Molding device and molding method for producing hollow molded articles

A technology for molding devices and molded products, which is applied in the direction of hollow objects, applications, household appliances, etc., to achieve the effect of improving the sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

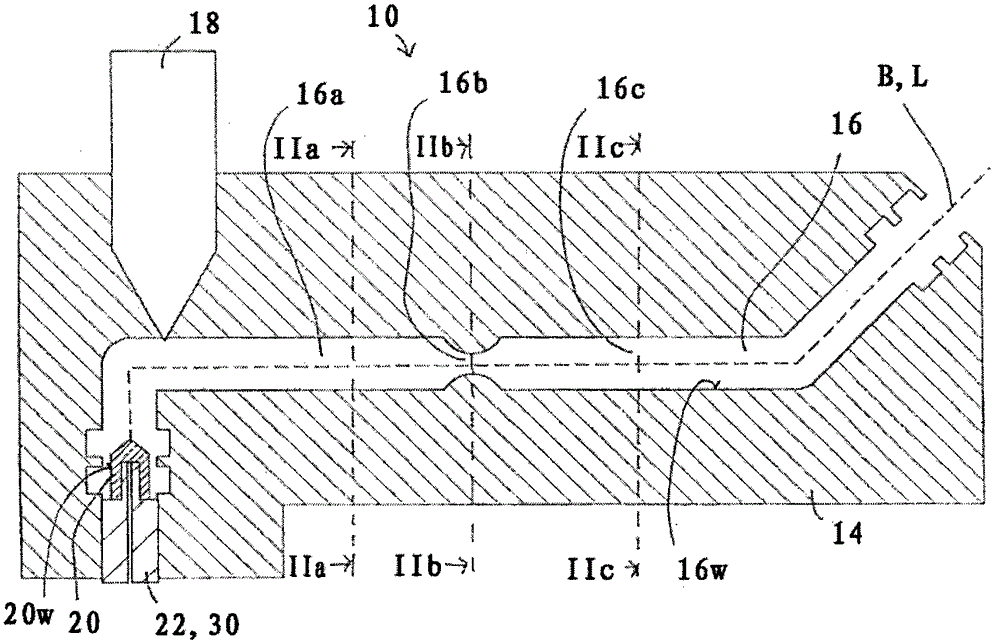

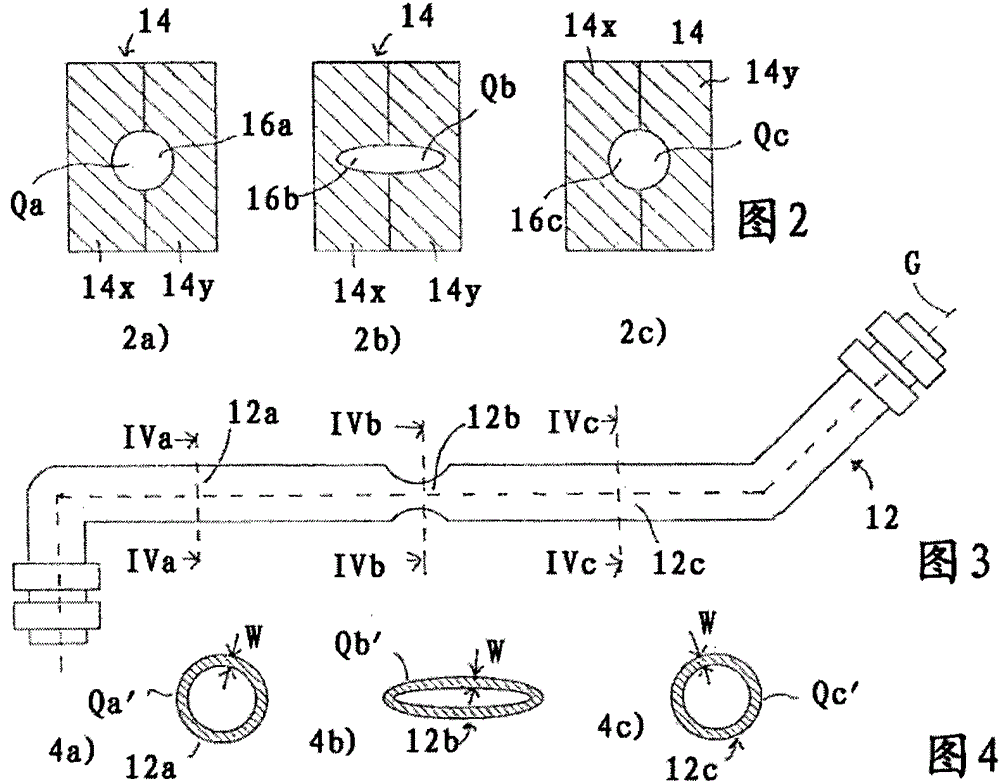

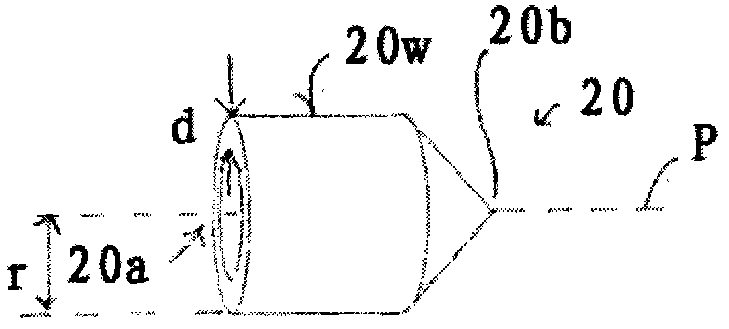

[0051] figure 1 Shows a longitudinal section through a molding device 10 according to a first exemplary embodiment of the invention, comprising a mold 14 with a cavity 16, a filling device 18 for filling the cavity 16 with free-flowing molding material (shown here only very schematically), the ejector body 20 and a displacement device 22 in the form of a nozzle arrangement 30 designed to drive the ejector body 20 along the movement trajectory B into the filled The device 18 is used to fill the mold cavity 16 with molding material.

[0052] The trajectory of motion B takes a curved course, which corresponds to the course of the longitudinal axis L of the mold cavity 16 and the hollow molded article 12 to be produced in the molding device 10 (see image 3 ) axis G (see image 3 )route.

[0053] The mold cavity 16 comprises three mold cavity parts 16a, 16b and 16c, which are arranged successively along the trajectory B of movement. The mold cavity parts 16a and 16b or the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com