Combined mold for plane window frame

A combined mold and window frame technology, which is applied in the direction of manufacturing tools, forging/pressing/hammering machinery, forging/pressing/hammering devices, etc., can solve problems such as easy deformation and difficulty of forging webs and ribs, and difficulties in mold manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with example accompanying drawing.

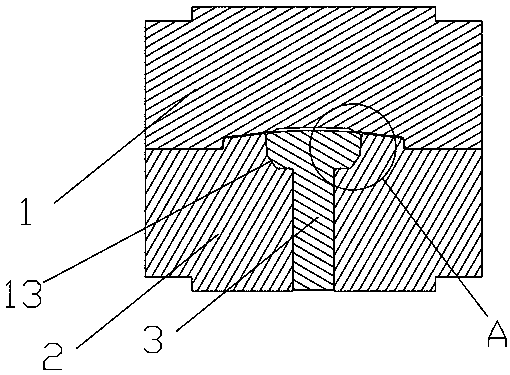

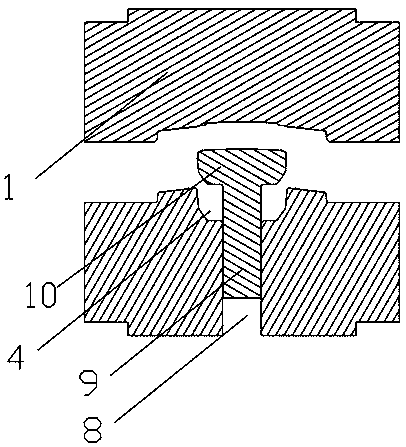

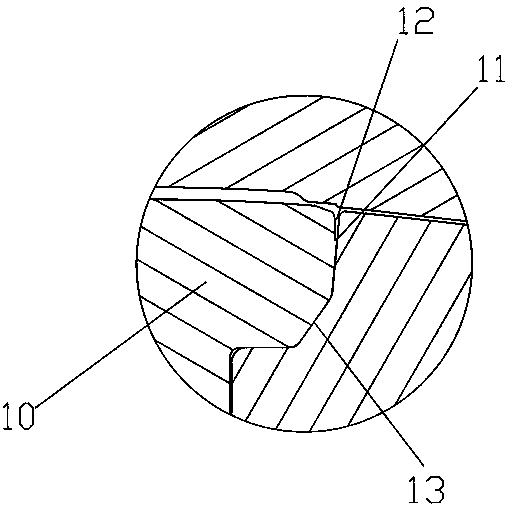

[0028] For specific implementation: see Figure 1 to Figure 3 , a combined mold for an aircraft window frame, comprising an upper mold 1, a lower mold 2 and an inner mold 3, and the upper end of the lower mold 2 is provided with a groove 4 corresponding to the profile of the rib portion of the aircraft window frame 5 The upper groove wall of the groove 4 is provided with a first forming surface corresponding to the outer shape of the rib portion of the aircraft window frame forging, a through hole 8 is provided in the center of the bottom of the groove 4, and the inner mold 3 includes a through hole inserted into the through hole. 8 and the push rod 9 that can be ejected upwards and the forming end 10 that is located above the through hole 8 and matches the shape of the groove 4, the forming end 10 is connected to one end of the push rod 9, and the upper p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com