Manufacturing method of concrete precast pile

The technology of a concrete prefabricated pile and a manufacturing method is applied in the directions of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., and can solve the problems of binding steel cages, inconvenient formwork support, lack of steam curing equipment, and poor product quality. Achieve the effect of low labor intensity, novel and practical design, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Embodiment 1: A manufacturing method of prestressed concrete precast piles, which includes the following steps:

[0030] 1. Concrete production (conventional process): build a concrete mixing station and prepare concrete according to the technical requirements of precast concrete piles;

[0031] 2. Pile-body reinforcement cage production (conventional process): Reinforcement lashing and welding reinforcement cages are made according to the design and technical requirements of precast concrete reinforcement cages. Reinforcement cages can be manufactured in batches by manual lashing and mechanical seam welding;

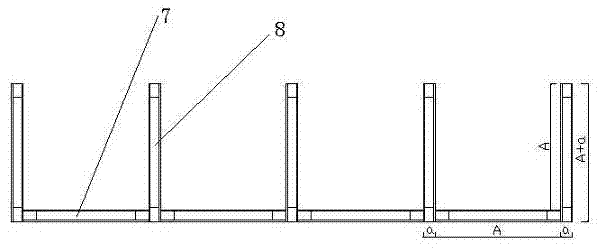

[0032] 3. Construction of steam curing pool and tensioning platform:

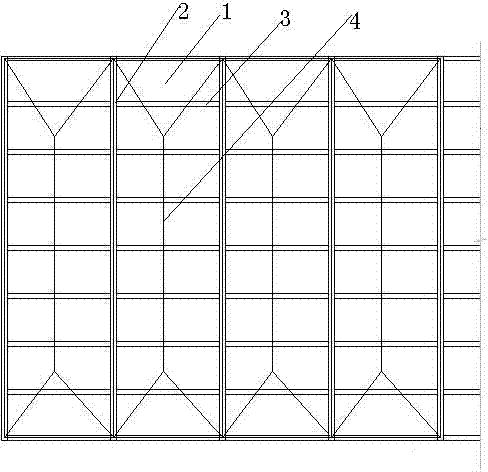

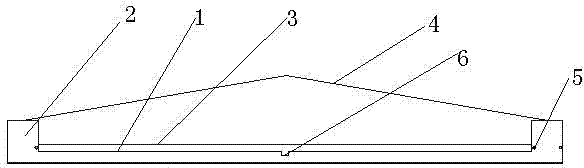

[0033] (1) The steam curing tank is composed of several steam curing units (see figure 1 , figure 2 ), each steaming unit includes steaming pond bottom 1, steaming pond bottom 1 is connected to steaming pond wall 2, steaming pond bottom 1 is evenly distributed with counter beams 3, steaming pond wall ...

Example Embodiment

[0047] Embodiment 2: A method for manufacturing non-prestressed concrete precast piles, which includes the following steps:

[0048] 1. Concrete production (conventional process): build a concrete mixing station and prepare concrete according to the technical requirements of precast concrete piles;

[0049] 2. Pile-body reinforcement cage production (conventional process): Reinforcement is made according to the design and technical requirements of precast concrete reinforcement cages, and lashed and welded reinforcement cages. Reinforcement cages can be manufactured in batches by manual lashing, mechanical roll welding, etc.;

[0050] 3. Construction of steam curing pool:

[0051] The steam curing tank is composed of several steam curing units (see figure 1 , figure 2 ), each steaming unit includes steaming pond bottom 1, steaming pond bottom 1 is connected to steaming pond wall 2, steaming pond bottom 1 is evenly distributed with counter beams 3, steaming pond wall 2 is equipped with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap