Phosphor composite member, LED device and method for manufacturing phosphor composite member

A technology of composite components and manufacturing methods, which is applied in the direction of chemical instruments and methods, semiconductor devices, electroluminescent light sources, etc., can solve problems such as shortened life, low white light, and reduced luminous intensity, and achieve simplified manufacturing processes and improved luminous intensity. Excellent, the effect of suppressing the decline over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

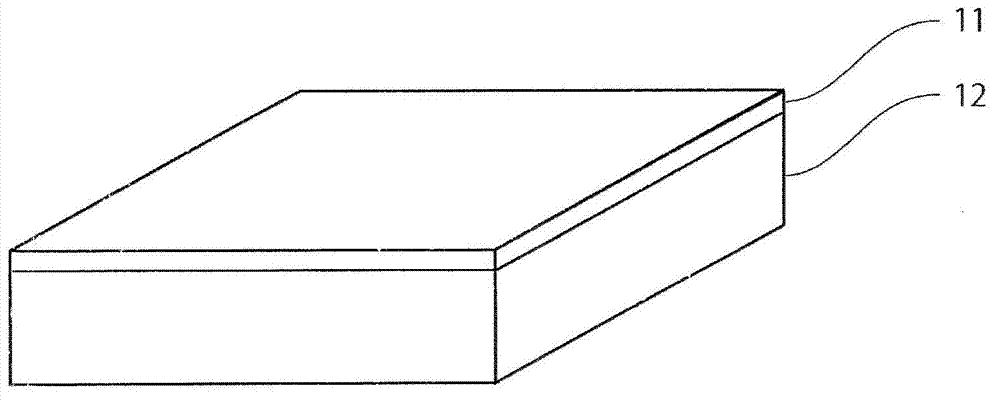

[0066] figure 1 A schematic diagram showing the phosphor composite member of the present embodiment. like figure 1 As shown, the phosphor composite member of this embodiment is characterized in that the surface of the ceramic substrate 12 is formed on the surface of the ceramic substrate 12 2 o 5 The ceramic substrate 12 and the sintered inorganic powder layer 11 emit fluorescence with different wavelengths when irradiated with excitation light.

[0067] Specifically, in the phosphor composite member of this embodiment, it is preferable that the ceramic substrate 12 absorbs light with a wavelength of 400 to 500 nm (preferably blue light) and emits light with a wavelength of 450 to 780 nm (preferably yellow light) when irradiated with excitation light. of fluorescence. In addition, the sintered inorganic powder body layer 11 preferably absorbs light with a wavelength of 400 to 500 nm (preferably blue light) and emits fluorescence with a wavelength of 500 to 780 nm (preferab...

Embodiment )

[0128] Hereinafter, the phosphor composite member of the present invention will be described in detail based on examples, but the present invention is not limited to these examples.

Embodiment 1)

[0130] (1) Preparation of ceramic substrate

[0131] First, using a high-purity raw material with a particle size of 2 μm or less, weigh Y in mole % 2 o 3 37.4625%, Al 2 o 3 62.5%, Ce 2 o 3 0.0375%, making it comply with YAG (Y 3 Al 5 o 12 ) stoichiometric composition, to which 0.6% by mass of tetraethoxysilane was added as a sintering aid. Then, the prepared raw materials were stirred and mixed in ethanol for 17 hours using a ball mill, and then dried under reduced pressure to obtain powder. Next, the obtained powder was press-molded at a pressure of 200 MPa to produce a press-molded body with a diameter of φ10 mm and a thickness of 3 mm, which was fired at 1750° C. for 10 hours in a vacuum atmosphere to obtain a fired body. Then, the fired body was ground on both sides to a thickness of 0.1 mm to obtain a ceramic base material.

[0132] Precipitated crystals were identified using an X-ray powder diffractometer on the ceramic base material thus obtained, and sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com