Direct Clutch Control for Dual Clutch Transmissions

A dual clutch and transmission technology, applied in the field of clutch systems, can solve problems such as difficulty in differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses.

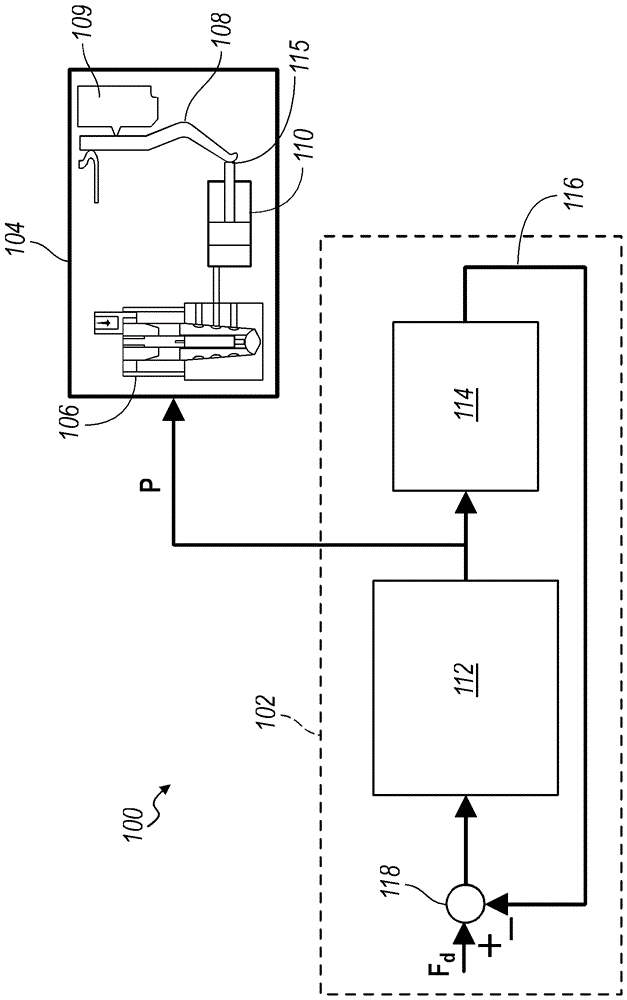

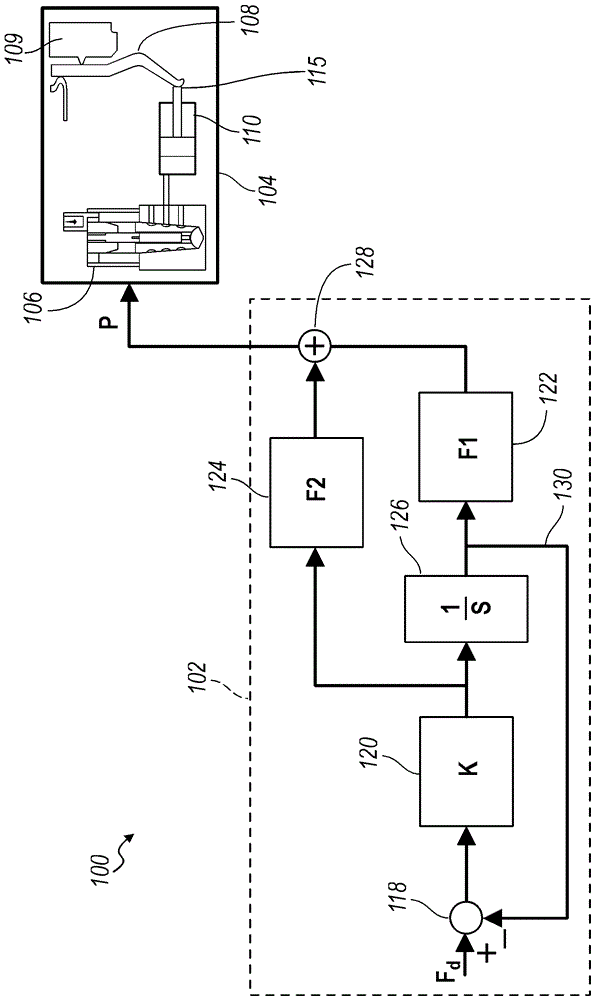

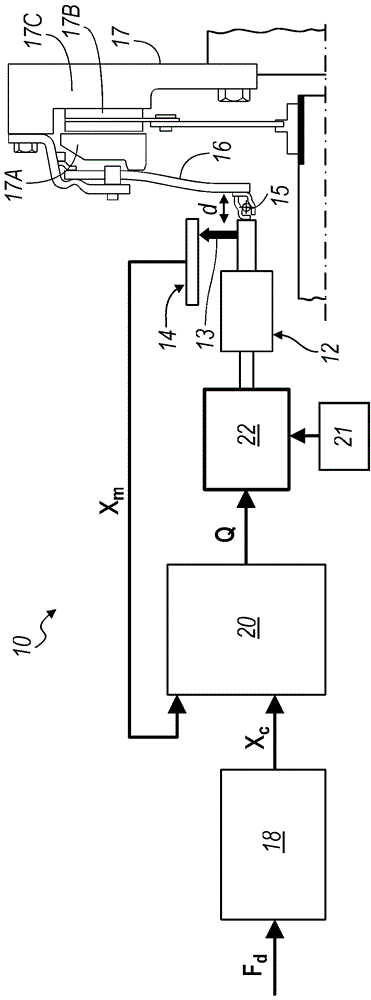

[0044] Referring now to the accompanying drawings, Figure 2 to Figure 4 A clutch control system embodying the principles of the present invention is shown in and indicated at 100, and, for comparison, at figure 1 A conventional clutch control system is shown in , indicated at 10 . These clutch control systems are associated with motor vehicle powertrains, especially dual clutch transmissions.

[0045] A conventional clutch control system 10 includes a hydraulic actuator 12 and a clutch pack 17 . The clutch pack 17 includes a set of clutch plates 17A, 17B, 17C and a diaphragm spring rod 16 . The diaphragm spring rod 16 is in contact with the clutch plate 17A and is coupled to the hydraulic actuator 12 with an applied bearing 15 close to or at the distal end of the diaphragm spring rod 16 .

[0046] System 10 also includes force-position transdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com