Waste organic matter continuous cracking industrial fluidized bed

An organic matter, fluidized bed technology, applied in the petroleum industry, coke oven, direct heating and dry distillation, etc., can solve the problems of low efficiency, high cost, occupation of cultivated land, etc., and achieve the effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

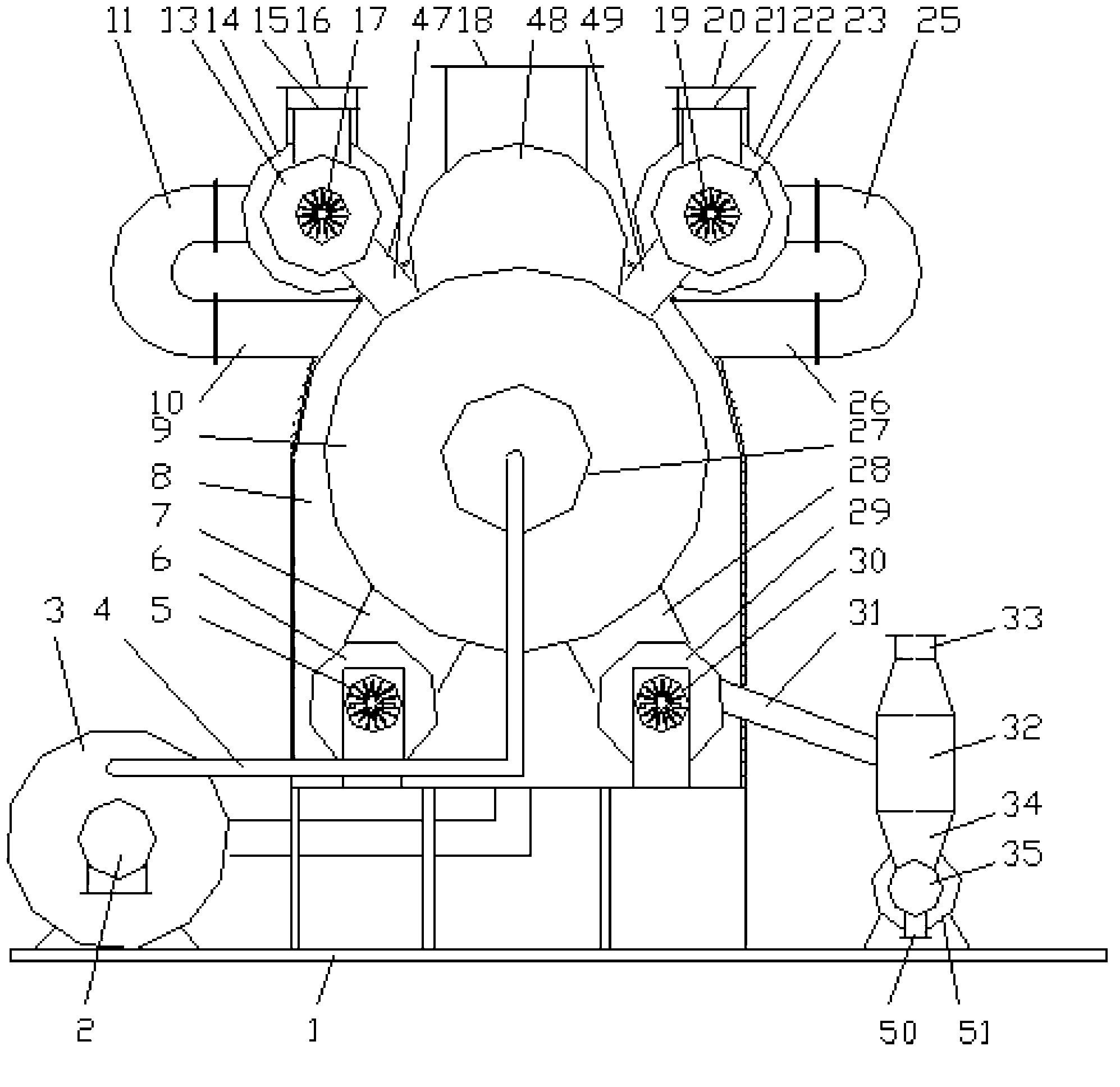

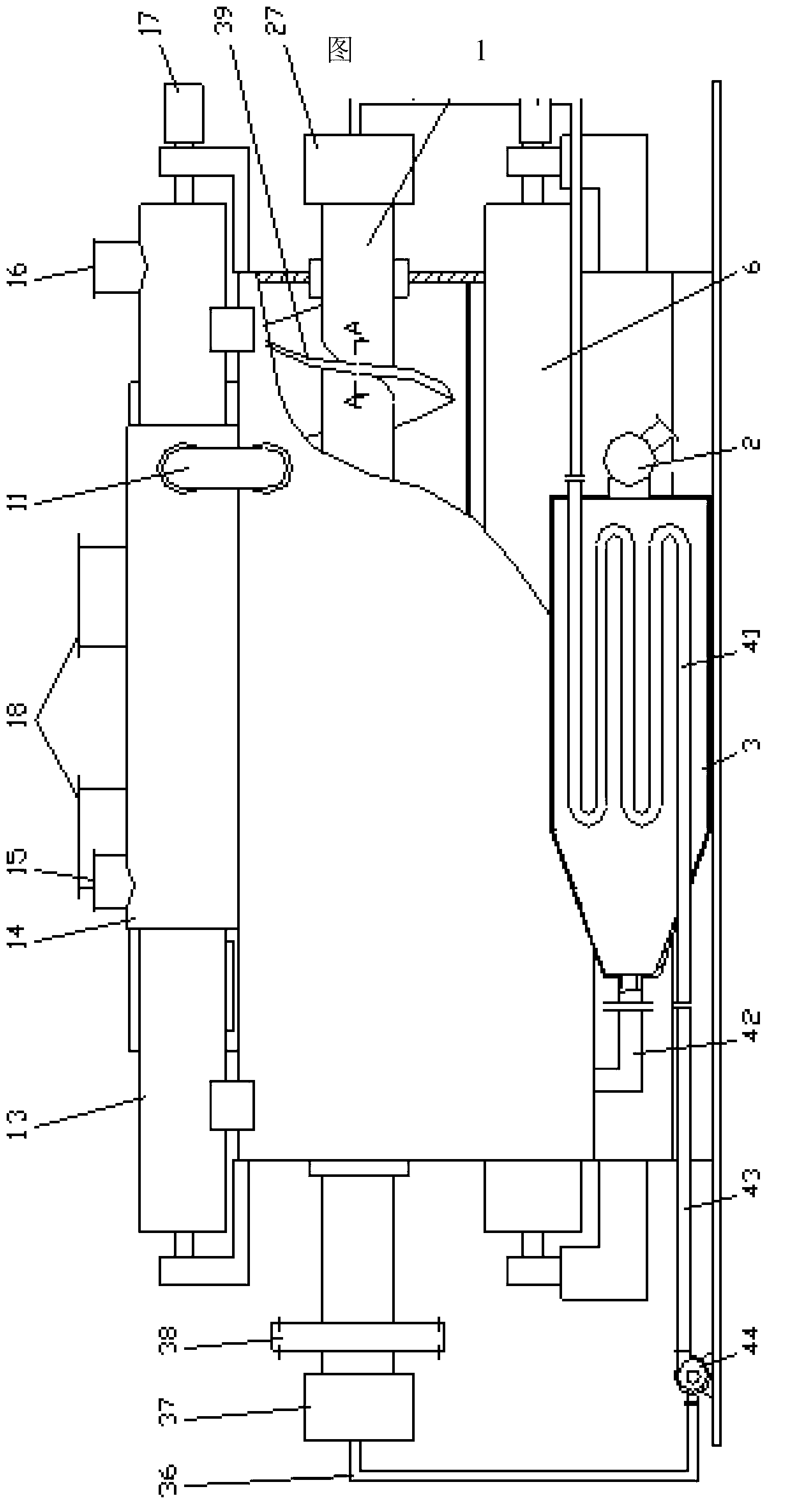

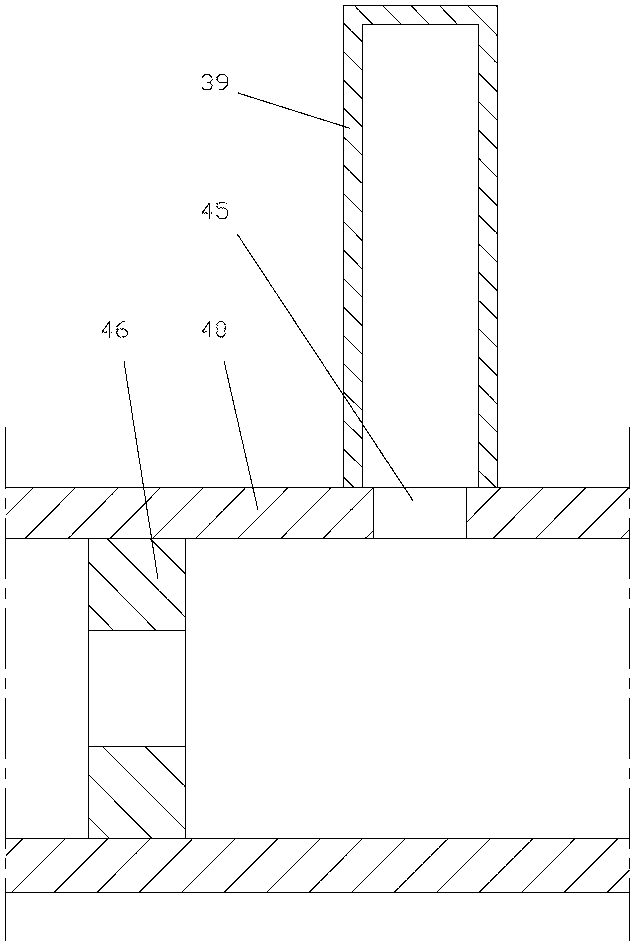

[0011] In the drawings: base 1, combustion chamber 2, hot blast stove 3, heat carrier heating circulation conveyor 6, hot gas chamber 8, cracking cylinder 9, left interface 10, left preheating feed conveyor 13, right preheating feed conveying Machine 23, right interface 26, right gas dynamic sealing joint 27, residue heating conveyor 29, gas-solid separator 32, oil-gas interface 33, slag discharger 35, left gas dynamic sealing joint 37, sprocket or gear 38, spiral piece 39, hollow shaft 40, heat exchange tube 41, blower fan 44, through hole 45, gas distribution orifice plate 46, pipeline 4, 7, 11, 25, 28, 31, 34, 42, 43, motor reducer 5, 17, 19 , 30,36, slag outlet 50, cooling water jacket 51.

[0012] Such as figure 1 , 2 As shown, the cracking cylinder 9 is fixed on the base 1, and the oil and gas collection cylinder 48 and the left and right preheating feed conveyors 13, 23 communicated with the inner cavity of the cracking cylinder 9 are sealed and fixed above the cracki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com