Special system for braze joint between radiator and collector of STWT (Spatial Travelling Wave Tube)

A special system and traveling wave tube technology, which is applied in the field of special systems for brazing connection between radiation radiators and collectors of space traveling wave tubes, can solve the problems of insulation performance decline, aging deterioration, device damage, etc., and achieve low thermal resistance of welding seams. , to avoid aging and deterioration, to avoid the effect of large changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

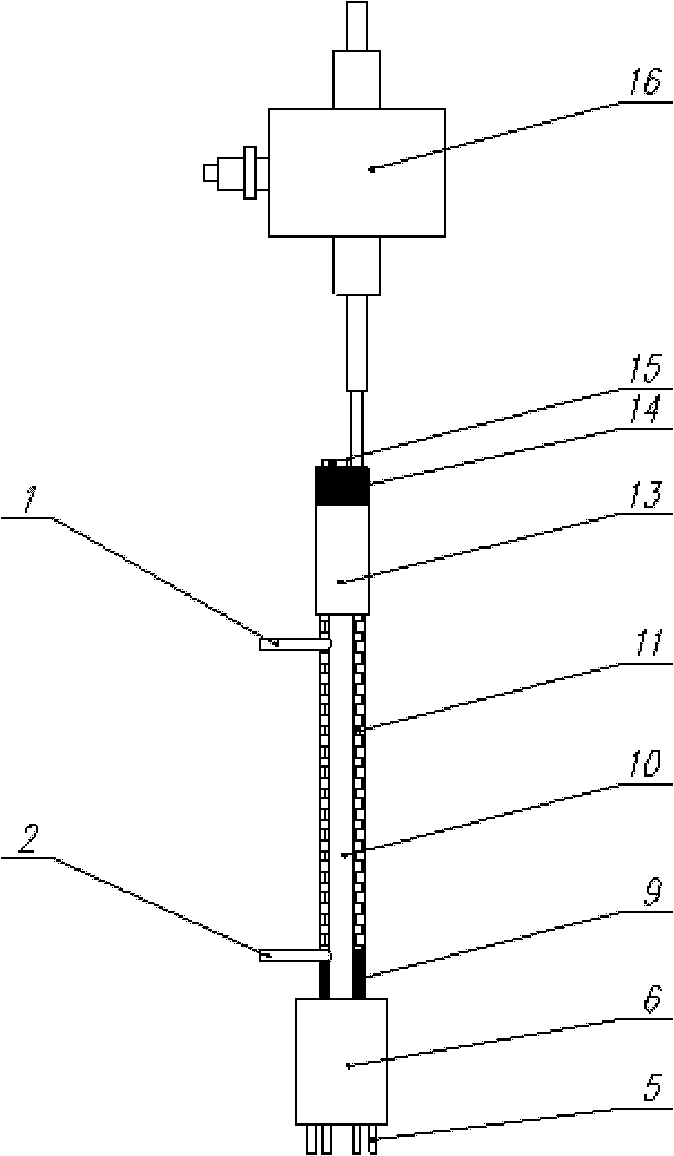

[0031] The overall structure of the space traveling wave tube before brazing the radiant radiator, see figure 2 .

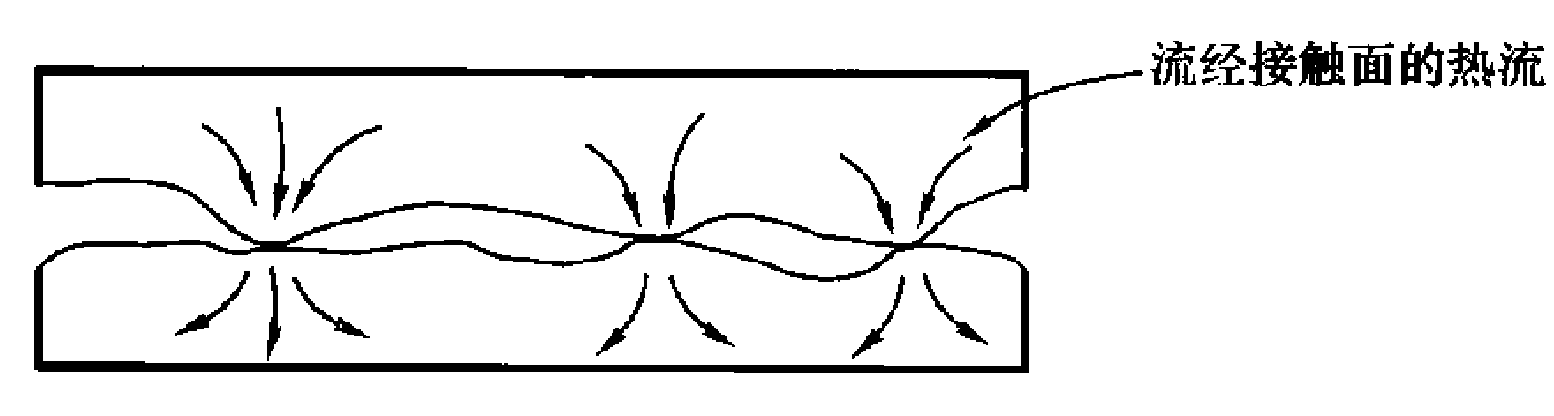

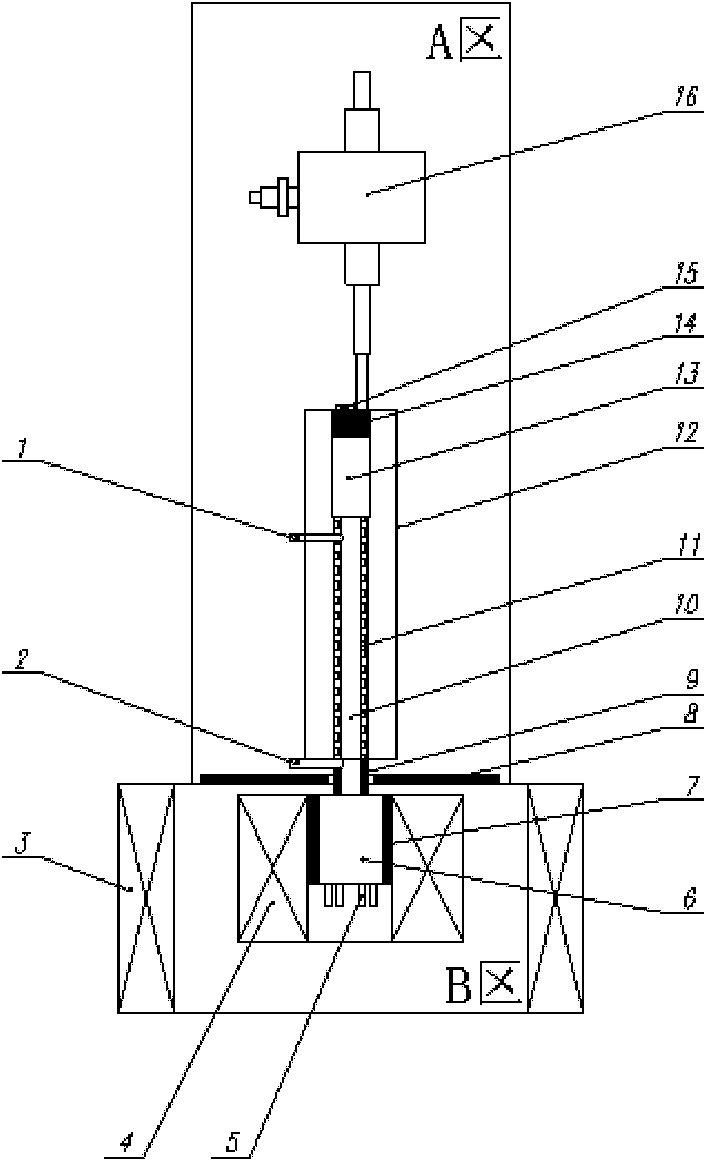

[0032] Such as image 3 Shown is a dedicated system of brazed connections between the radiant radiator of the present invention and the collector of a space traveling wave tube. The heat insulation device 8 divides the entire vacuum cavity into two cylindrical areas, A and B, the upper and lower cylindrical areas. The A area is a vacuum area without a heating device, and the B area is a vacuum area with a heating device. The brazed connection between the radiation radiator 4 and the space traveling wave tube collector 6 is in zone B, and the rest of the traveling wave tube is in zone A. When working, the vacuum degree of the two areas of A and B is ≤1.2×10 -3 Pa, the low vacuum is beneficial to get rid of the gas in the solder 7 during the brazing process, realize the full filling of the solder between the radiation radiator and the collector of the space tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com