Fabric one-way surface permeability testing device and testing method

A fiber fabric and testing method technology, applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., can solve problems such as inhomogeneity of fiber preformed permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

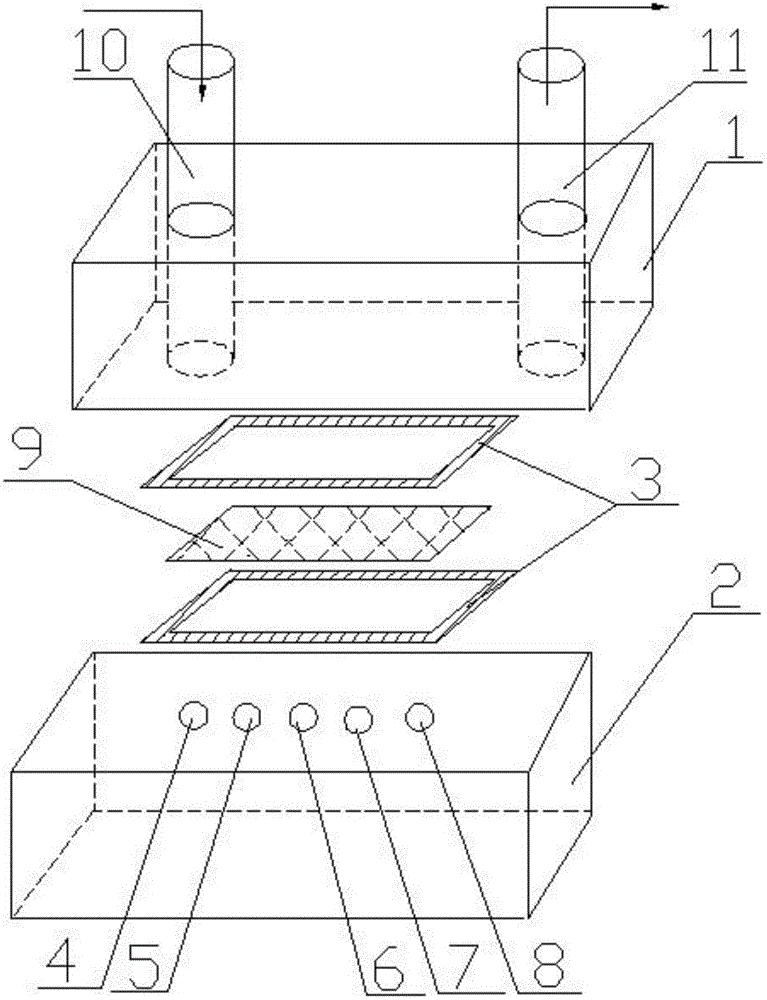

[0037] The fiber fabric unidirectional in-plane permeability testing device of this embodiment includes an upper mold 1, a lower mold 2, a mold cavity thickness support 3, a first piezoelectric sensor 4, a second piezoelectric sensor 5, and a third piezoelectric sensor 6 , the fourth piezoelectric sensor 7, the fifth piezoelectric sensor 8; the cavity thickness support 3 is pressed between the upper mold 1 and the lower mold 2; the first piezoelectric sensor 4, the second piezoelectric sensor 5. The third piezoelectric sensor 6, the fourth piezoelectric sensor 7, and the fifth piezoelectric sensor 8 are linearly distributed on the lower mold in turn, and the fiber fabric 9 is placed in the mold cavity surrounded by the mold cavity thickness support 3, and covers the second piezoelectric sensor. On a piezoelectric sensor 4, a second piezoelectric sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com