied in nonlinear optics, semiconductor/solid-state device manufacturing, optics, etc., can solve problems such as uneven surface, uneven device characteristics, and inability to recover plastic deformation of flexible display substrates, so as to avoid plastic deformation. Deformation, the effect of ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

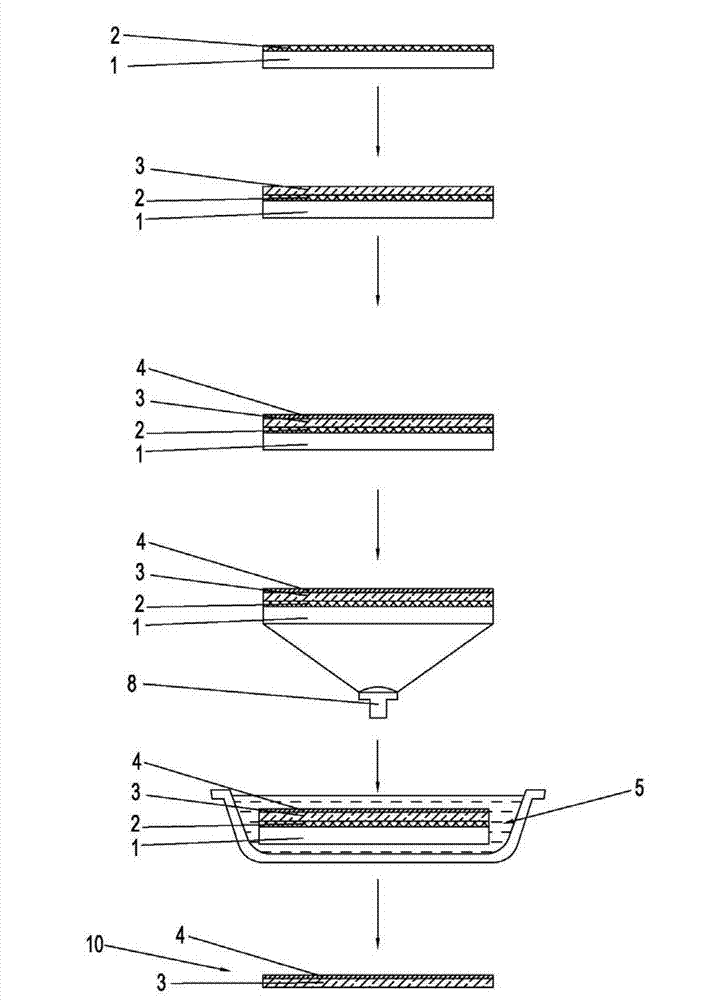

[0027] The embodiment of the invention discloses a method for manufacturing a flexible display substrate. The manufacturing method of the flexible display substrate according to the embodiment of the present invention firstly prepares a base layer on the carrier substrate, prepares a flexible base substrate on the base layer, and then removes the base layer to obtain a flexible display substrate. Because the back of the flexible substrate is only in contact with the base layer and not with the carrier substrate, there will be no air bubbles to damage the back of the flexible substrate, thereby ensuring the precise fixing of the position of the flexible substrate and the flexible substrate. Under the premise of ensuring the flatness of the base substrate, plastic deformation of the flexible display substrate is avoided.

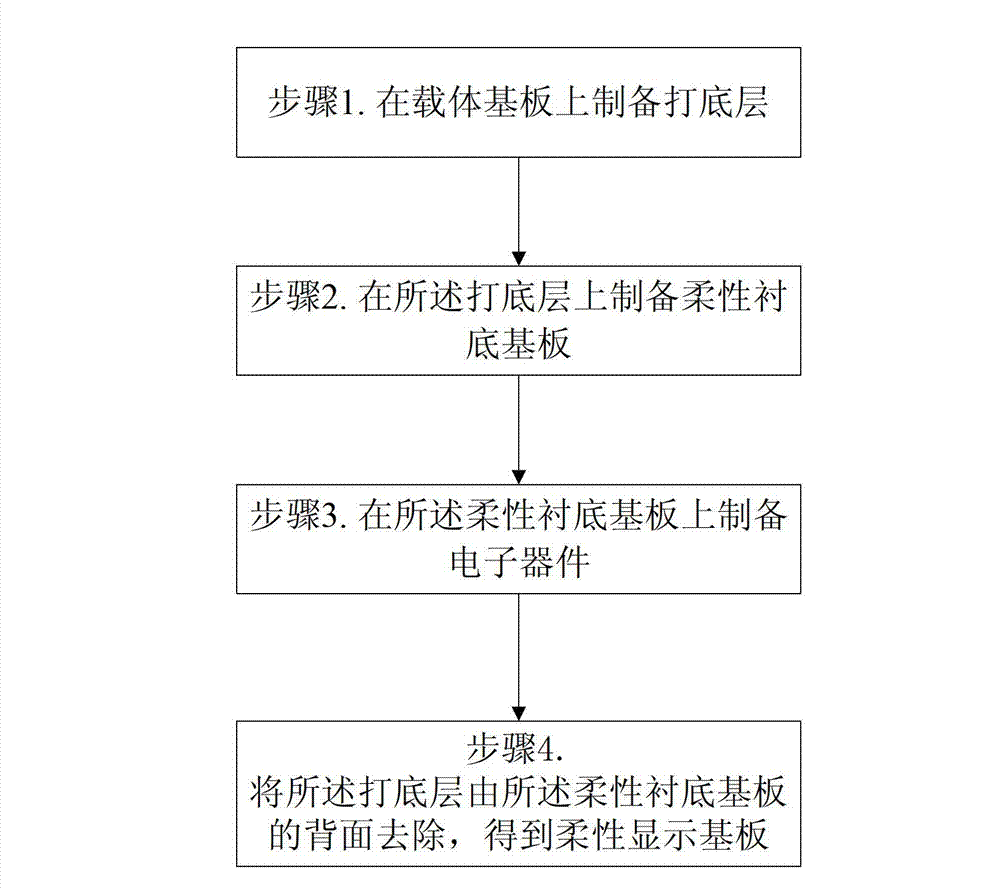

[0028] Such as figure 1 As shown, the manufacturing method of the flexible display substrate according to the embodiment of the present invention includes: ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap