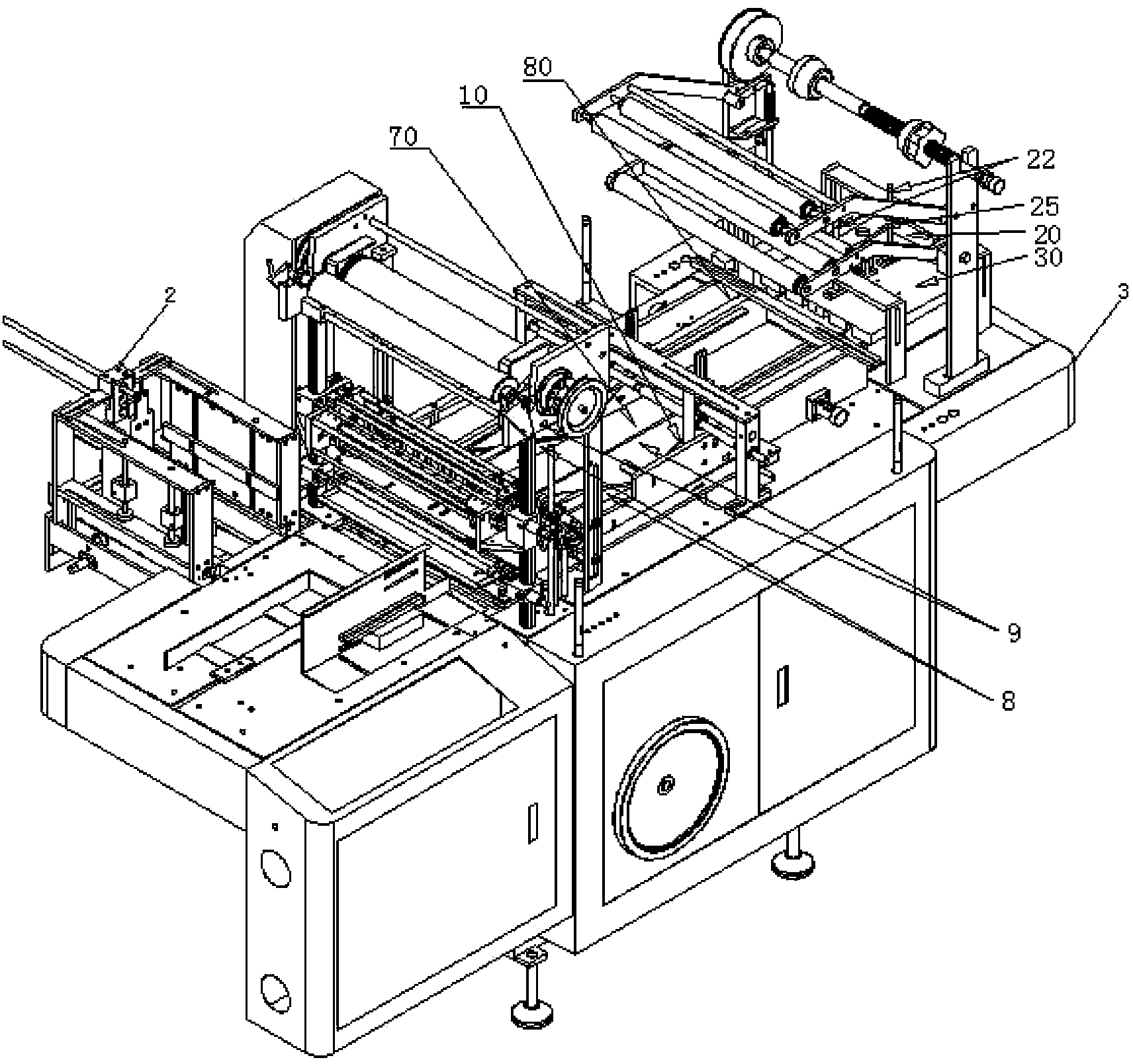

Three-dimensional packaging machine

A three-dimensional packaging and three-dimensional packaging technology, applied in the field of packaging machinery, can solve the problems of restricting packaging quality, affecting packaging effect, and easy to produce looseness, etc., and achieve the effect of smooth packaging process, firm packaging effect and stable mechanical action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

