Full-ball angular contact bearing trapping tool device with outer ring having ball locking mouths

An angular contact bearing, full ball technology, used in shafts and bearings, bearing components, mechanical equipment, etc., can solve problems such as being unsuitable for mass production, worker safety hazards, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

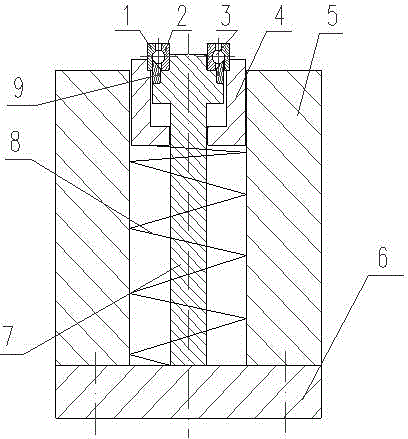

[0015] The positioning shaft 7 is processed with multiple steps, which can be positioned with a small gap with the inner ring 2, and another step can be interference fit with the steel ball positioning ring 9; the middle sliding sleeve 4 slides with the positioning shaft 7 and the outer sleeve 5 at the same time Matching, the positioning groove is processed on the sliding sleeve 4, which is used to place the bearing outer ring 1. The spring 8 strings are on the positioning shaft 1 to withstand the sliding sleeve 4 at the same time, so that the sliding sleeve 4 can slide to the highest point along the positioning shaft 1, so that the sliding sleeve 4 and the steel ball positioning ring 9 completely position the steel ball in a fixed position. on the circumference.

[0016] When fitting, put the inner ring 2 on the positioning shaft 1, then put the steel ball between the steel ball positioning ring 9 and the middle sliding sleeve 4, and finally put the outer ring 1 into the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com