Watchband and producing method thereof

A wristband and baseband technology, which is applied to watchbands, chemical instruments and methods, bracelets, etc., can solve the problems of costly, easy to fall off, and loose joints, etc., and achieve the effects of long service life, cost reduction, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

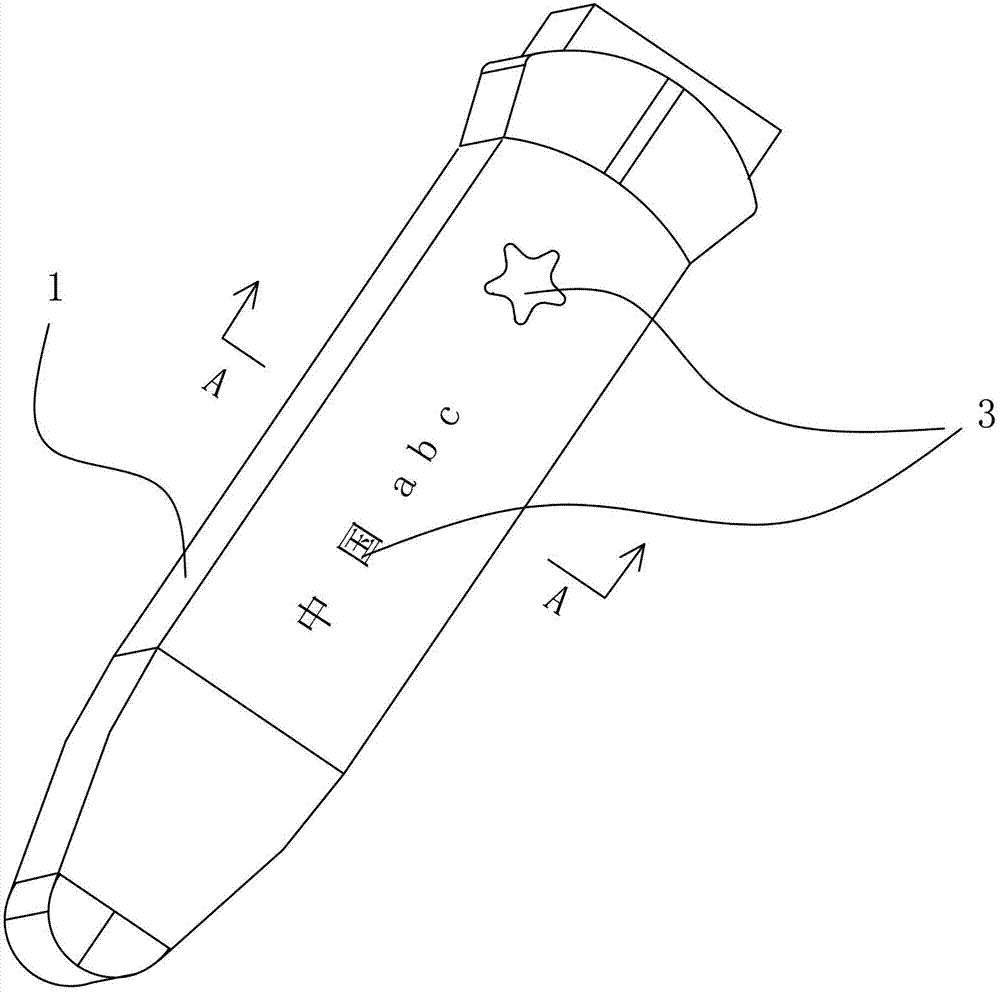

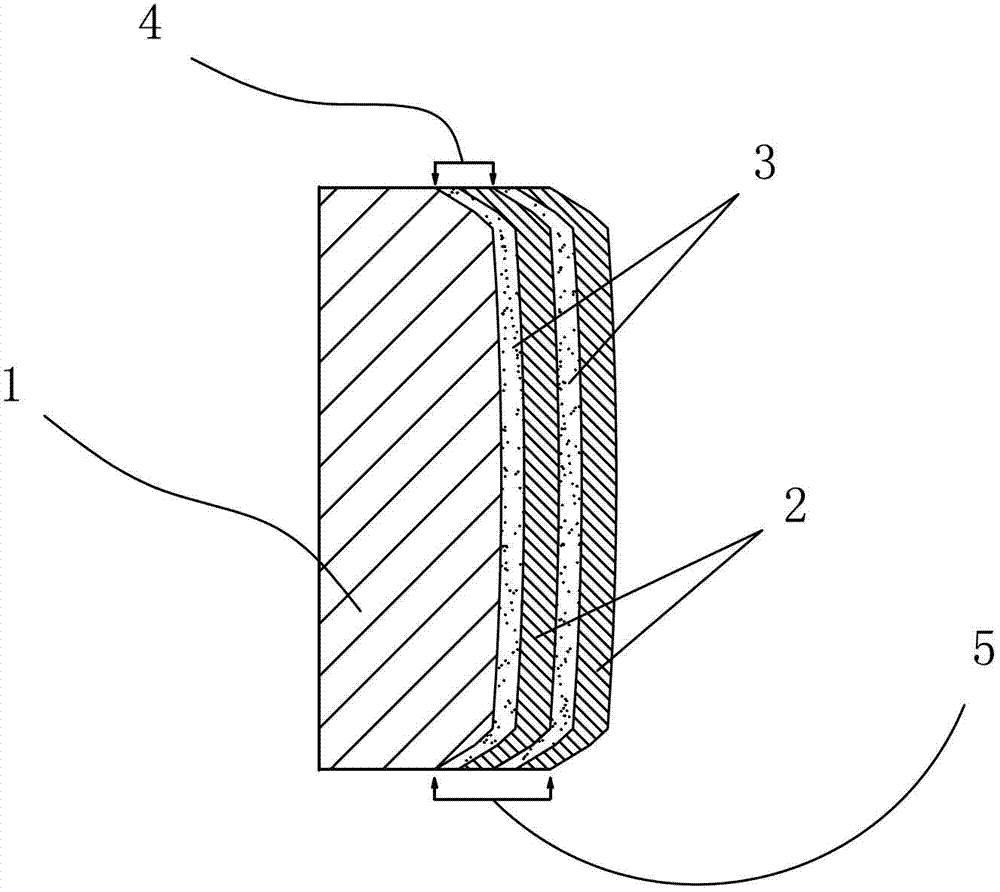

[0033] Such as figure 1 , 2 As shown, the watch band of the present invention is composed of a watch base band 1 and a composite layer 5 printed with text patterns.

[0034] The base belt 1 is made of a silicone material, and the silicone is liquid silicone, liquid silicone rubber, vinyl silicone rubber, low phenyl silicone rubber or fluorosilicone rubber.

