Component detection device and component detection method

A technology for detecting devices and components, applied in resistance welding equipment, welding power sources, electrode features, etc., to achieve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

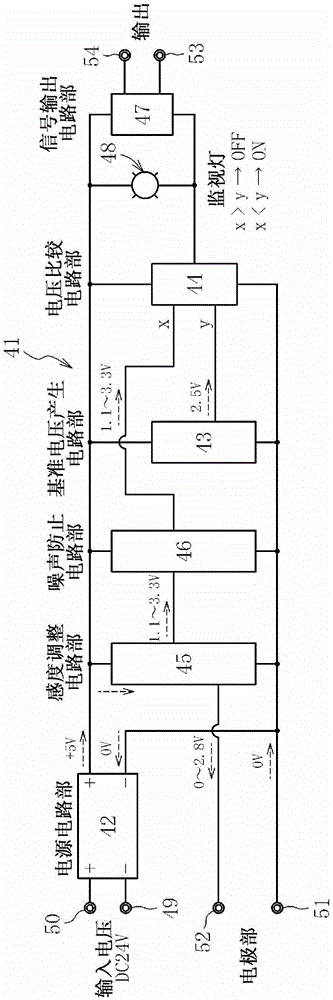

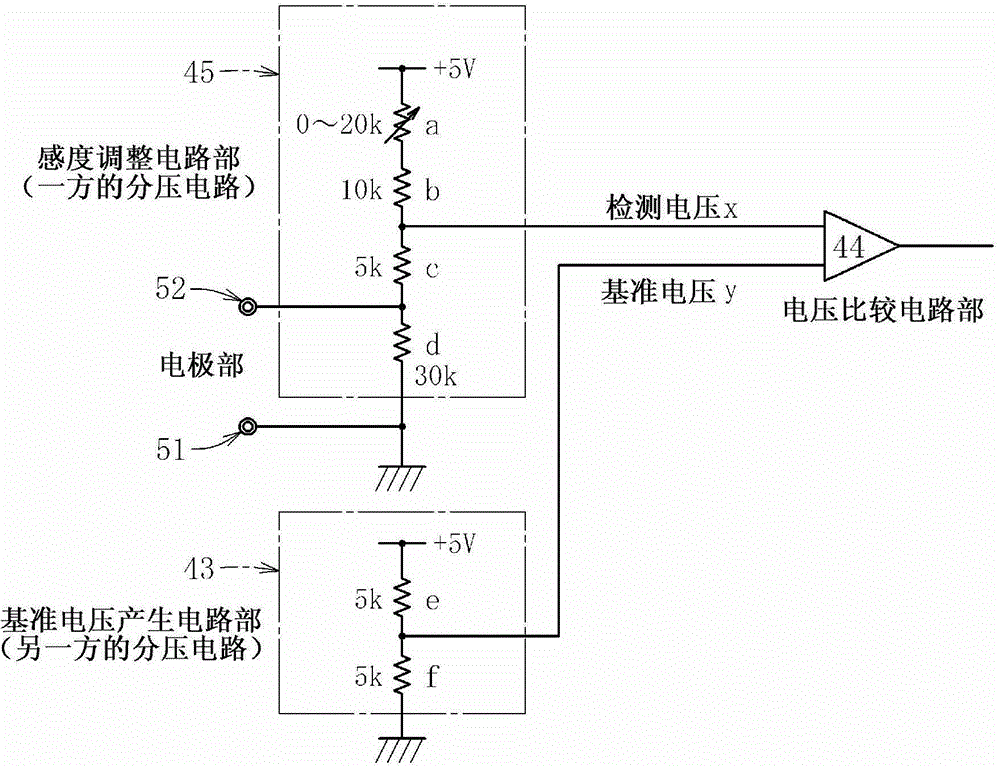

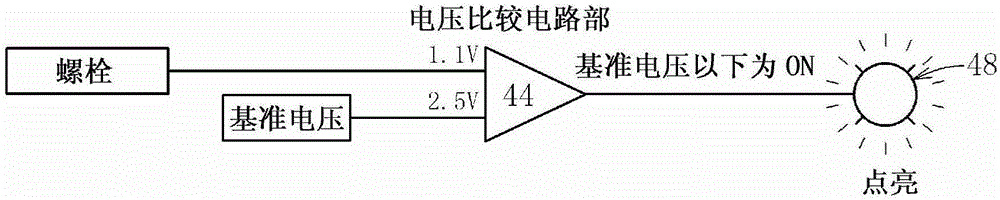

[0040] Hereinafter, embodiments of the component inspection device and the component inspection method of the present invention will be described in detail. In the following embodiments, a component detection device and a component detection method that are attached to an electrode portion of a resistance welding machine for welding bolts to steel plates are exemplified.

[0041] Such as Figure 8 As shown, the iron protruding bolt 1 as the conductive member of this embodiment is a shaft-shaped member, and includes: a shaft portion 2 with a male thread formed on the outer peripheral surface; A circular flange portion 3 ; and a welding protrusion 4 formed on the flange surface opposite to the shaft portion 2 . Among the dimensions of each part, the diameter of the shaft part 2 is 6 mm, the length of the shaft part 2 is 27 mm, and the diameter of the flange part 3 is 14 mm. Further, the counterpart member to which the bolt 1 is welded is a plate-shaped member such as a steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com