Rapid pipe fitting clamping method and pipe wrench

A pipe fitting and clamping technology, which is applied in the field of fast clamping pipe fittings and pipe wrench, can solve the problems of fast and reliable clamping and releasing of pipe fittings, achieve fast and reliable clamping and releasing of pipe fittings, fast and reliable operation, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

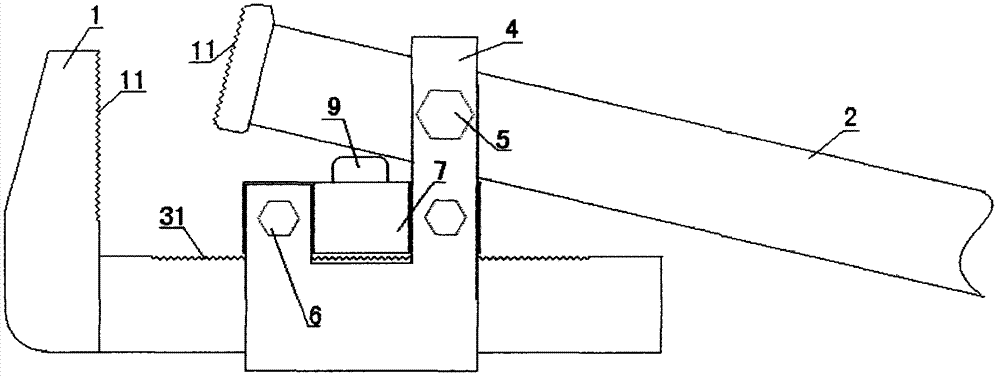

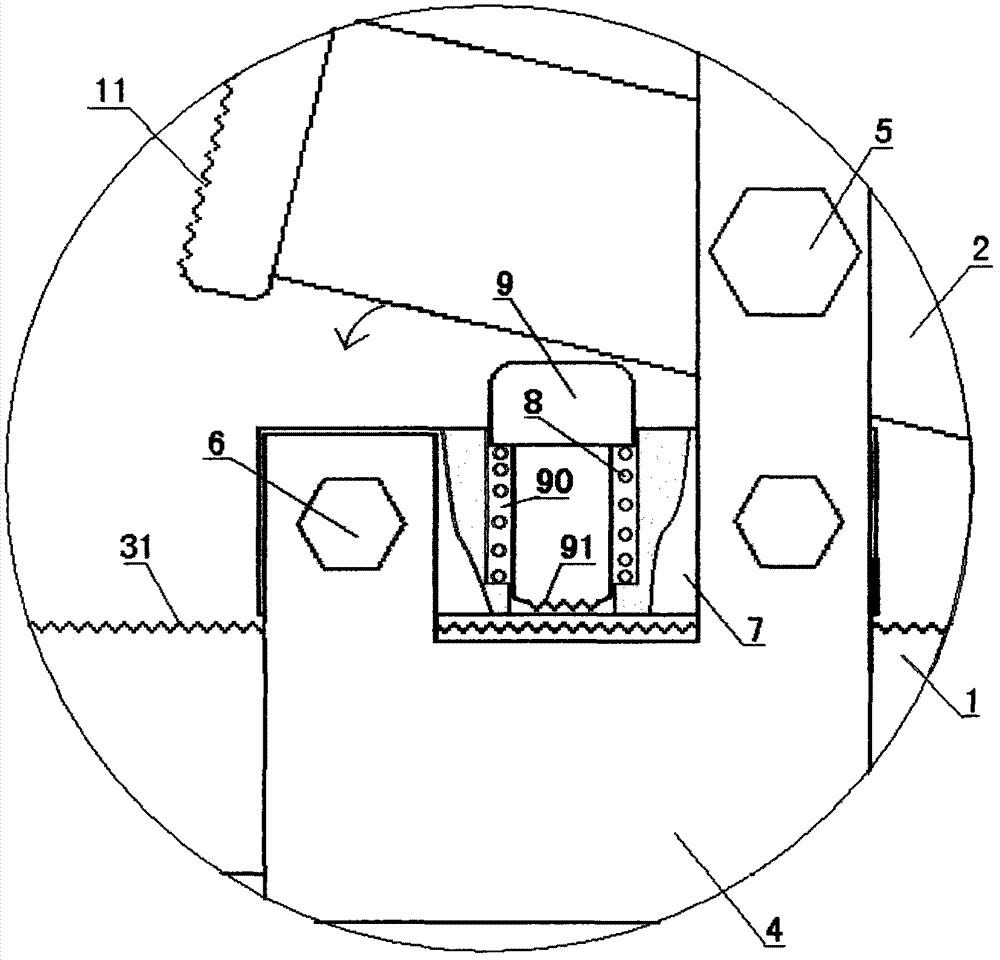

[0018] The fast clamping pipe fitting method of the present invention realizes locking or releasing the jaws by pressing down or lifting the pliers handle hinged with the pliers cover, and realizes the size adjustment of the jaws through the relative sliding of the pliers cover and the handle section of the L-shaped pliers head; The above-mentioned locking jaw is that the pincer handle that presses down presses the locating pin that restricts the limit row of teeth at the end to the locating row of teeth that are formed on the handle section of the L-shaped pliers head, and makes the limit row of the locating pin align with the L-shaped The positioning row teeth of the handle section of the pliers are meshed, and the release jaw is to lift the pliers handle away from the positioning pin, and the positioning pin is kept away from the handle section of the L-shaped pliers under the action of the support spring, and makes the limit row of the positioning pin The teeth are separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com