Installing structure of high-efficiency air filter

A technology of high-efficiency air and installation structure, applied in the direction of suction filter, etc., can solve the problems of cumbersome installation of hepa, burnout of vacuum motor, and many complicated parts, and achieve the effect of simple and stable structure, ensuring correct installation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

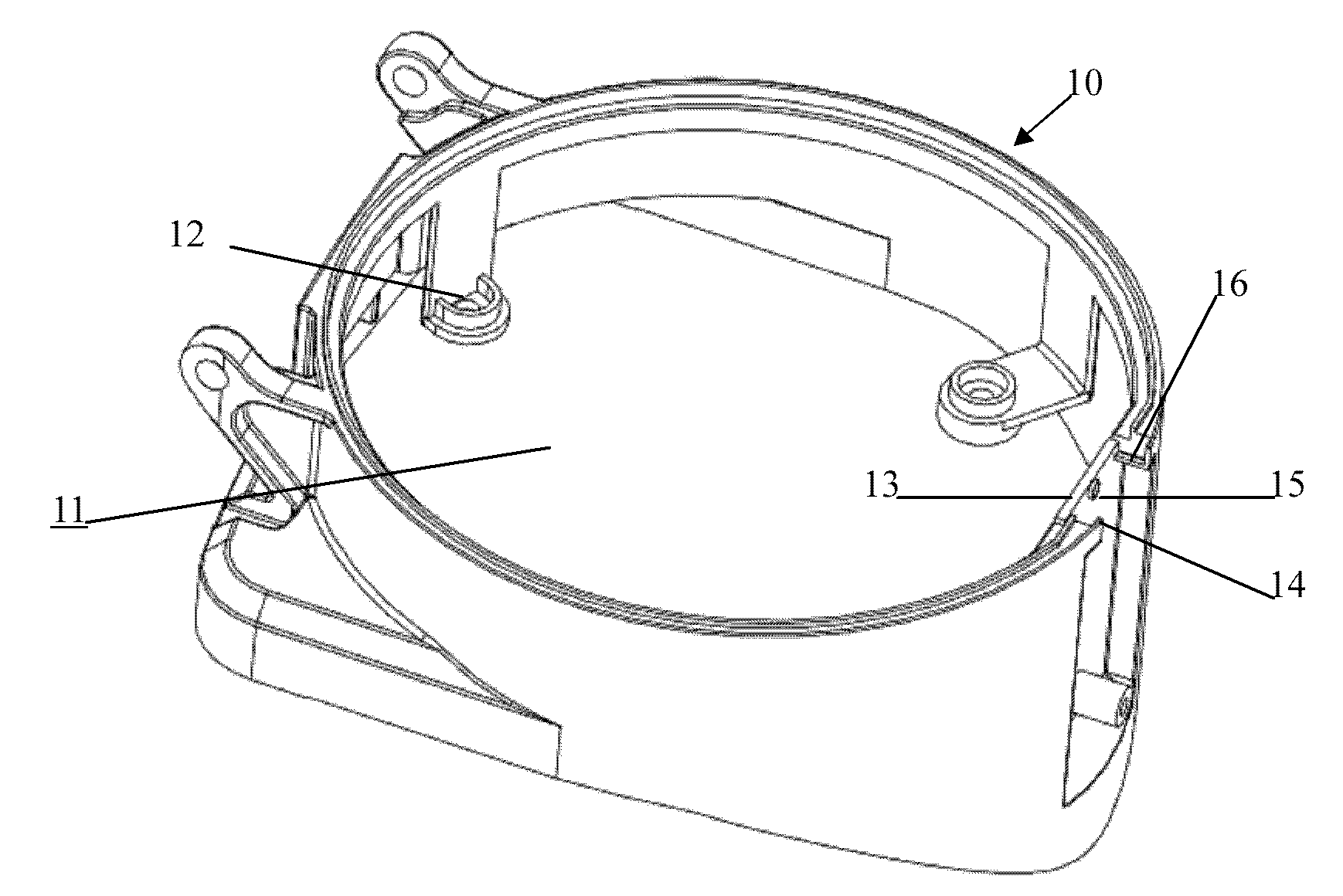

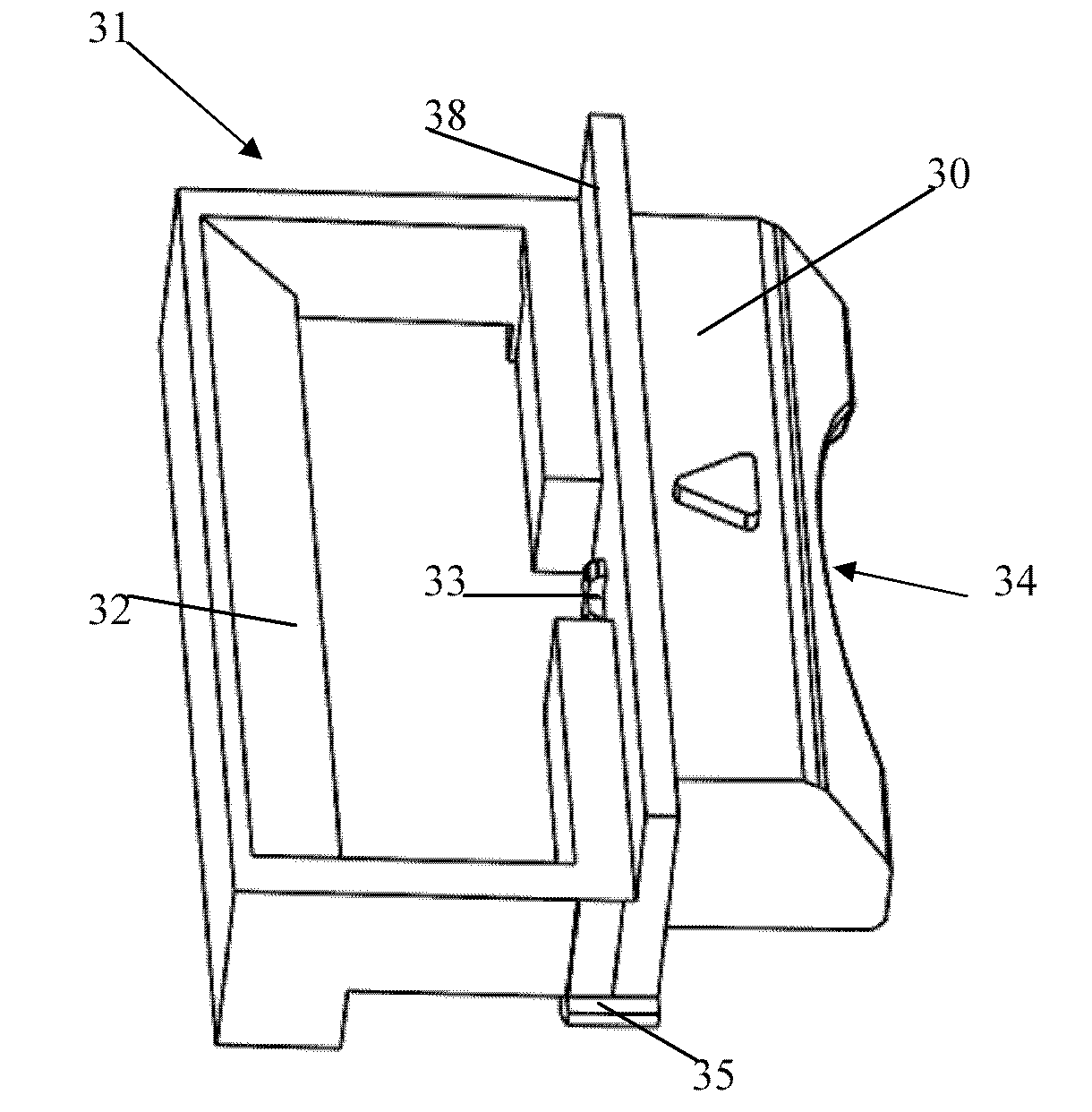

