Three-sided tooth cold extrusion forming die at the end of the bushing

A cold extrusion and forming die technology, applied in the direction of metal extrusion die, etc., can solve the problem of low mechanical strength of the input shaft sleeve, and achieve the effect of good metal fiber integrity, dense organization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

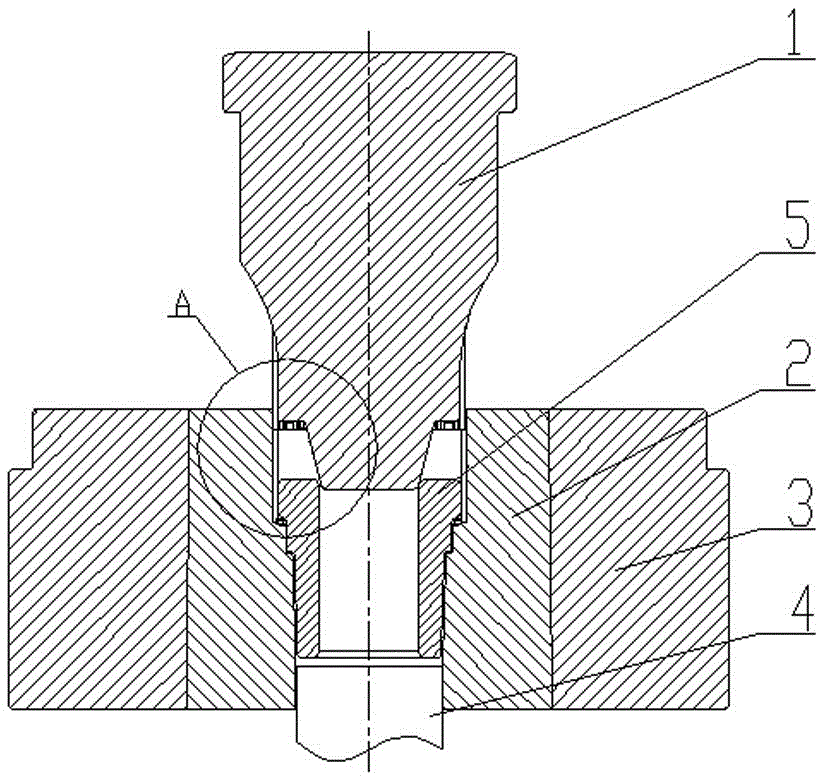

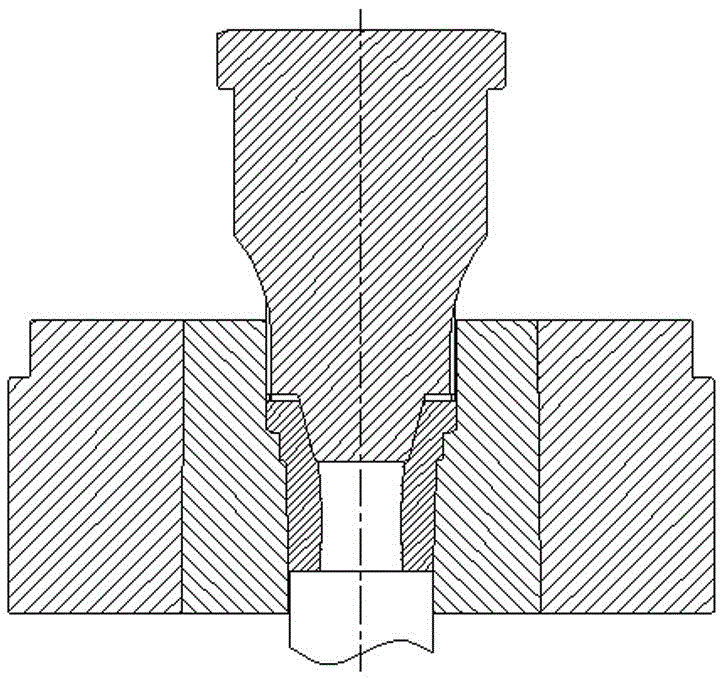

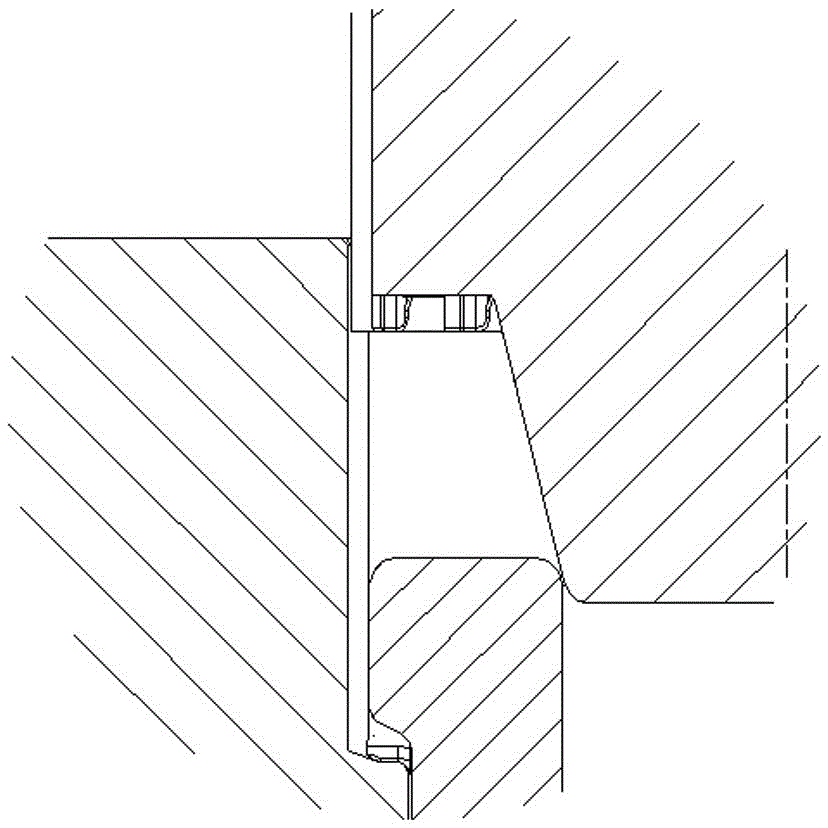

[0019] figure 1 and figure 2 The three-sided gear cold extrusion forming die at the end of the sleeve is composed of an upper die 1, a lower die 2, an insert 3 and a push rod 4. The insert 3 is a round sleeve with a built-in axial through hole, and it is installed on the supporting press workbench to position and install the lower die 2 . The vertically placed lower mold 2 is placed in the axial through hole of the insert 3, and the interference fit between the two forms the radial reinforcement structure of the insert 3 to the lower mold 2, which can reduce the occurrence of cracking accidents of the lower mold 2. The lower die 2 is provided with a die cavity matched with the blank 5, the blank 5 placed in the die cavity of the lower die 2 is axially limited by the push rod 4 at the bottom, and the upper part of the die cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com