Fixed support device and operating method thereof

A technology for fixing brackets and fixing foundations. It is applied in the direction of pipeline brackets, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as high labor intensity, inconvenient installation, and troublesome replacement, so as to reduce on-site workload and avoid replacement. Troublesome, easy to install and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

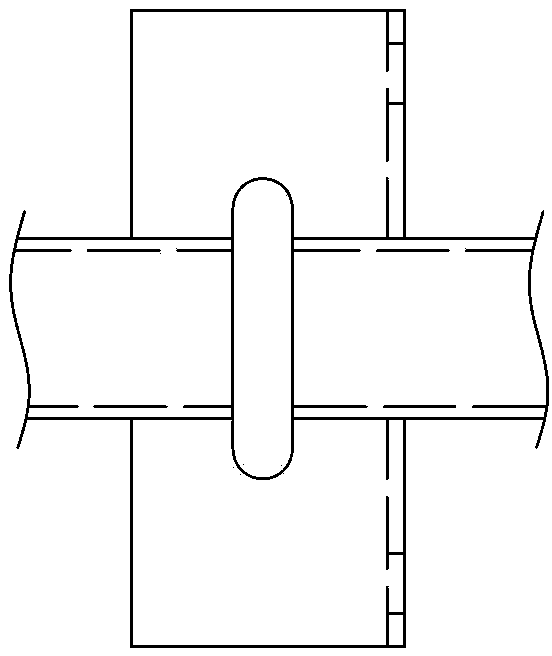

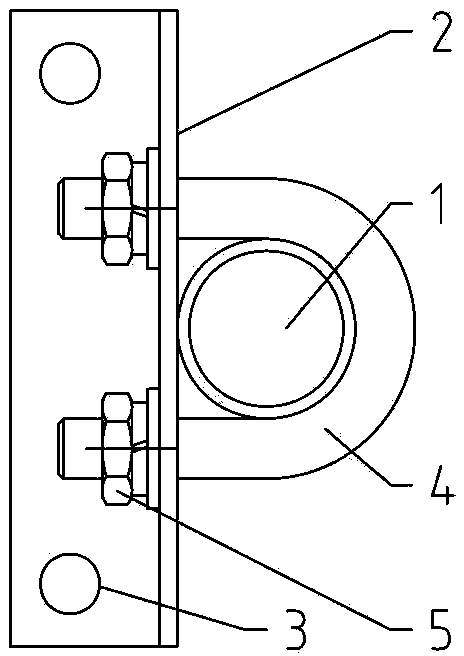

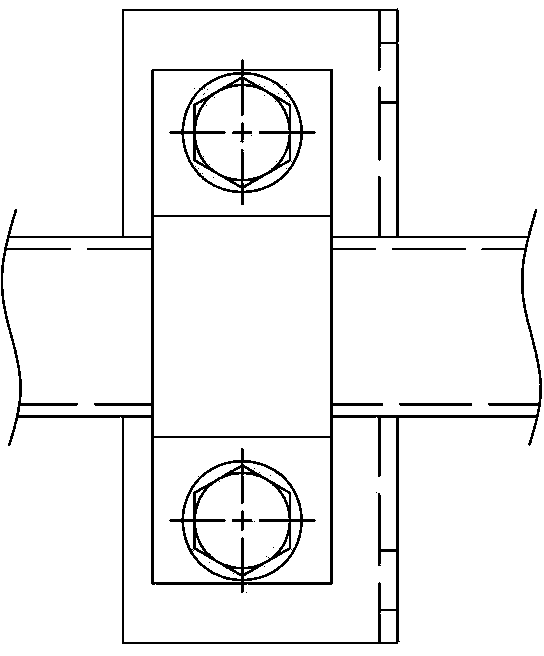

[0082] see Figure 7 to Figure 15 , a fixed bracket device, comprising: a bracket member 10, a hanging plate 9, a first bolt 22 and a bolt member 11, the bracket member 10 includes a bracket 12, and the bracket 12 is provided with two for connecting with field machines or parts The fixing hole 3 and two via holes 13 for connecting with the hanging board 9, the cross section of the hanging board 9 is "Z" shape, one end of which is connected with the bracket member 10 through the first bolt 22, and the other end is provided with a "U-shaped" opening 17, and the bracket member 10 and the hanging plate 9 form a cavity 18 with one side open. The bolt member 11 fixes the “U-shaped” open end of the hanging plate 9 to the bracket member 10 .

[0083] The fixed bracket device in this embodiment adopts a screw-fixed bracket component structure, which is suitable for installation conditions requiring a small adjustment margin. like Figure 11 , 12 As shown, this embodiment also inclu...

Embodiment 2

[0094] The structure and operation method of the fixing bracket device adopting the screw-fixed bracket component structure of the present invention have been introduced in detail above. Due to the high uncertainty in the field, sometimes a large adjustment margin is required. Therefore, the present invention can also adopt a threaded adjustable bracket structure to improve adaptability.

[0095] like Figure 16 to Figure 22 As shown, a fixed bracket device includes: a bracket member 10, a hanging plate 9, a first bolt 22 and a bolt member 11, the bracket member 10 includes a bracket 12, and the bracket 12 is provided with two The connecting fixing hole 3 and two through holes 13 for connecting with the hanging plate 9, wherein the through holes 13 for connecting with the bolt member 11 are elongated, and the cross-sectional area of the bracket 12 is "U" shaped , to form the guide groove 25 of the sliding threaded plate 24. The cross-section of the hanging plate 9 is “Z”-s...

Embodiment 3

[0104] The structure and operation method of the fixing bracket device adopting the screw-fixed bracket component structure and the thread-adjustable bracket component structure of the present invention have been introduced in detail above. In addition, the present invention can also adopt a chute-type support member structure, and the positions of the first bolt and the bolt member can be adjusted arbitrarily in the chute, which has excellent adaptability.

[0105] like Figure 23 to Figure 29 As shown, a fixed support device includes: a support member 10, a hanging plate 9, a first bolt 22 and a bolt member 11, and the support member 10 is provided with two through chute 26, which are respectively used to connect with the field machine or zero Component connections, and connections to pegboards. The cross-section of the hanging plate 9 is “Z”-shaped, one end of which is connected to the support member 10 through the first bolt 22, and the other end is provided with a “U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com