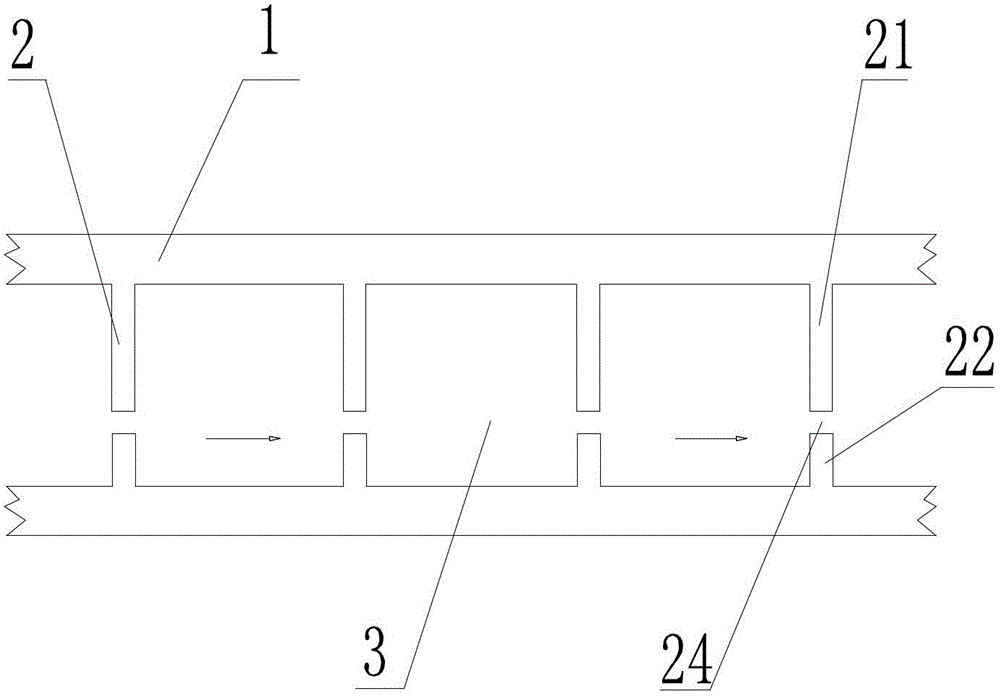

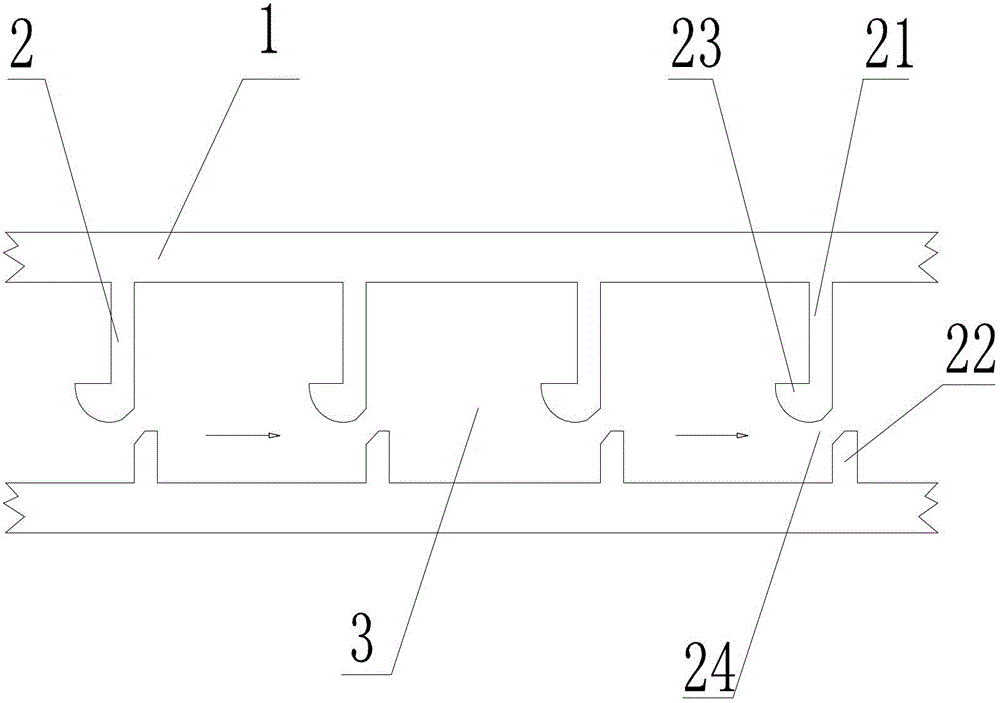

Vertical seam type fishway structure

A technology of vertical slits and fish passages, which is applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as large impact, unfavorable river ecological protection, and reduce water flow velocity, so as to avoid large water flow velocity and be beneficial to ecological protection. , Improve the effect of energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

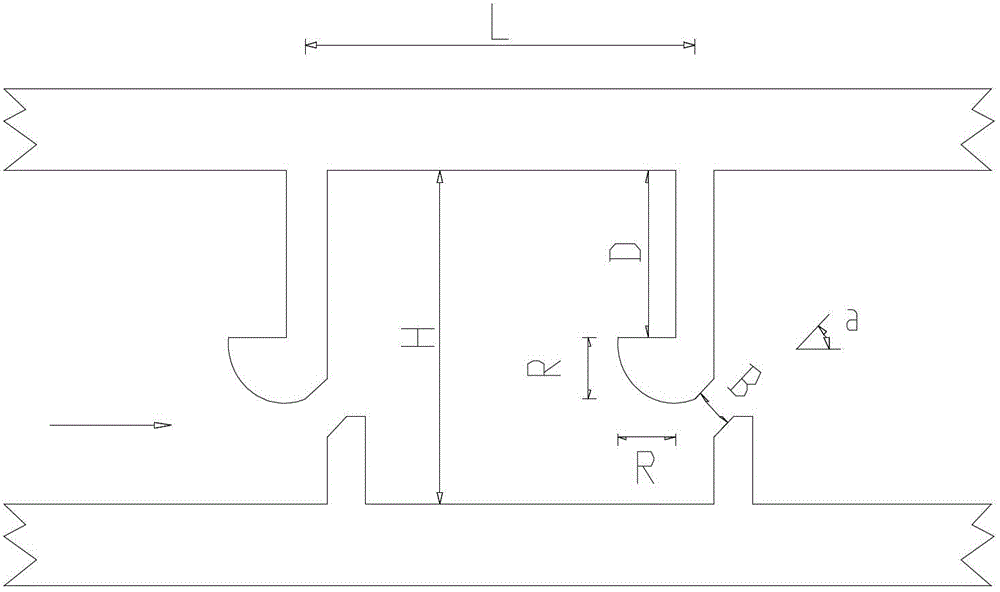

[0024] Choose three pond chamber vertical seams 24 on the vertical seam type fishway structure described in the present invention and detect the water flow velocity at respective pond chamber vertical seam 24 places, also choose three pond chamber vertical seam 24 places on the prior art vertical seam type fishway structure Pool chamber vertical seam 24 and detect the water flow velocity at respective pool chamber vertical seam 24 places, and three pond chamber vertical seams 24 that the present invention chooses and the three pond chamber vertical seams 24 that prior art chooses are in the position in respective fishway Identical, and numbered as 1#, 2#, 3# in pairs, promptly be positioned at the pool chamber vertical seam 24 numbering identical in the same position.

[0025] The following table is a comparison table of the water flow velocity at 24 vertical seams of the tank chamber between the vertical seam fishway structure of the present invention and the vertical seam fis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com