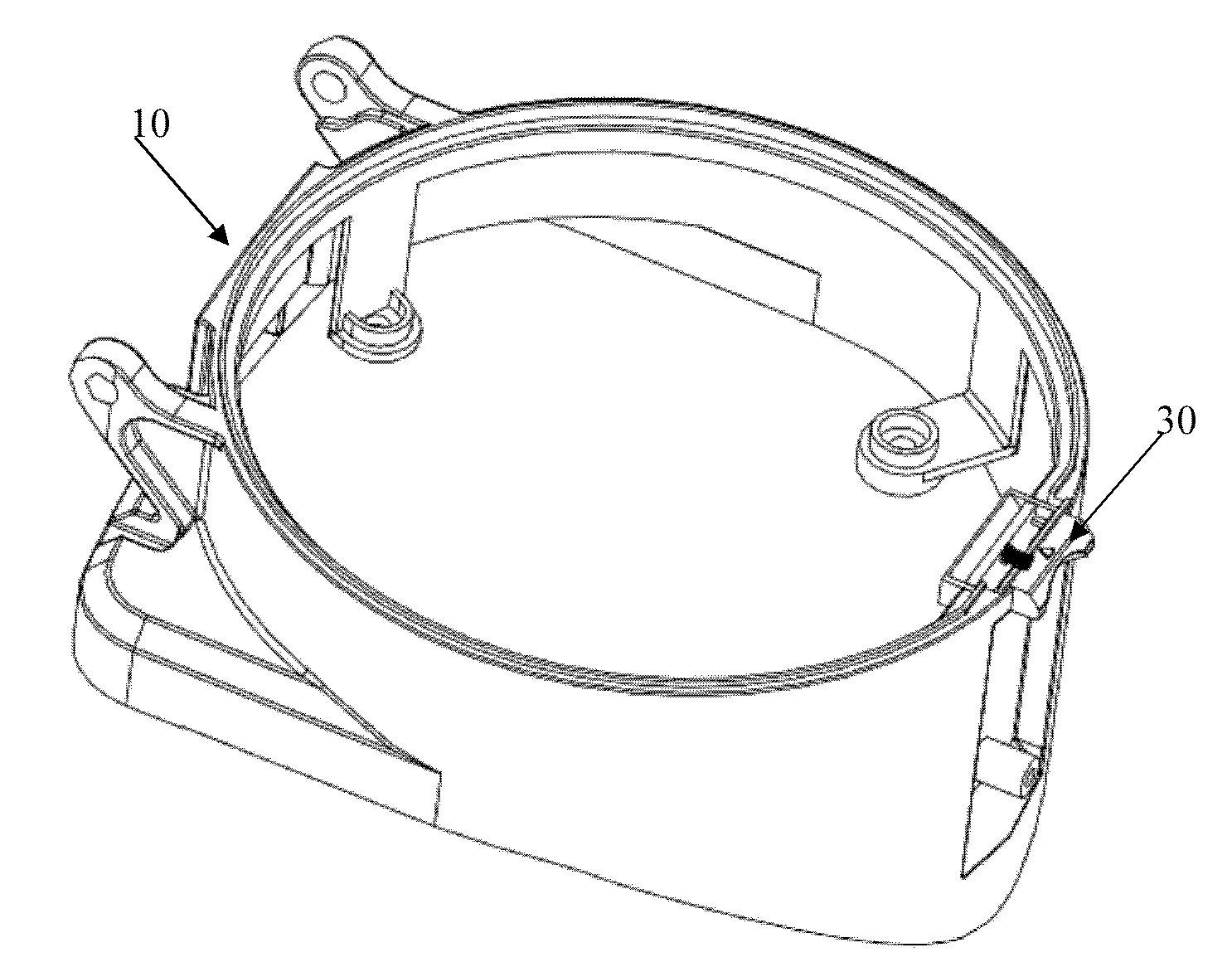

[0021] Such as Figure 1-4 As shown, the installation structure of the high-efficiency air filter of the present invention includes: a shroud 10 that guides the airflow to the motor cavity, a high-efficiency air filter 20 that can be embedded in the installation port 11 of the shroud 10, and The split sliding bayonet structure 30 is arranged on the upper edge of the installation port 11 of the wind deflector. The wind deflector 10 includes the installation port 11 of the high-efficiency air filter 20, and a plurality of support claws 12 integrally formed with the wind deflector 10 and extending inward. The support claws 12 can effectively support the high-efficiency air filter installed in place. The lower edge of the filter effectively ensures the stability of the high-efficiency air filter. The installation opening 11 is a cylindrical structure f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com