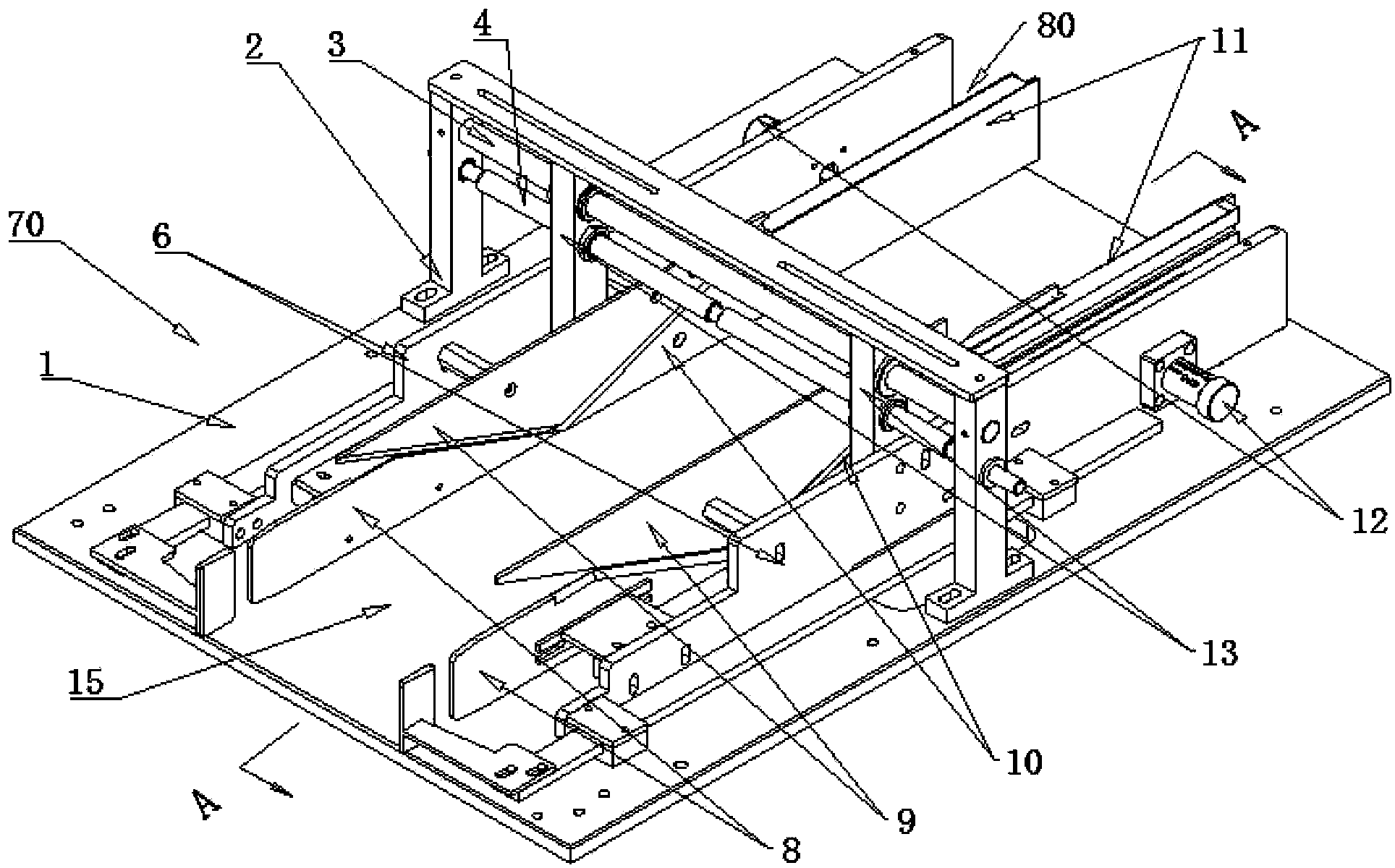

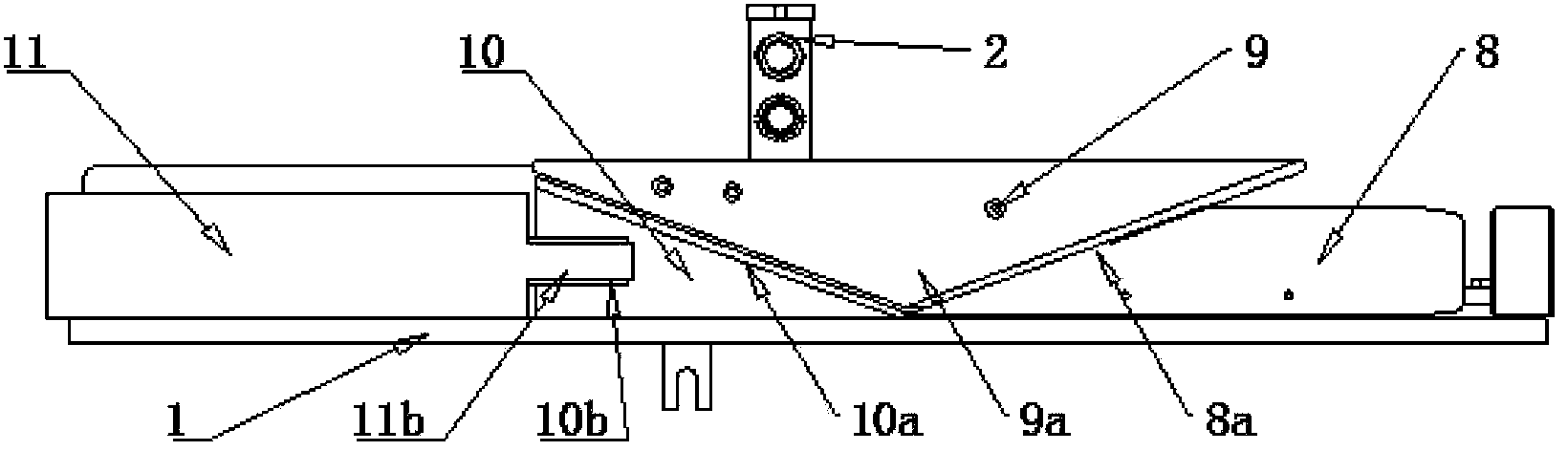

[0017] The lower end 9a of the middle 9 of the folded film plate corresponds to the V-shaped notch formed by the opposite end hypotenuses 8a and 10a of the folded film plate 8 on the same side of the feed channel 15 and the corresponding rear 10 of the folded film plate. Located between the folding film plate 8 and the corresponding folding film plate rear 10, the rear end of the folding film plate 10 is provided with a rectangular or rectangular notch type pre-ironing opening 10b in the front and rear direction.

[0018] The middle 9 of the folding film plate, the back 10 of the folding film plate and the corresponding side ironing cylinder 12 located on the same side of the feed channel 15 are respectively connected to the adjusting seat 6 of the folding film plate on the corresponding side, and the corresponding adjusting seat 6 of the film folding plate is fixedly connected On the adjusting plate 13 on the corresponding side; the guide rod 3 and the screw rod 4 connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com