Muck remover of TBM (tunnel boring machine) main belt conveyer

A technology of belt conveyor and main engine, which is applied in the direction of cleaning devices, transportation and packaging, and conveyor objects, etc., which can solve the problems of difficulty in manual cleaning, low efficiency, and falling of dregs, so as to reduce manual labor, improve work efficiency, The effect of combining fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

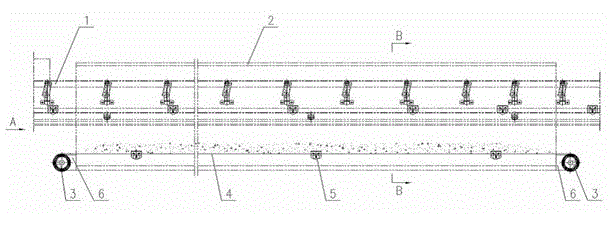

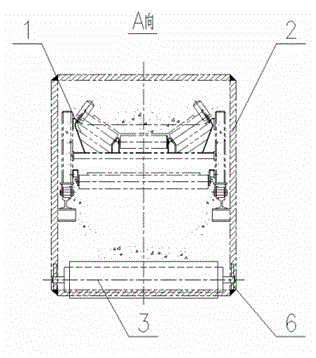

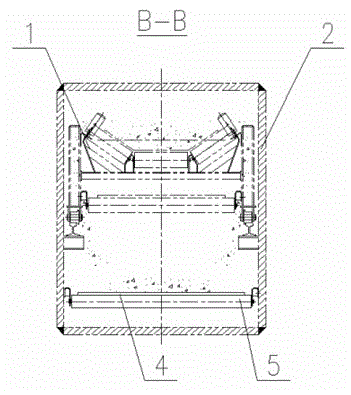

[0012] see figure 1 — image 3 , the cleaning device of the TBM main frame belt conveyor comprises: a hollow TBM main beam 2, a main engine belt conveyor 1 arranged in the TBM main beam 2, and a second belt conveyor is arranged below the main engine belt conveyor 1; the second belt The machine includes: a driving roller 3, a belt 4, and an idler roller 5; the driving roller 3 is installed on the main beam of the TBM through the driving roller bracket 6 respectively, and the driving roller bracket 6 is welded to the main beam of the TBM, and the idler roller 5 is set It is installed on the TBM main beam 2 between the front and rear two driving drums 3 , and the belt 4 is wound on the driving drum 3 and idler roller 5 .

[0013] The main belt conveyor 1 of the TBM main engine drops muck during the transportation of muck due to the mechanical vibration of the equipment, etc., and the second belt conveyor can catch it and send it out automatically, avoiding the normal operation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com