Built-in driven pneumatic valve

A pneumatic valve, driven technology, applied to pneumatic valves. It can solve the problems of short service life, inconvenient installation and debugging, and large volume of the valve, and achieve the effect of no relative friction, compact structure and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

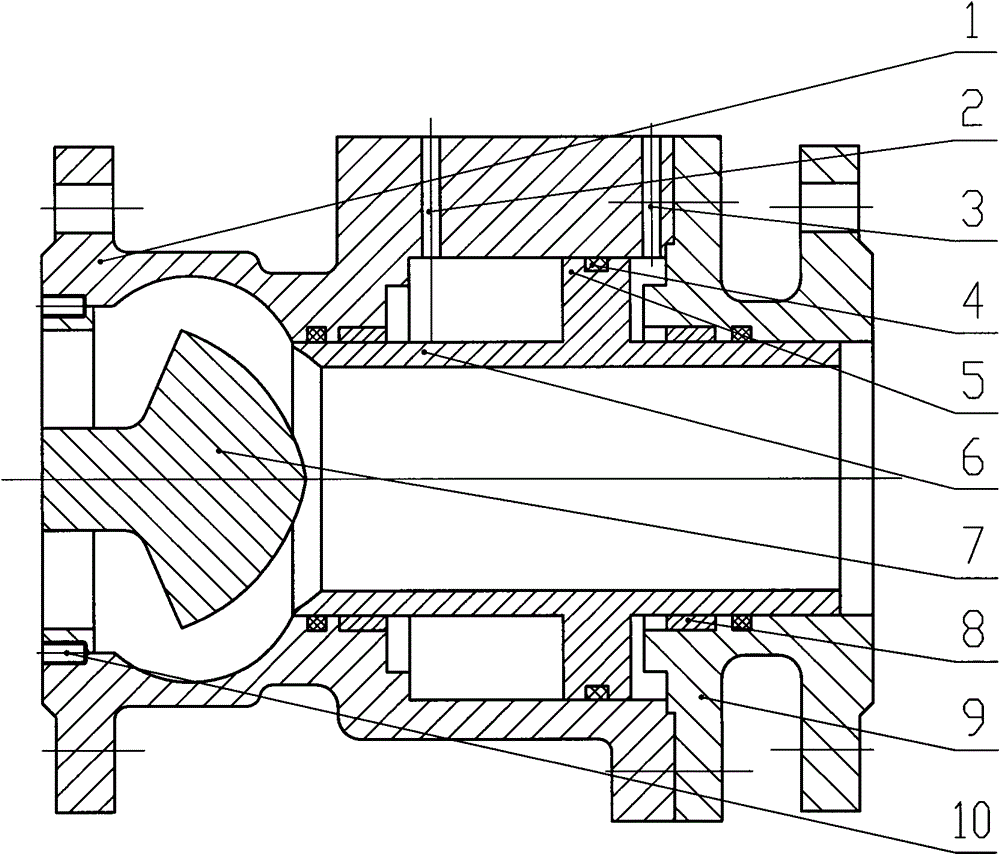

[0010] Such as figure 1 As shown, a built-in driven pneumatic valve includes a valve body 1, a valve cover 9, and a valve disc 7. The valve disc 7 is fixed in the valve body 1 by screws 10, and the valve cover 9 and the valve body 1 are connected by fasteners. There is also a hollow valve core 6 installed in the valve body 1, the front end of the valve core 6 forms a sealing pair with the sealing surface of the valve disc 7, and there is a boss 5 in the middle of the valve core 6, and the boss 5 and the valve body 1 pass through an O-ring 4 sealing, between the front end of the valve core 6 and the valve body 1 and between the rear end of the valve core 6 and the valve cover 9 are sealed by an O-ring 4 , and the valve body 1 at the front end of the boss 5 of the valve core 6 is provided with a valve opening inlet The air port 2 is opened on the valve body 1 of the boss 5 of the valve core 6 to open the valve air inlet 3 . Between the front end of the valve core 6 and the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com