Oriented fracturing device for horizontal well

A directional fracturing and horizontal well technology, applied in drilling equipment, wellbore/well components, production fluids, etc., can solve problems such as the inability to meet the needs of horizontal well fracturing and stimulation, and avoid the direction of water layers or water injection lines. The effect of transforming reservoirs and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

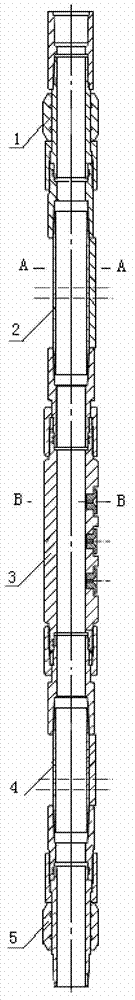

[0023] Embodiment 1: Taking a horizontal well directional fracturing device as an example, the present invention will be further described in detail.

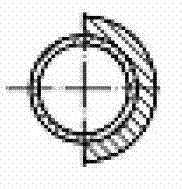

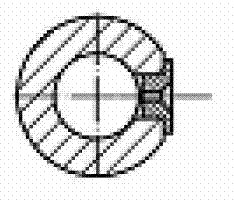

[0024] refer to Figure 1a . Horizontal well directional fracturing device, the first directional spray gun centralizer 1, the first counterweight shaft 2, the directional spray gun 3, the second counterweight shaft 4, and the second directional spray gun centralizer 5 are sequentially connected from top to bottom. The outer diameter of the centralizing part of the first directional spray gun centralizer 1 and the second directional spray gun centralizer 5 is 114mm. The lower joint 19 of the first directional spray gun centralizer 1 is screwed together with the center pipe 21 of the first counterweight shaft 2 . The collar 24 of the first counterweight shaft 2 is threadedly connected to one end of the directional spray gun 3, and the two axial protruding keys 25 of the joint 23 of the first counterweight shaft 2 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com