Manufacture method of single side ridge type water retaining rubber plate of airplane tire

The invention relates to a technology of aircraft tires and a manufacturing method, which is applied to the manufacturing field of a unilateral ridge water-retaining rubber sheet, which can solve problems such as lack of glue and exposed lines, and achieve the effects of improving service life, improving product quality, and increasing the number of times of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

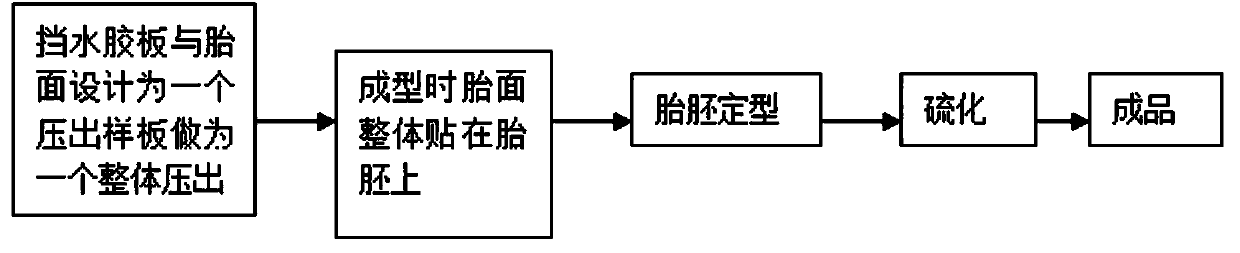

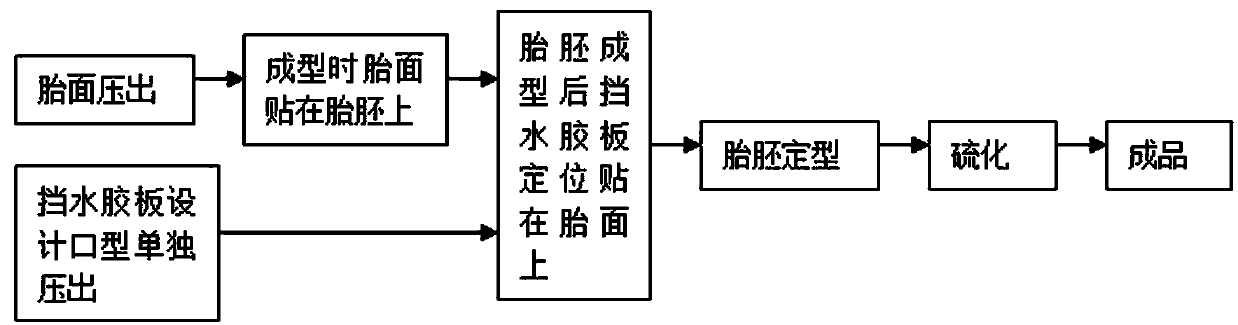

[0020] A method for manufacturing a single-side ridge-type water-retaining rubber plate for an aircraft tire, comprising the steps of:

[0021] (1) The tire vulcanization mold is divided into upper and lower molds. Firstly, the side of the tire with the water-retaining rubber plate is designed to be vulcanized on the lower mold; according to the designed shape of the water-retaining rubber plate, the outlet shape of the water-retaining rubber plate is designed for use in Extrude the water retaining rubber strip on the extruder;

[0022] (2) Pre-treat the surface of the shaped tire from the sidewall to the shoulder, as well as the bonding surface of the water-retaining rubber strip and the tire, by brushing with gasoline and brushing with a wire brush to remove the surface. Impurities, release agents, etc., to ensure the quality of finished products;

[0023] (3) After cutting the water-retaining rubber strip to a fixed length, connect it into a ring shape, and brush the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com