Special mango liquid compound fertilizer and preparation method thereof

A compound fertilizer and liquid technology, which is applied in the field of mango special liquid compound fertilizer and its preparation, can solve the problems of insufficient calcium and magnesium content, component loss, and reduced fertilizer effect, etc., and achieve easy penetration, easy absorption, easy absorption and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A special liquid compound fertilizer for mango, comprising the following raw materials in parts by weight: 40 parts of fermentation broth, 1 part of potassium nitrate, 5 parts of urea, 2 parts of potassium dihydrogen phosphate, 0.5 parts of magnesium sulfate, 0.5 parts of calcium sulfate, and 0.5 parts of trace elements 1 part of rubber liquid, wherein trace elements include the following elements in parts by weight: 0.2 part of boron, 0.1 part of zinc, 0.2% of iron, 0.4% of copper, and 0.1 part of sodium molybdate.

Embodiment 2

[0026] A special liquid compound fertilizer for mango, comprising the following raw materials in parts by weight: 60 parts of fermentation broth, 8 parts of potassium nitrate, 10 parts of urea, 10 parts of potassium dihydrogen phosphate, 3 parts of magnesium sulfate, 3 parts of calcium sulfate, and 5 parts of trace elements 3 parts, 3 parts of rubber liquid, wherein the trace elements include the following elements in parts by weight: 3 parts of boron, 4 parts of zinc, 3% of iron, 1% of copper, and 0.5 part of sodium molybdate.

Embodiment 3

[0028] A special liquid compound fertilizer for mango, comprising the following raw materials in parts by weight: 80 parts of fermentation broth, 15 parts of potassium nitrate, 20 parts of urea, 15 parts of potassium dihydrogen phosphate, 5 parts of magnesium sulfate, 5 parts of calcium sulfate, and 10 parts of trace elements 5 parts, 5 parts of rubber liquid, wherein the trace elements include the following elements in parts by weight: 5 parts of boron, 8 parts of zinc, 5% of iron, 2% of copper, and 1 part of sodium molybdate.

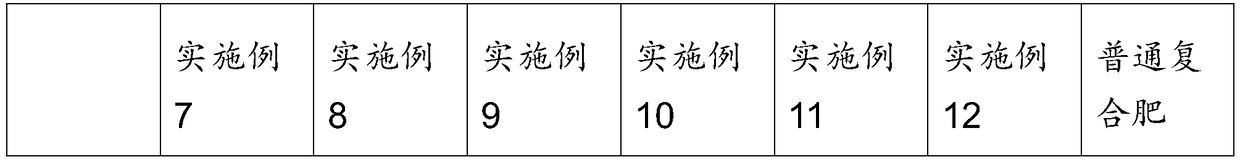

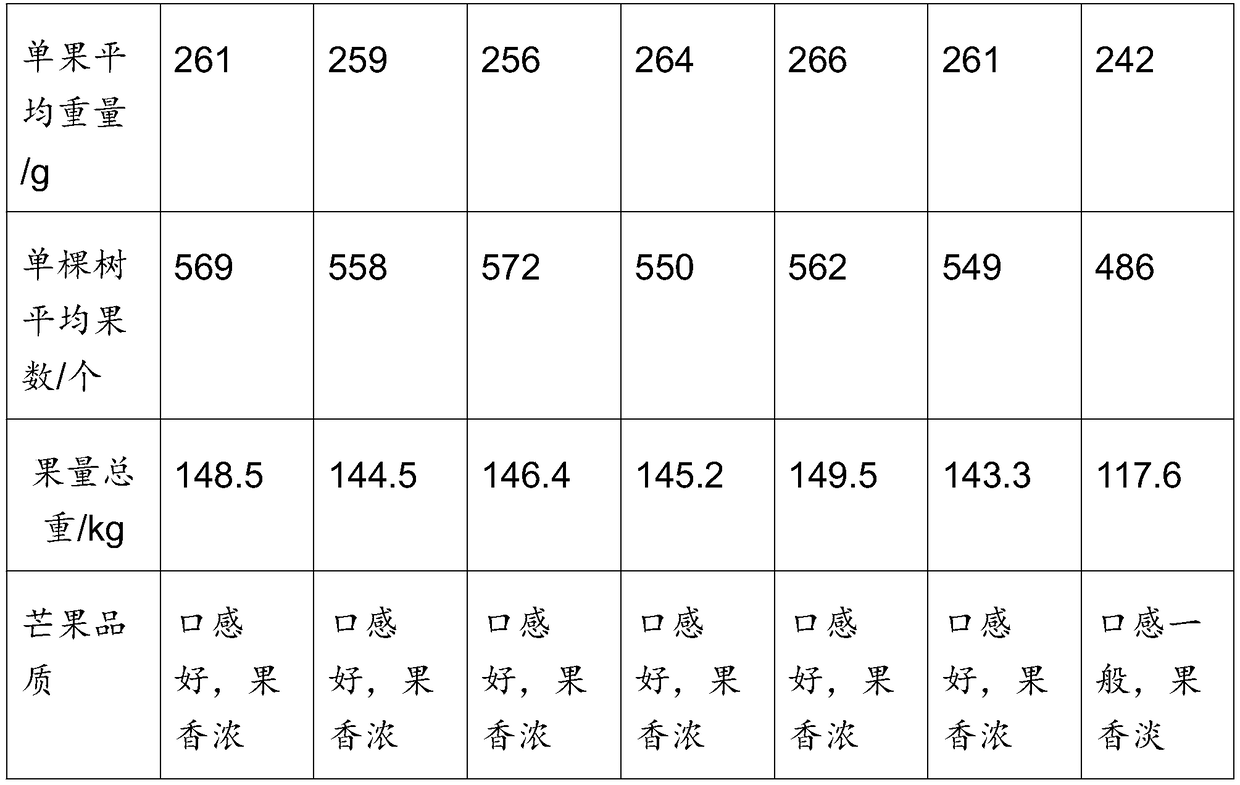

[0029] The fermented liquid in embodiment 1, embodiment 2 and embodiment 3 is respectively the preparation method in embodiment 4, embodiment 5 and embodiment 6, the compound fertilizer prepared in embodiment 1~embodiment 3 and the commercially available The results of some component content tests compared with ordinary compound fertilizers are as follows:

[0030]

[0031] As can be seen from the data in the above table, the water-soluble c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com