ZnO (zinc oxide) homogeneous pn junction and preparation method of ZnO homogeneous pn junction

A pn junction, n-type technology, applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of ZnO homogeneous pn junctions, such as no patents and scientific research reports, to reduce the preparation cost, simplify the preparation method, The effect of enriching the composition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

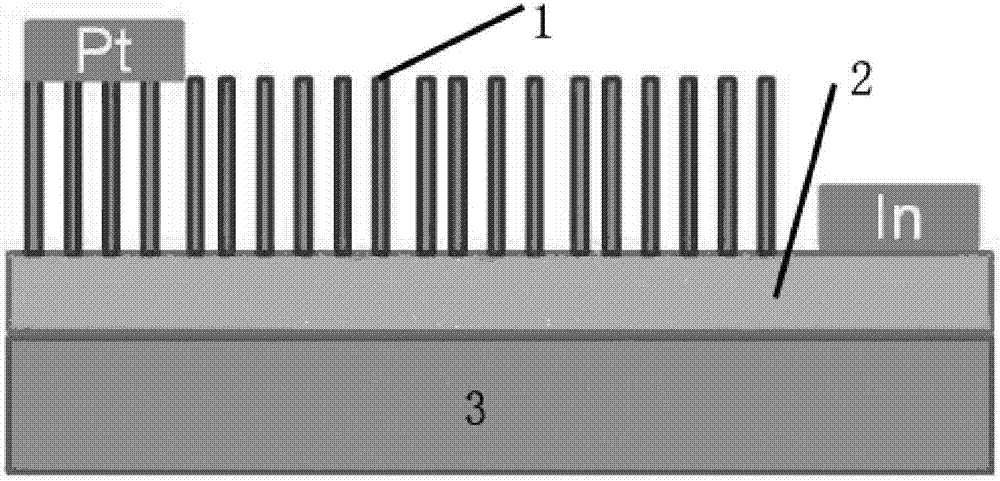

[0030] An n-type Al-doped ZnO thin film with (002) orientation and an Al doping concentration of 3 at.% was deposited on a glass substrate by ion beam sputtering.

[0031] Mix the aqueous solutions of zinc nitrate, hexamethylenetetramine and antimony trichloride with a concentration of 2.5mM, 2.5mM and 0.25mM in a volume ratio of 1:1:1 for a total of 150ml, and adjust the pH value of the mixed solution at 3 with nitric acid. , the mixed solution was heated to 65°C.

