Onboard temporary support machine

A technology of temporary support and support machine, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of long support distance, wide adaptability of roadway, strong support force, etc., and achieve efficiency improvement and enhanced The effect of advanced support ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

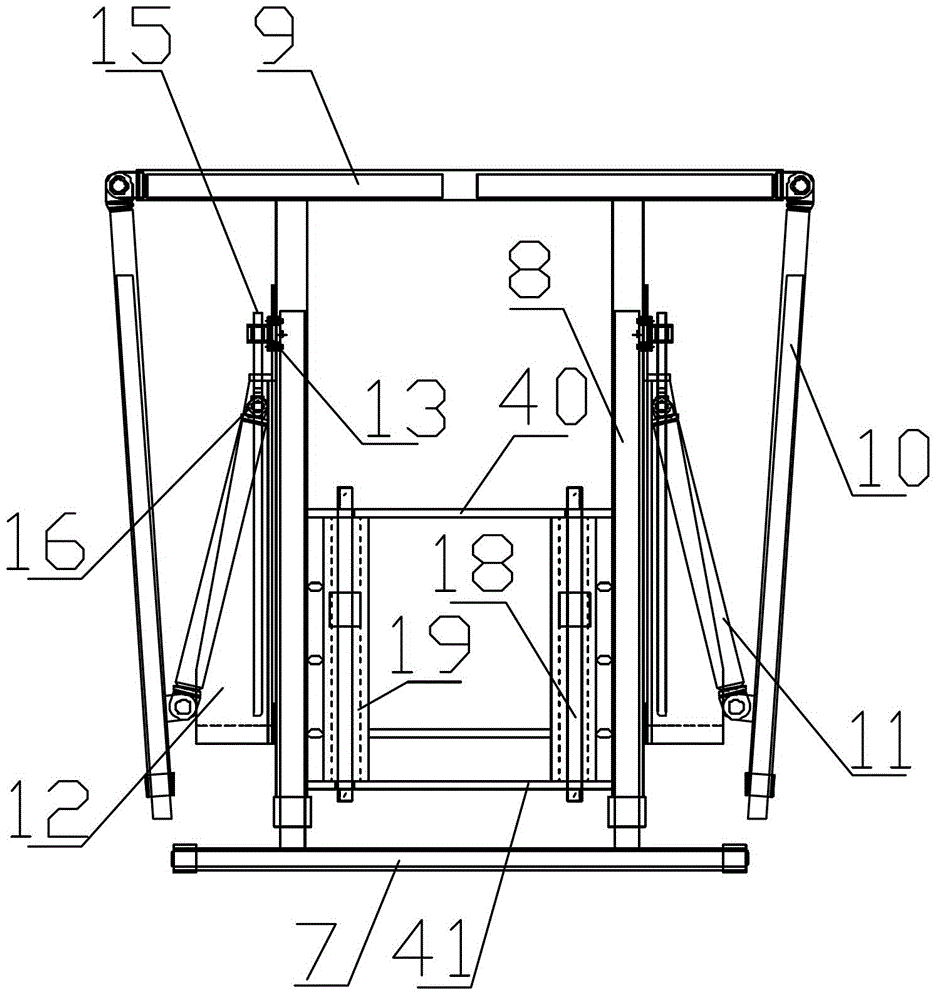

[0046] The airborne temporary support machine of the present invention is installed on the parts to be supported (such as: roadheader, etc.), and the support machine is provided with a single-layer support frame body, between the parts to be supported and the single-layer support frame body The front vertical lifting support device and the rear vertical lifting support device are installed in the room.

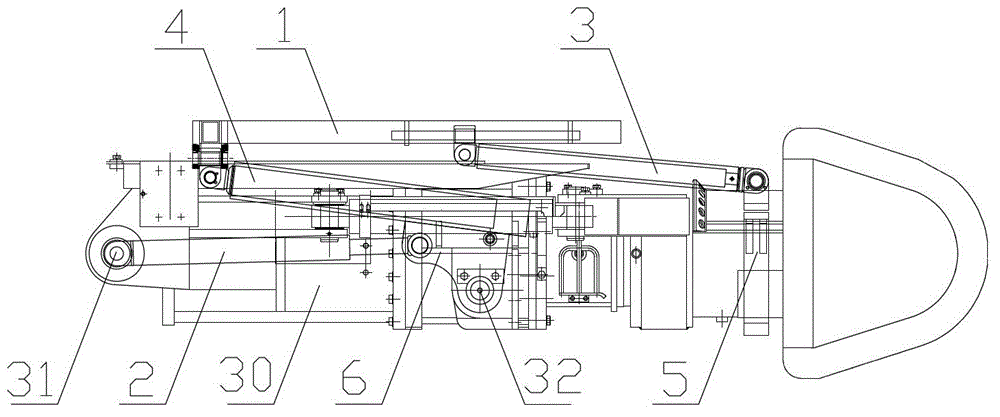

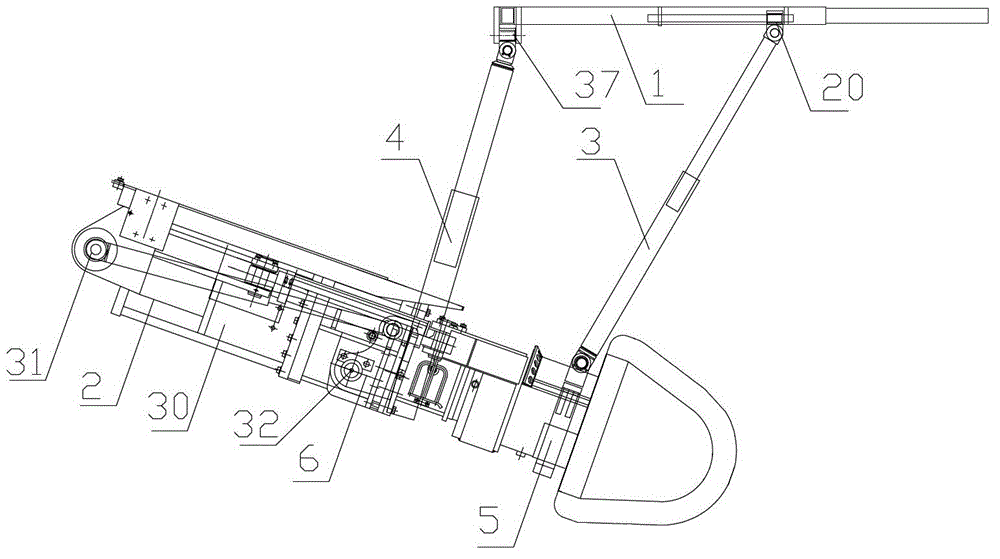

[0047] Such as Figure 1~4 As shown, the airborne temporary support machine is installed on the cutting part 30 of the roadheader through the positioning pin shaft, and forms an airborne integrated connection with the cutting part of the roadheader. A front vertical lift support device 3 and a rear vertical lift support device 4 are additionally installed between the cutting part 30 of the roadheader and the single-layer support frame body 1 . The airborne temporary support machine mainly includes: single-layer support frame body 1, vertical flip cylinder 2, front vertical li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com