Illumination device of ethylene-vinyl acetate (EVA) film extruder

A lighting device and extruder technology, applied in the field of lighting devices, can solve the problems of increasing the labor intensity of workers, reading laboriously, affecting production progress, etc., so as to improve production safety and equipment service life, reduce misoperation, Protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

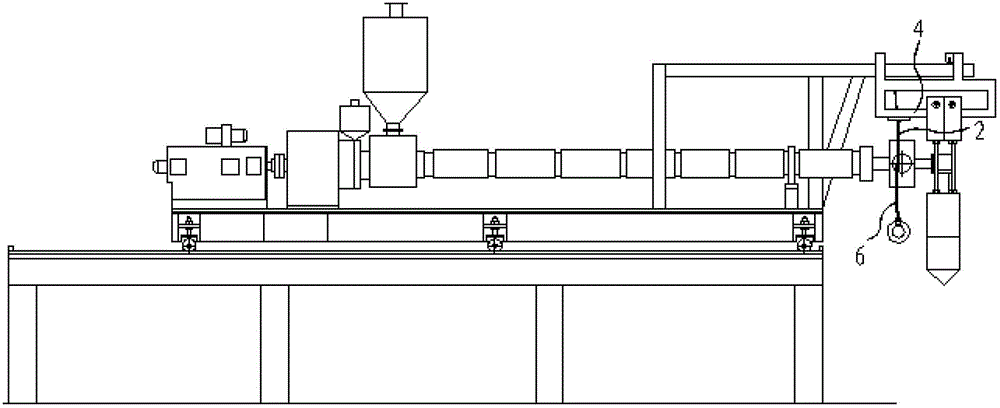

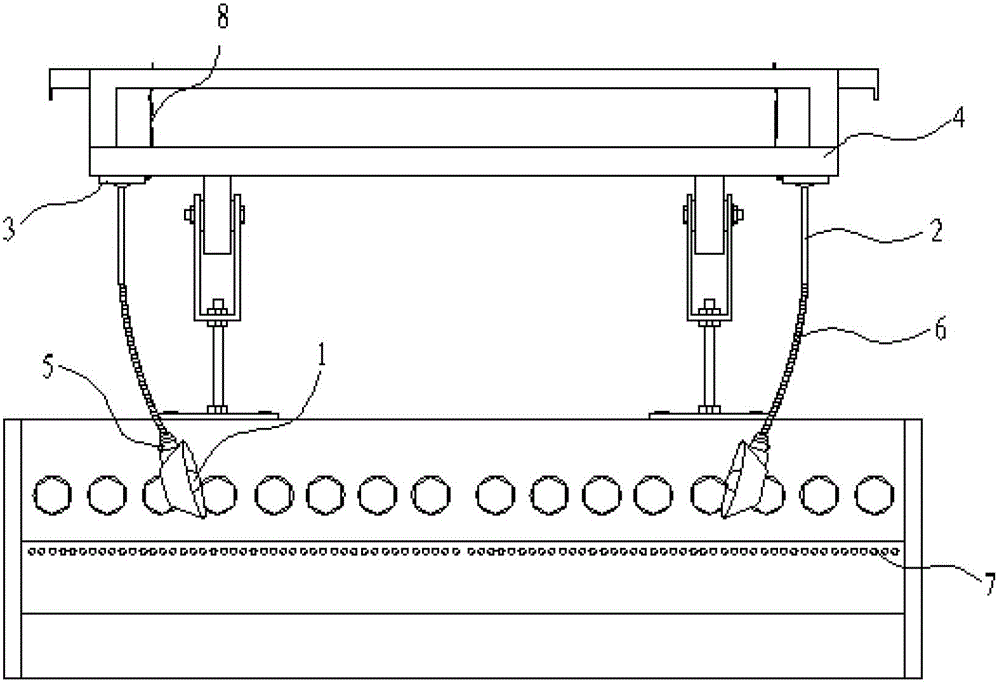

[0020] Embodiment one: if figure 1 , 2 As shown, it is a lighting device on an EVA film extruder according to the present invention, including a bulb 1, a connecting rod and a base 3, the bulb 1 is a high-power energy-saving bulb 1, and the bottom of the base 3 is fixed on a hoisting On the frame 4 of the die head, one end of the connecting rod is rotatably connected to the base 3, and the other end is connected to the bulb 1 through the lamp holder 5, and the electric wire 8 in the lamp holder 5 passes through the connecting rod The inner cavity and the base 3 are connected to the power supply on the extruder, and a PVC protective tube (not shown) is set on the drawn electric wire 8 to ensure the safety of the electric wire 8.

[0021] The connecting rod is composed of a straight rod part 2 and a curved rod part 6, the straight rod part 2 is connected to the base 3 in rotation, the curved rod part 6 is connected to the lamp holder 5, and the curved rod part 6 consists of a ...

Embodiment 2

[0022] Embodiment 2: A lighting device on an EVA film extruder. In this embodiment, its structure is similar to that of Embodiment 1. The difference is that the straight rod part is composed of inner and outer telescopic sleeves. The outer telescopic sleeve is provided with a positioning hole, and the inner telescopic sleeve is provided with a protrusion matching the positioning hole. The straight rod part is retractable, which is more convenient for the operator to adjust the light. When it is not in use, it can be stowed to reduce the interference of the lighting device on other operating procedures in the production of EVA film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com