Heating clamp for steel-plastic composite pipe

A steel-plastic composite pipe and heating fixture technology, which is applied in the field of plastic pipe heating butt joint devices, can solve the problems of harmful gas generation, poor sealing of the pipeline system, poor safety, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

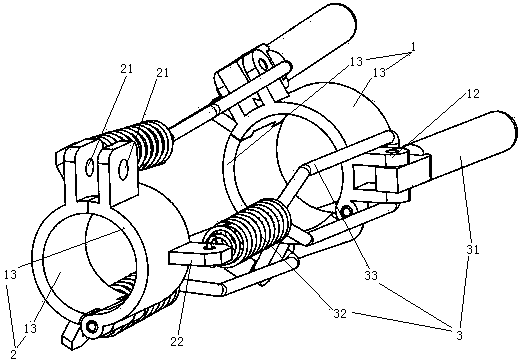

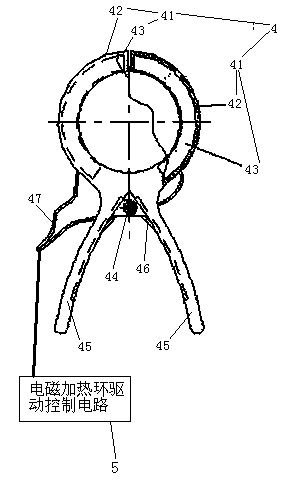

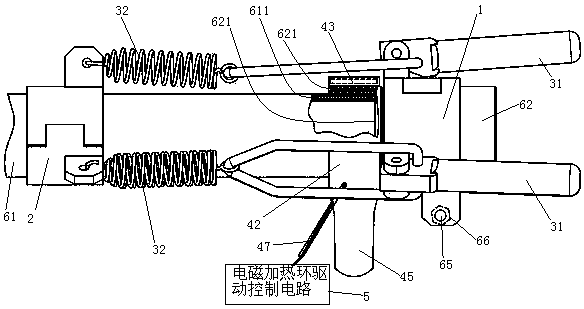

[0028] Embodiment one, see figure 1 , a steel-plastic composite pipe heating fixture, including a clamping mechanism, the clamping mechanism includes two hoops and three axially close structures 3. The three axially close structures 3 are evenly distributed along the circumference of the hoop.

[0029] The two hoops are rear hoop 1 and front hoop 2 respectively. The rear hoop 1 and the front hoop 2 each consist of two semicircular hoops 13 hinged together. The free ends of the two semicircular hoops that constitute the rear hoop 1 are all provided with hoop connecting holes 11 (which are blocked and cannot be seen in the figure). The outer surface of the rear hoop 1 is provided with rear hoop ears 12 . The free ends of the two semicircular hoops forming the front hoop 2 are all provided with hoop connecting holes 21 . Front hoop ears 22 are all provided on the outer surface of the front hoop 2 .

[0030] Axial close structure 3 comprises the first handle 31 that is hinged ...

Embodiment 2

[0033] Embodiment two, see Figure 4 The difference from Embodiment 1 is that the electromagnetic heating ring includes a first electromagnetic heating circular arc piece 48 , a second electromagnetic heating circular arc piece 49 and a third electromagnetic heating circular arc piece 40 located on the same circumference. The circumferential one end of the first electromagnetic heating arc sheet 48 is hinged together with the circumferential end of the second electromagnetic heating arc sheet 49, and the circumferential other end of the second electromagnetic heating arc sheet 49 is connected with the third electromagnetic heating arc sheet. One circumferential end of 40 is hinged together, and a second closing structure 7 is provided between the other circumferential end of the third electromagnetic heating arc sheet 40 and the other circumferential end of the first electromagnetic heating arc sheet 48 . The second folding structure 7 includes a hook head 71 arranged on the t...

Embodiment 3

[0035] Embodiment three, see Figure 6 , the difference with Embodiment 1 is that there are only two axially close structures 3 . The axially approaching structure 3 is a spring. When the front hoop 1 and the rear hoop 2 are fixed on the pipeline and the pipe fitting, the distance between the two is at a position where the spring 32 can be deformed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com