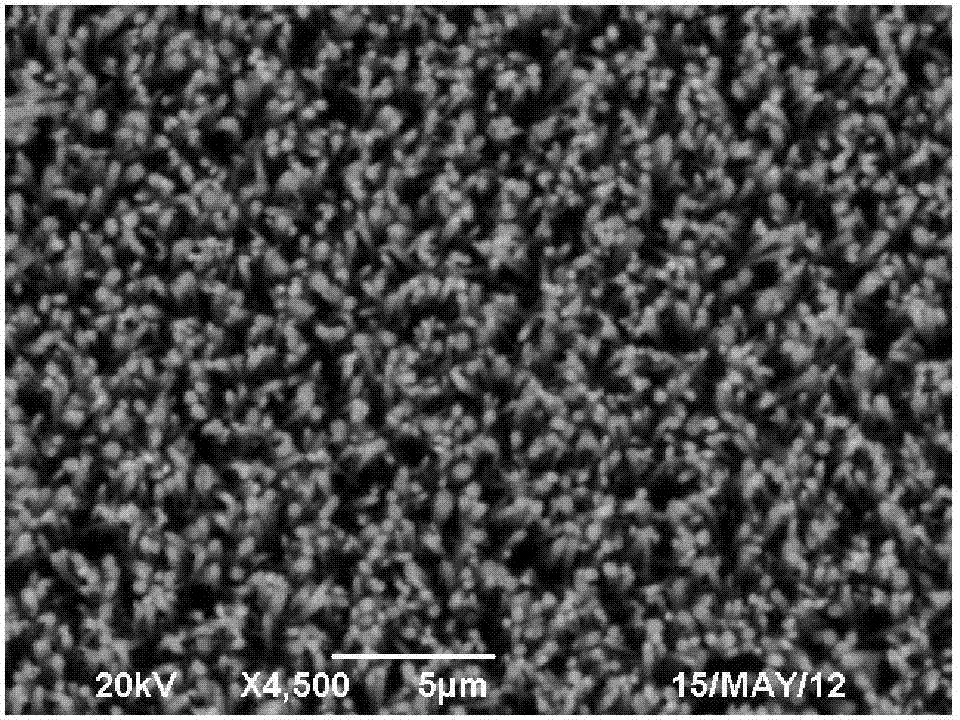

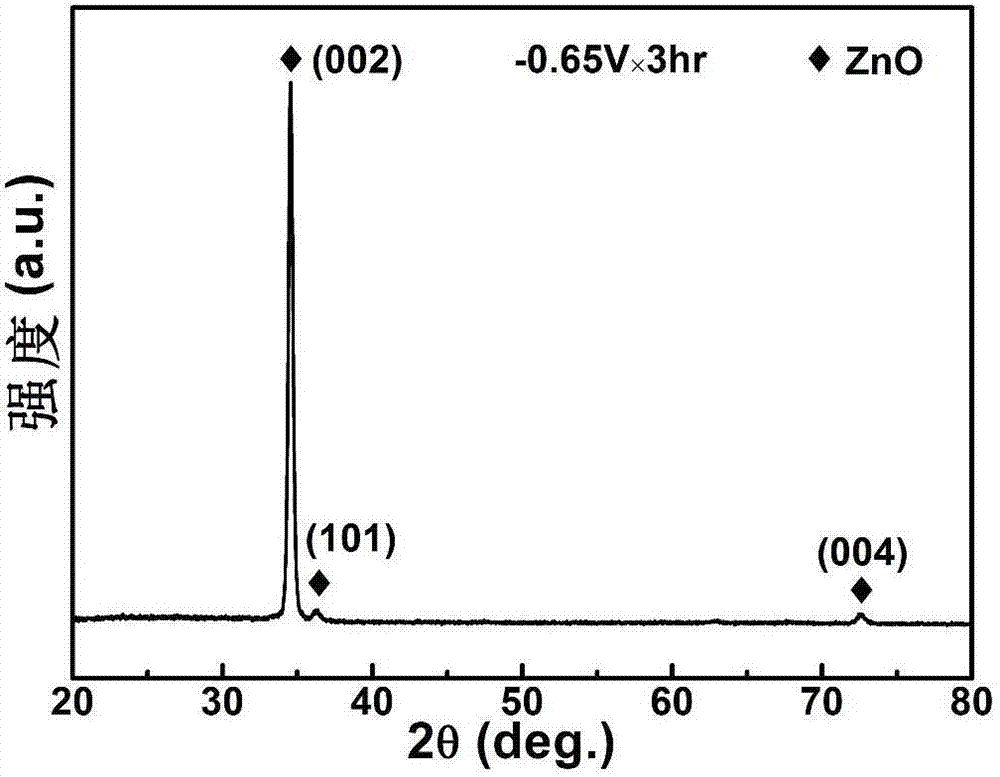

[0032] By electrochemical deposition, the glass substrate deposited with n-type Al-doped ZnO film was inserted into the above mixed solution as the working electrode, with Ag / AgCl as the reference electrode and Pt wire as the counter electrode, and the potential of the working electrode was compared to Adjust the reference electrode to -0.65V, deposit for 3 hours, and grow on the n-type Al-doped ZnO thin film to obtain a p-type Sb-doped ZnO nanorod array with a Sb doping concentration of 8.3 at.%, thereby making a...

Embodiment 2

[0036]An n-type Al-doped ZnO thin film with (002) orientation and an Al doping concentration of 3 at.% was deposited on a glass substrate by ion beam sputtering.

[0037] The aqueous solutions of zinc nitrate, hexamethylenetetramine and antimony trichloride with a concentration of 5mM, 5mM, and 0.0625mM were mixed in a volume ratio of 1:1:1 for a total of 150ml, and the pH value of the mixed solution was adjusted to 5 with nitric acid. The mixed solution was heated to 75°C.

[0038] By electrochemical deposition, the glass substrate deposited with n-type Al-doped ZnO film was inserted into the above mixed solution as the working electrode, with Ag / AgCl as the reference electrode and Pt wire as the counter electrode, and the potential of the working electrode was compared to Adjust the reference electrode to -1.05V, deposit for 30 minutes, and grow on the n-type Al-doped ZnO thin film to obtain a p-type Sb-doped ZnO nanorod array with a Sb doping concentration of 0.9 at.%, ther...

Embodiment 3

[0042] An n-type Al-doped ZnO thin film with (002) orientation and an Al doping concentration of 3 at.% was deposited on a glass substrate by ion beam sputtering.

[0043] The aqueous solutions of zinc nitrate, hexamethylenetetramine and antimony trichloride with concentrations of 5mM, 2.5mM and 0.125mM were mixed in a volume ratio of 1:1:1 for a total of 150ml, and the pH value of the mixed solution was adjusted to 7 with ammonia water. The mixed solution was heated to 90°C.

[0044] By electrochemical deposition, the glass substrate deposited with n-type Al-doped ZnO film was inserted into the above mixed solution as the working electrode, with Ag / AgCl as the reference electrode and Pt wire as the counter electrode, and the potential of the working electrode was compared to Adjust the reference electrode to -0.8V, deposit for 6 hours, and grow on the n-type Al-doped ZnO thin film to obtain a p-type Sb-doped ZnO nanorod array with a Sb doping concentration of 4.8 at.%, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com