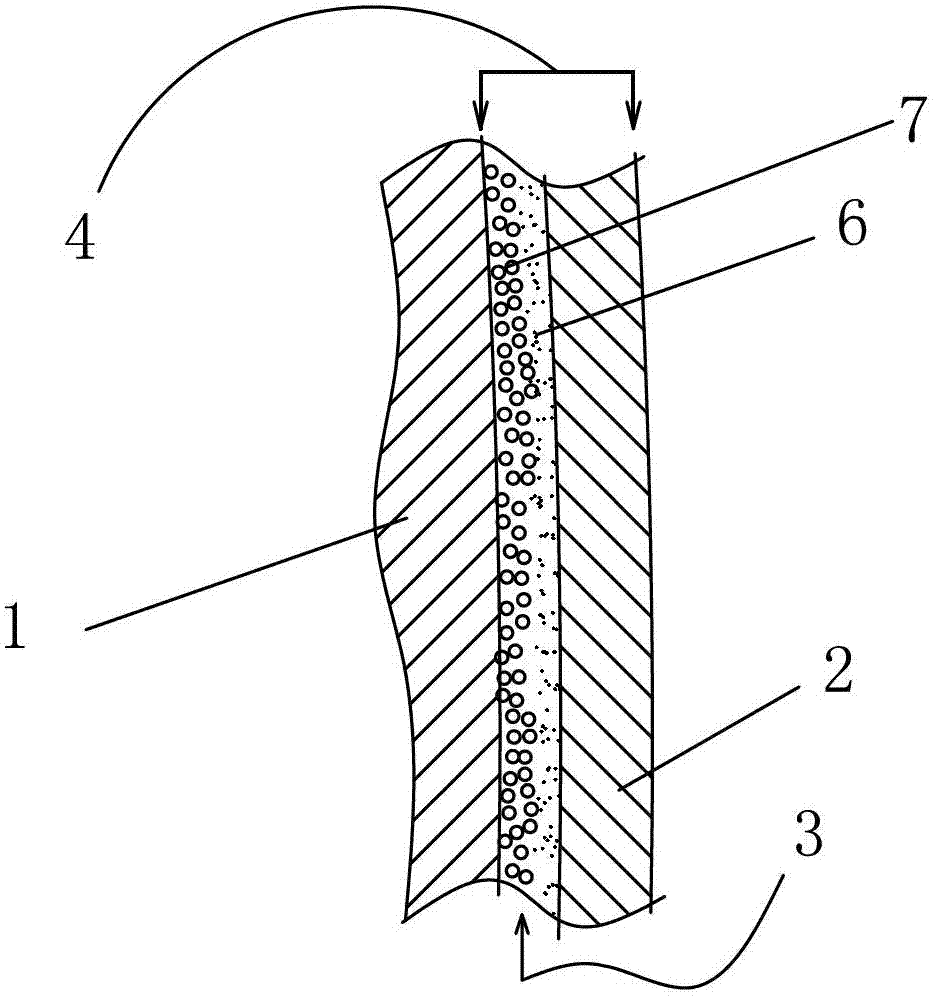

[0035] The composite layer 5 is composed of at least one unit composite layer 4, and each unit composite layer 4 is composed of a text pattern ink layer 3 and a film 2 having a certain thickness.

[0036] The text pattern ink layer 3 is formed by combining the text pattern layer 6 and / or the adhesive layer 7.

[0037] The character pattern layer 6 is made by ink printing or coating.

[0038] The adhesive layer 7 can be a hot sol film or coating, a hot vulcanized adhesive coating or a hot vulcanized catalyst coating. Its function is to bond the resin film or silica gel film, the character pattern layer 6 and the silica gel base tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com